Layered type sand and stone screening machine

A screening machine, layered technology, applied in the direction of filtration, solid separation, grille, etc., can solve the problems of time-consuming, manpower, difficult maintenance, high equipment price, etc., and achieve low cost, easy operation and compact structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be described in detail below in conjunction with the accompanying drawings.

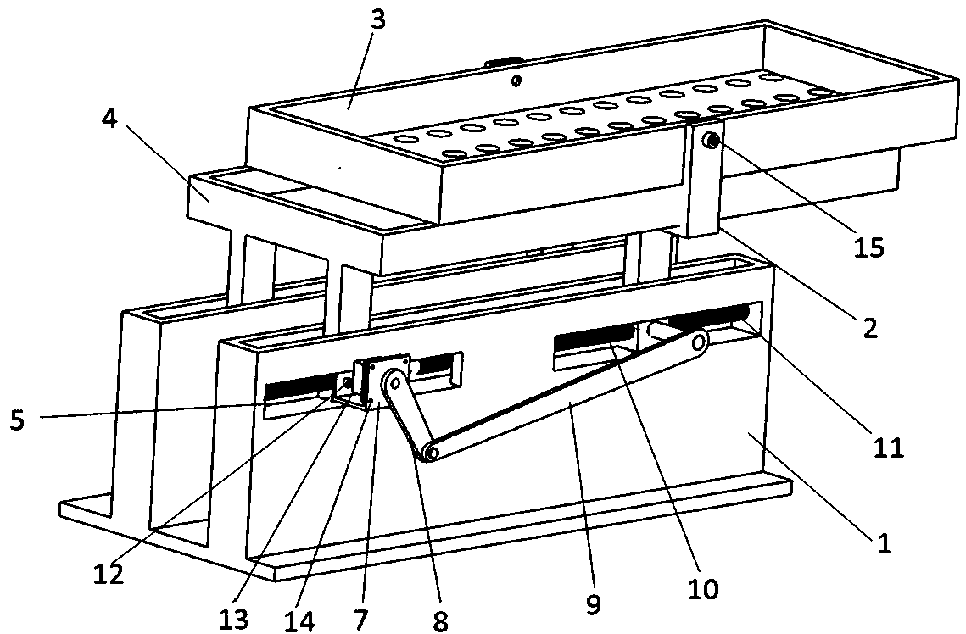

[0018] like figure 1 , a layered gravel screening machine includes a frame body, a screening mechanism, a crank slider mechanism, and a spring extrusion mechanism; the screening frame 3 is fixed on the support frame 2, and is driven by the support frame 2 to slide together; the crank slider The mechanism is arranged on the right slide rail on the frame body 1, and the drive motor 13 drives the crank 8 to rotate, and then drives the support frame 2 to reciprocate; Moving the extruded spring further drives the relative movement of the receiving frame 4 and the screening frame 3 to realize the screening function.

[0019] like figure 2 and image 3 , the right slide rail on the rack body 1 is composed of front pin 1-1, rear pin 1-2, chute 1-1, front notch 1-4, rear notch 1-5, left slide rail It has the same characteristics as the right slide rail and is symmetrical...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com