Agricultural grain drying device

A drying device and grain technology, which is applied in drying, drying machines, heating devices, etc., can solve the problems of high requirements, large site area requirements, damp and moldy grains, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

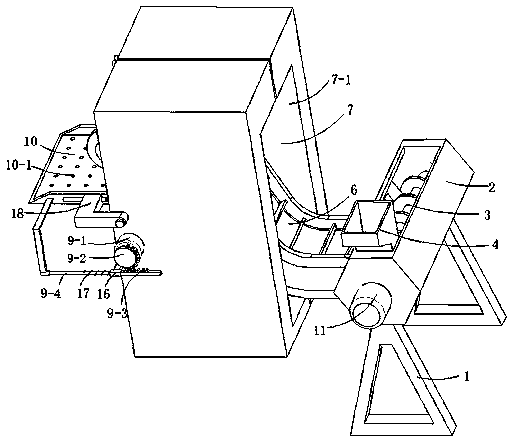

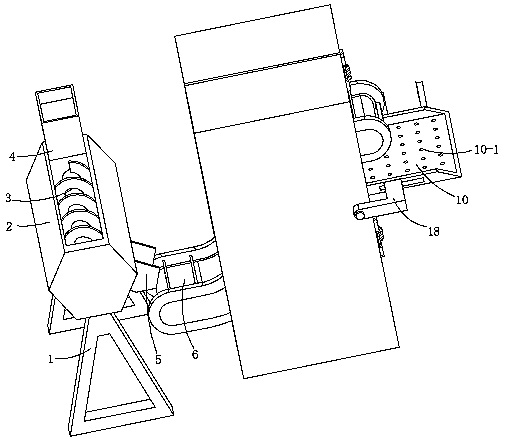

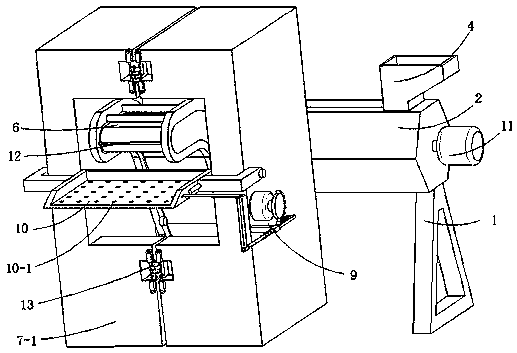

[0035] refer to Figure 1-8 , a grain drying device for agriculture, comprising a conveying bracket 1, a conveying box 2 is fixedly installed on the top of the conveying bracket 1, a screw conveying auger 3 is rotatably connected in the conveying box 2, and a feeding auger 3 is fixedly arranged on the top of the conveying box 2 The bucket 4, the side wall of the delivery box 2 away from the feed hopper 4 is provided with a discharge hopper 5; the bottom of the discharge hopper 5 is provided with a stepped grain conveying mechanism 6, and the outside of the grain conveying mechanism 6 is provided with a drying box 7 for drying The box 7 is specifically two housings 7-1 connected in rotation. The inner wall of the housing 7-1 is provided with a heating pipe 8 distributed in a serpentine shape. The outer wall of the housing 7-1 is also provided with a reciprocating mechanism 9. The output of the reciprocating mechanism 9 A sieve mesh 10 is fixed at the end, and a sieve hole 10-1 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com