Shoe fitting belt assembly line

A technology for assembly lines and shoes, applied in the application, footwear, shoe-making machinery and other directions, can solve the problems of glue overflow, poor quality, sticking together, etc., to save waste and avoid glue overflow.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

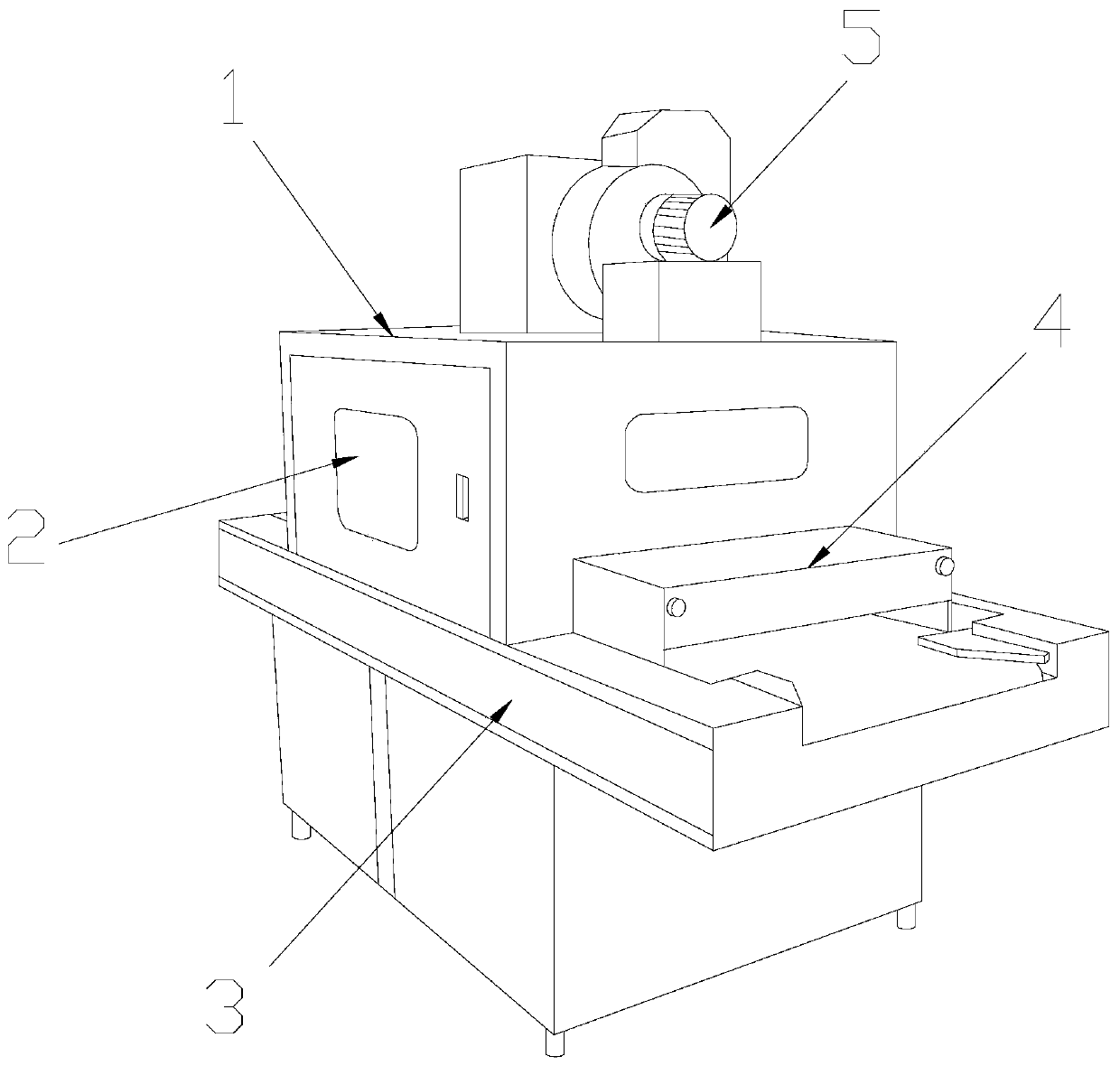

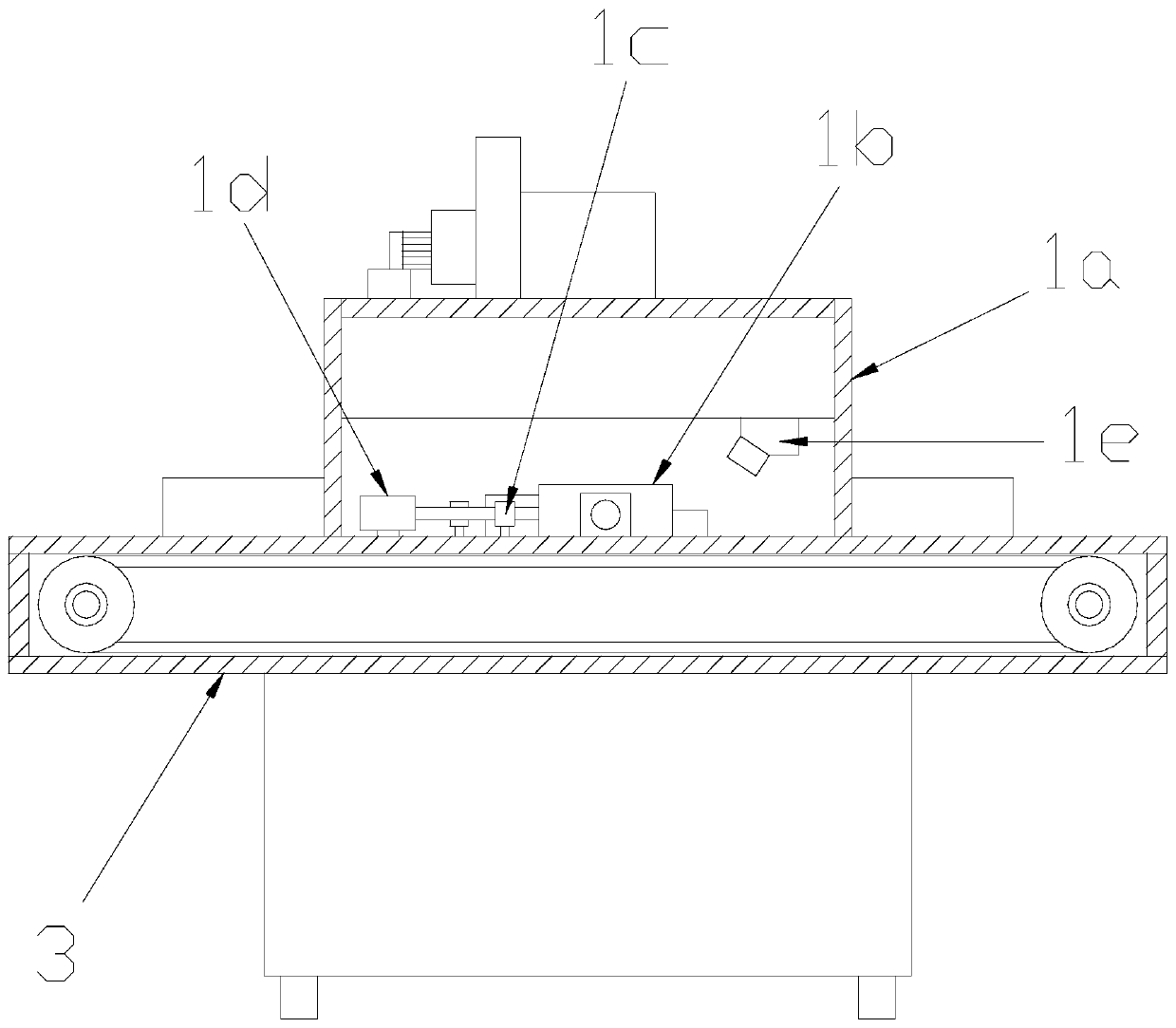

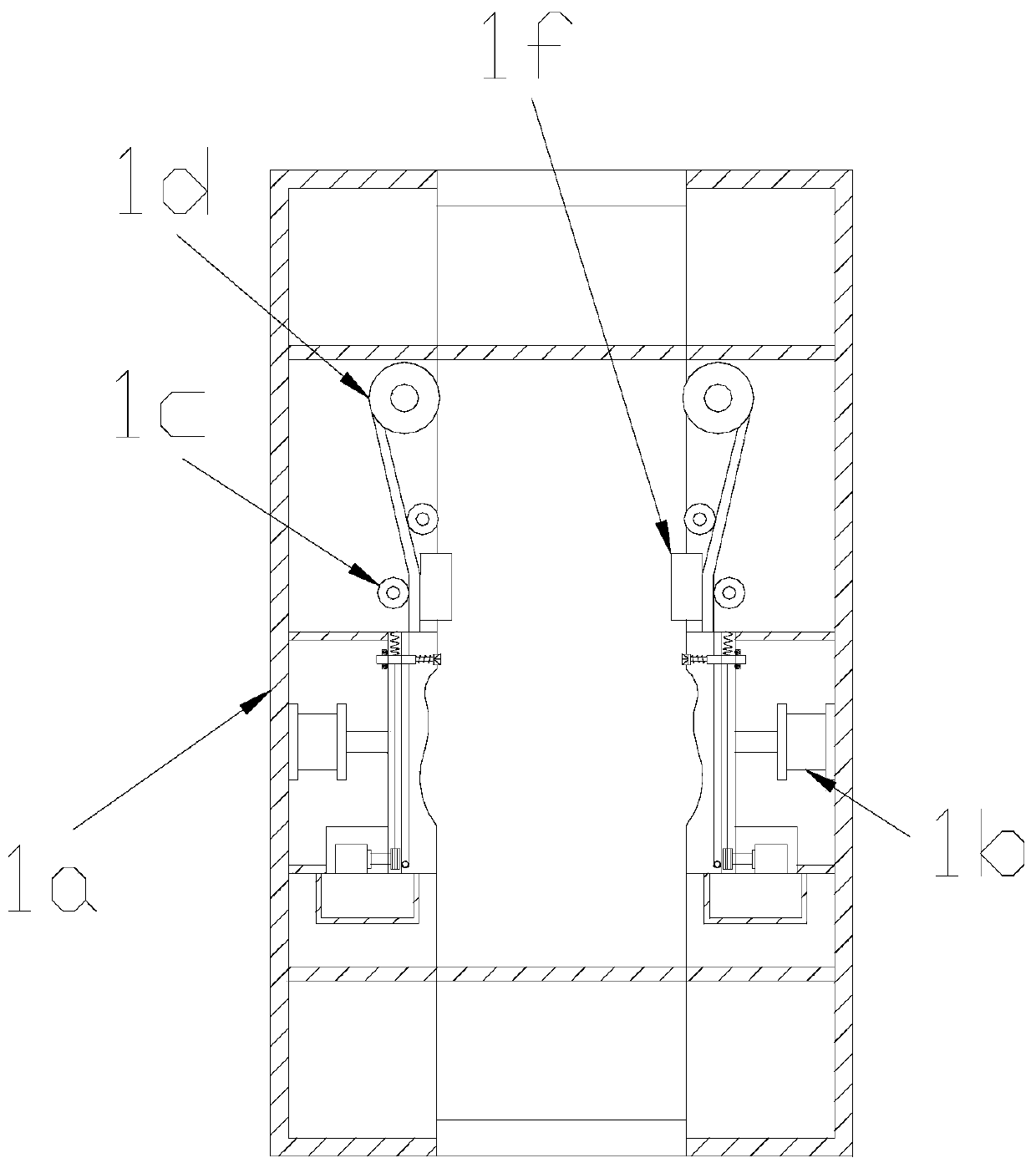

[0028] see Figure 1-Figure 7 , the present invention provides a shoe laminating belt assembly line, the structure of which includes a shoe laminating machine 1, an inspection door 2, a conveyor 3, a dust cover 4, and a fan 5. The front end surface of the shoe laminating machine 1 is An inspection door 2 is installed on the top, and the left and right sides of the shoe laminating machine 1 are provided with dust covers 4, and the shoe laminating machine 1 and the dust cover 4 are welded by electric welding. A fan 5 is arranged on the top of the shoe laminating machine 1, the shoe laminating machine 1 and the fan 5 are flexibly connected, and a conveyor 3 is installed inside the shoe laminating machine 1, and the shoe laminating machine 1 The closing machine 1 is composed of a body 1a, a fitting mechanism 1b, a guide wheel 1c, a belt reel 1d, a heating fan 1e, and a miniature glue spraying machine 1f. Two fitting mechanisms 1b are installed at the inner bottom of the body 1a. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com