Surface cleaning head

A surface cleaning and bottom surface technology, applied in cleaning equipment, suction nozzles, vacuum cleaners, etc., can solve the problems of reducing the sealing effect between the surface cleaning head and the surface to be cleaned, the vacuum inlet cannot be cleaned, and the cleaning effect is not ideal, etc., to achieve a good ground Handling performance, good cleaning results, the effect of enhancing the ability to carry debris and dust

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

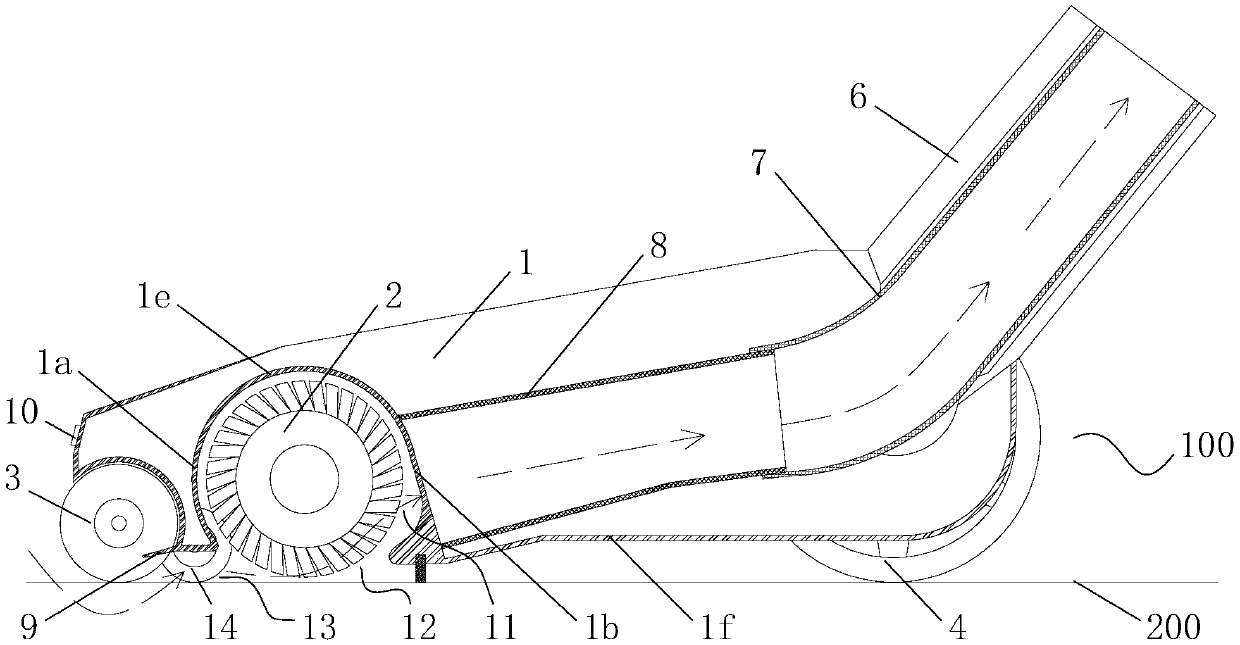

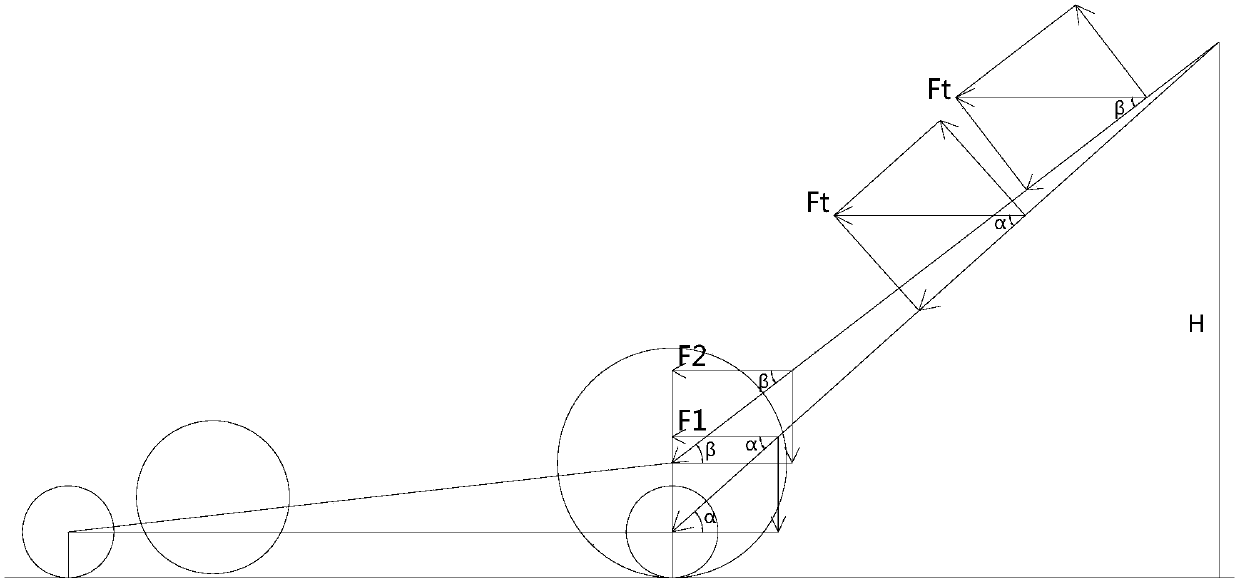

[0026] In order to explain the overall concept of the present invention more clearly, the following will be described in detail by way of examples in conjunction with the accompanying drawings.

[0027] Surface cleaning heads are typically configured to contact a surface in order to clean the surface by using suction airflow, agitation, or a combination of suction airflow and agitation. The surface cleaning head is pivotally or steerably coupled by a swivel connection to a cleaning head joystick for controlling the surface cleaning head, the surface cleaning head may also be operated without a cleaning head joystick or handle. When the specified surface cleaning head is used, the side close to the surface to be cleaned is the lower side; when the specified surface cleaning head is used, the direction in which the user pushes the surface cleaning head forward is the front, and the user applies a pulling force to pull the surface cleaning head back in the direction of rear. As ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com