Supercritical carbon dioxide coal body extraction and deep hole no-coupling charging carbon dioxide medium pressure relief blasting gas control method and device

A carbon dioxide, pressure relief blasting technology, applied in gas discharge, safety devices, extraction fluids, etc., can solve the problems of long charging time, low gas permeability, and prolonged extraction time to reach the standard, and achieve the improvement of single entry level and efficiency, The effect of large gas flow attenuation coefficient and increasing effective excavation time

Inactive Publication Date: 2020-01-21

刘德成

View PDF0 Cites 2 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

But he also has its shortcomings that are difficult to overcome: the aperture of the blast hole is too small, it is difficult to place the charge in place, and it takes a long time to charge the charge, etc.

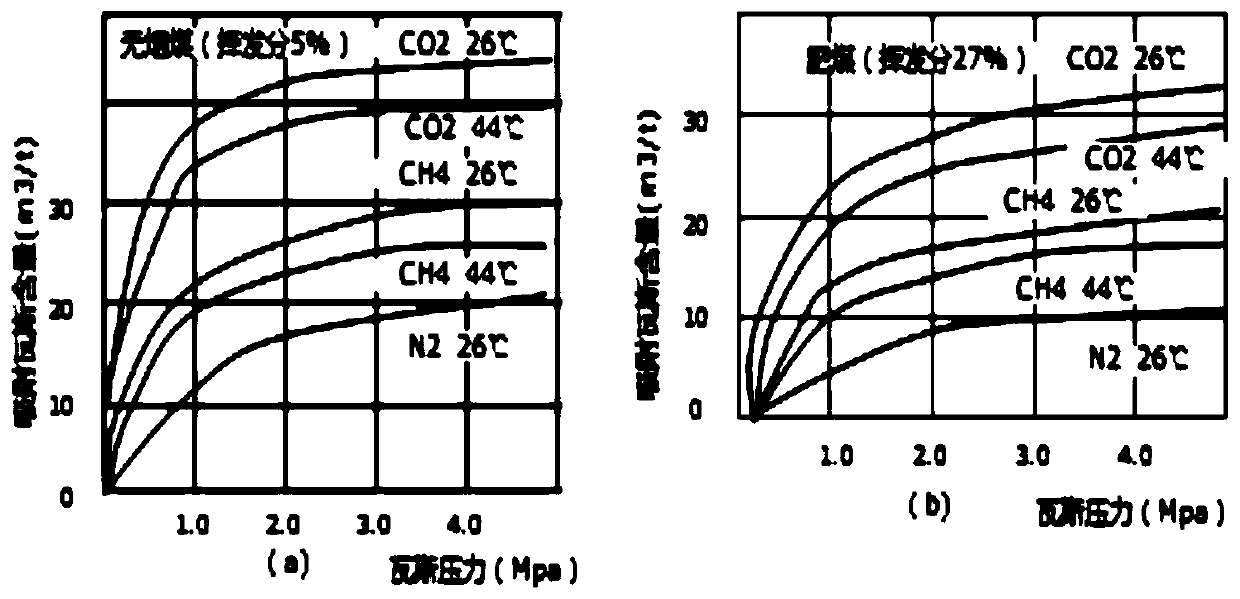

For anth

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Login to View More

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Depth | aaaaa | aaaaa |

Login to View More

Abstract

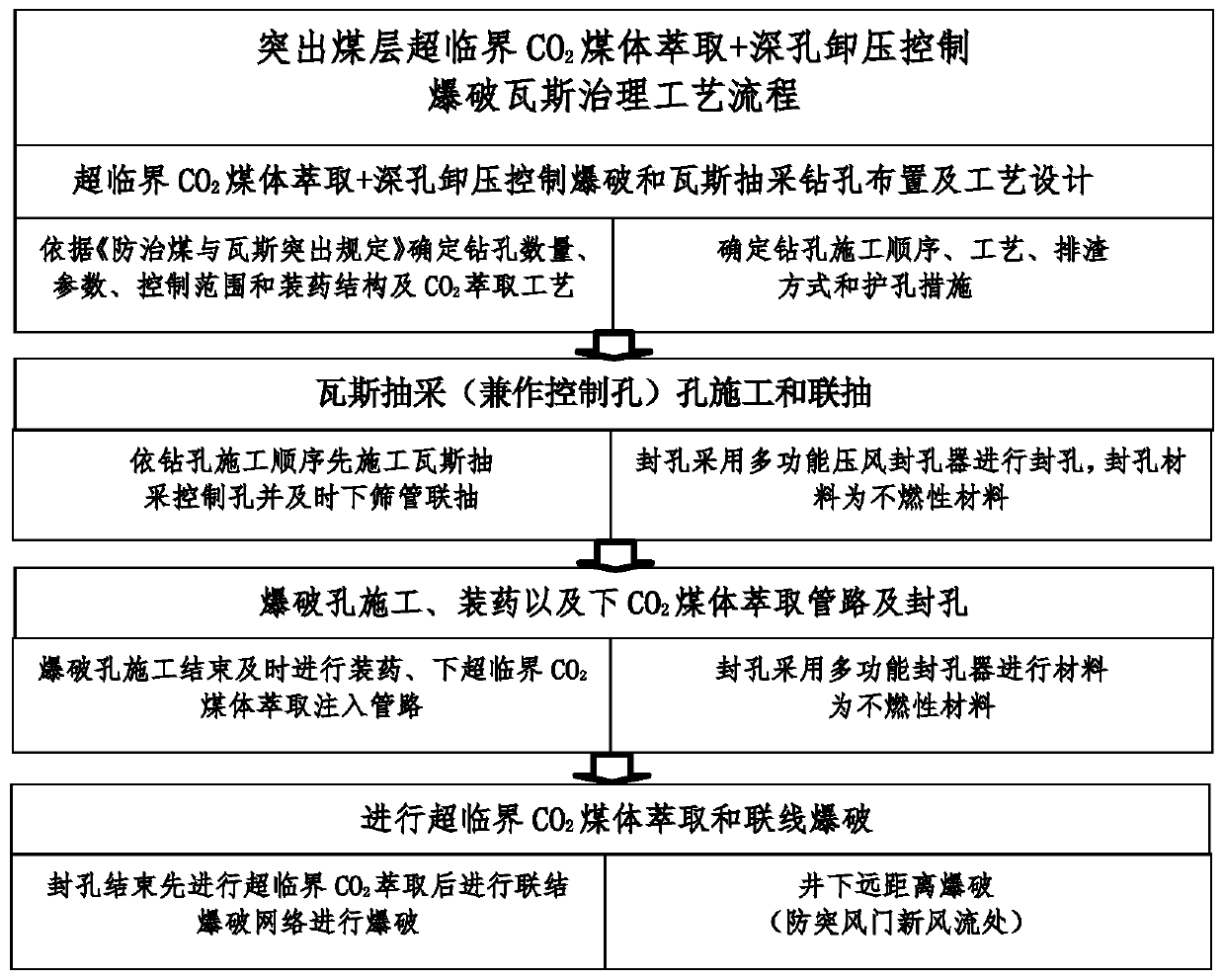

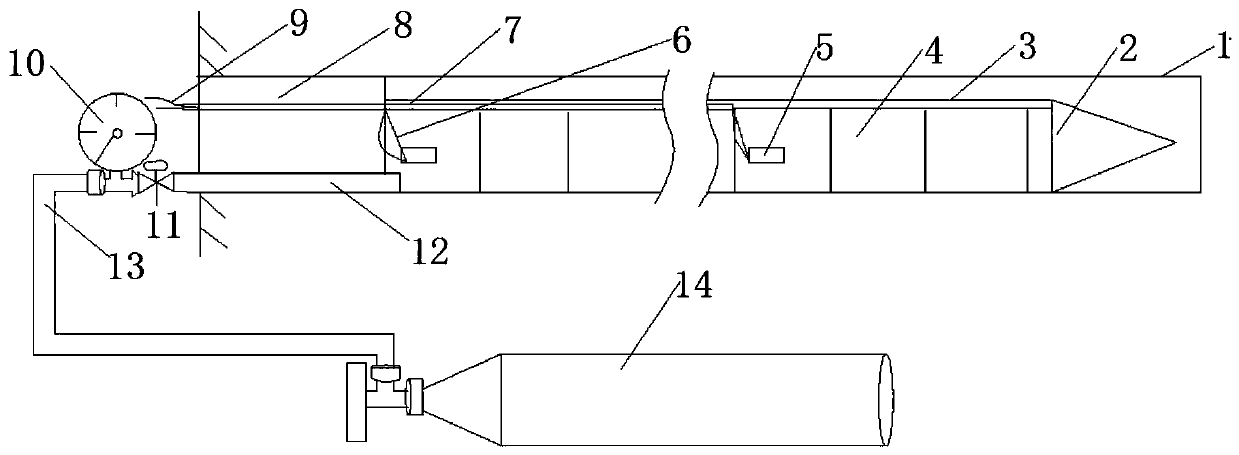

The invention relates to a supercritical carbon dioxide coal body extraction and deep hole no-coupling charging carbon dioxide medium pressure relief blasting gas control method and device. The methodcomprises the following steps that an underground blasting-preventing drilling machine is adopted for constructing a blasting extraction hole in a coal bed, and a blasting material and a supercritical CO2 extraction pipeline are installed in the blasting extraction hole; a hole sealing material