Device for clearing, dispensing and drying of electron components

A technology for electronic components and drying devices, which is applied to devices for coating liquid on surfaces, pretreatment surfaces, coatings, etc., can solve problems such as poor potting, affect activity, and single function, and achieve uniform dispensing. , Improve the quality, the effect of high quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] In order to make those skilled in the art better understand the technical solutions of the present invention, the present invention will be described in detail below with reference to the accompanying drawings. The description in this part is only exemplary and explanatory, and should not have any limiting effect on the protection scope of the present invention. .

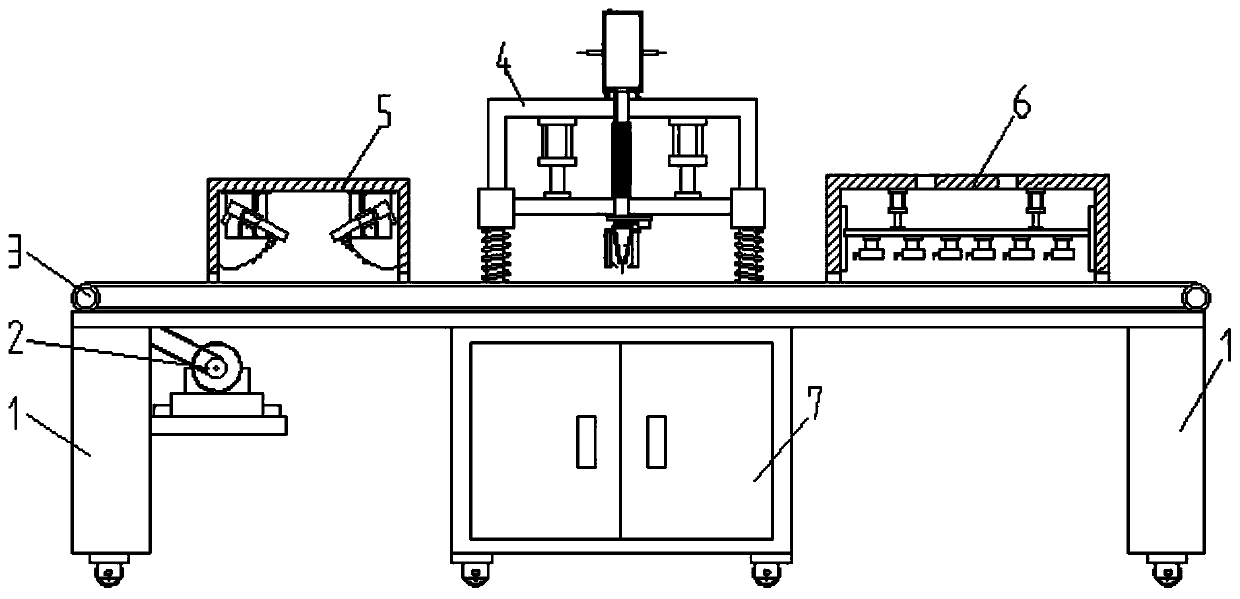

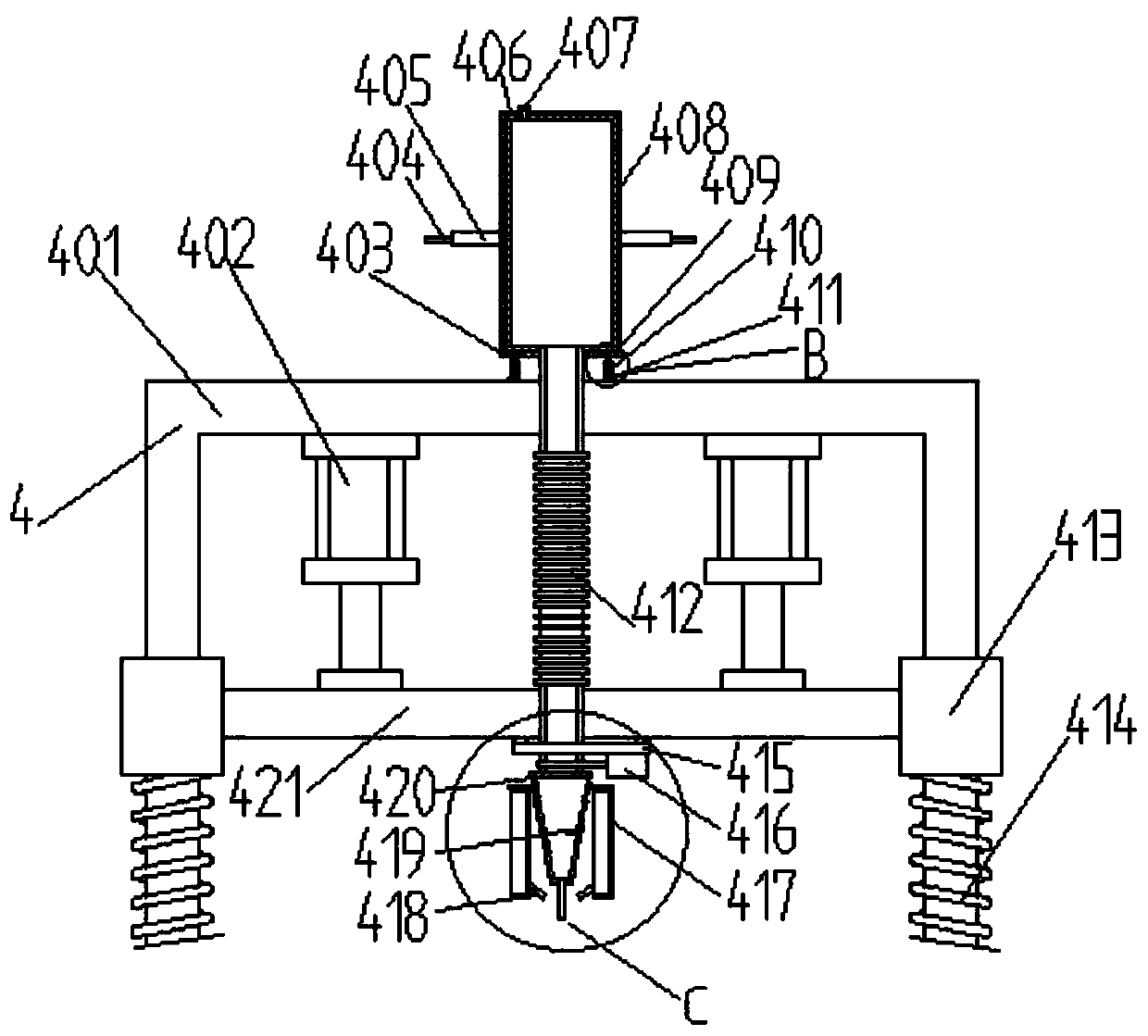

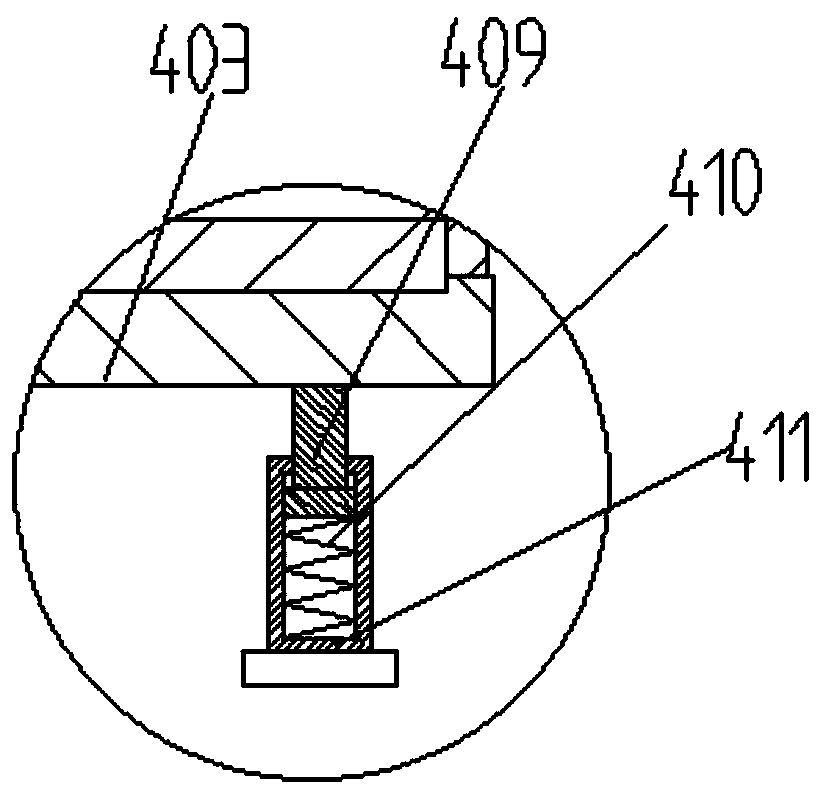

[0035] like Figure 1-Figure 9Shown, the specific structure of the present invention is: it comprises side support frame 1 and intermediate frame 7, and the upper end of side support frame 1 and intermediate frame 7 is provided with transmission device 3, and transmission device 3 is connected with driving device 2; Side support frame 1 A cleaning device 5 and a drying device 6 are respectively arranged on the top, the cleaning device 5 includes a connecting plate 505 arranged on the first frame body 504, a movable sleeve 503 is arranged on the connecting plate 505, and a dust blowing gun is interspersed on ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com