is utilized for sealing the blasting extraction hole; the extraction pipeline is utilized for inputtingsupercritical CO2 into the blasting extraction hole for extracting methane in the coal bed; the blasting material in the blasting extraction hole is detonated, and the control process of gas is completed. The method fully utilizes the special physicochemical property of supercritical CO2 and the advantage of deep hole pressure relief control over dynamiting.

Description

technical field [0001] The invention relates to the technical field of gas prevention and control in coal mines, in particular to a gas treatment method and device for pressure relief blasting with supercritical carbon dioxide coal extraction and deep-hole uncoupled charging carbon dioxide medium. Background technique [0002] With the increase of mining depth, coal seam gas content and pressure, low gas mines are transformed into high gas mines, and high gas mines become coal and gas outburst mines. [0003] Coal (rock) and gas outburst are common complex dynamic phenomena in coal mine production. my country is the country with the most serious outbursts in the world, and coal (rock) and gas outbursts have become one of the main threats to the safety of coal mine production in my country. [0004] Since most of the outburst coal seams are low permeability and difficult to extract coal seams, the difficulty of gas extraction and control also increases, and the cost and risk...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): E21B43/00E21B43/16E21B43/26E21B47/06E21F7/00

CPCE21B43/006E21B43/164E21B43/26E21B47/06E21F7/00

Inventor 刘德成刘珂

Owner 刘德成

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com