Display screen module bottom shell

A display module and bottom plate technology, which is applied to the housing with display/control unit, electrical equipment housing/cabinets/drawers, instruments, etc., to avoid screw corrosion and installation errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

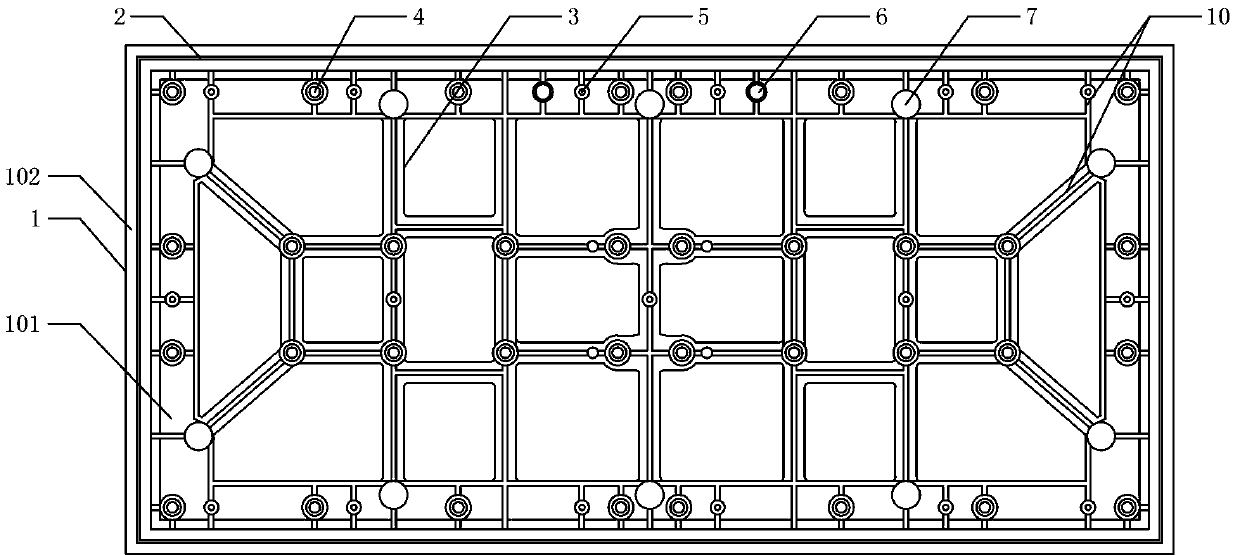

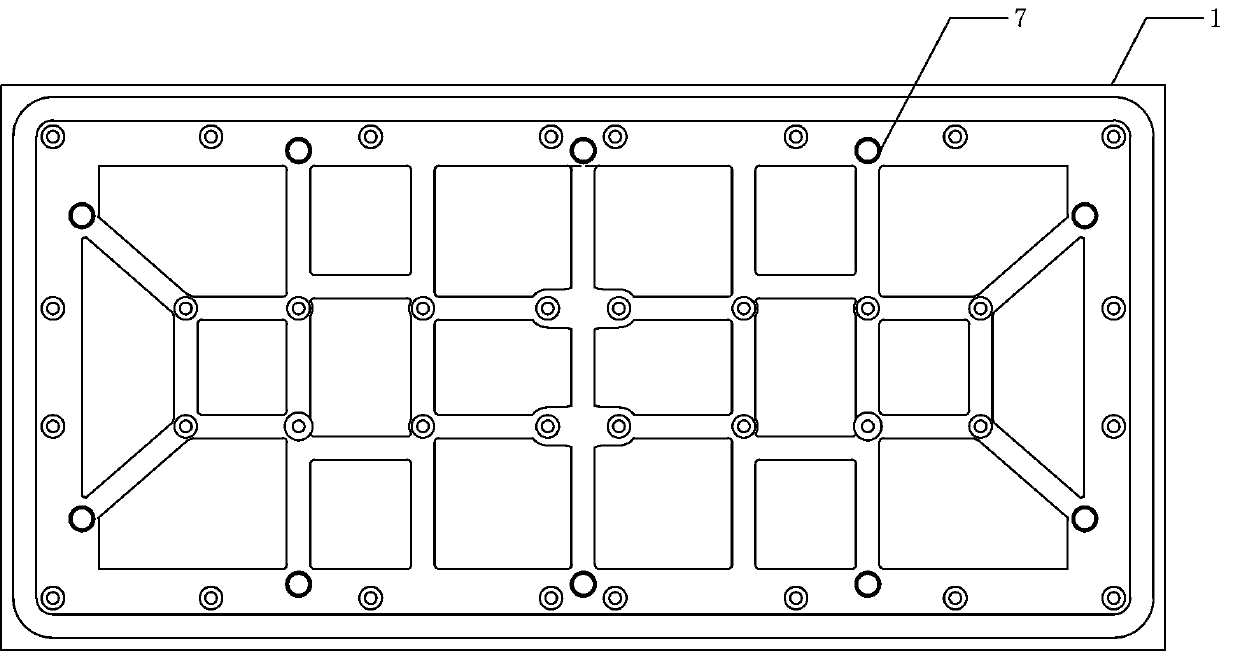

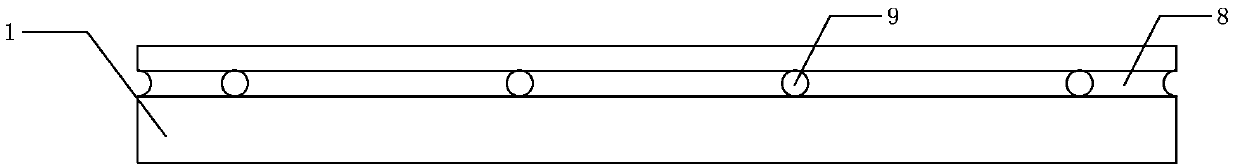

[0020] like Figure 1-4 Among them, a display module bottom case includes a main frame 1, the main frame 1 is a rectangular frame structure composed of a bottom plate 101 and a side plate 102, and a plurality of criss-cross reinforcement plates 3 are arranged inside the main frame 1 , the reinforcing plate 3 and the bottom plate 101 of the main frame 1 are provided with a plurality of hot-melt holes 4 and positioning columns 5 .

[0021] In a preferred solution, a positioning step 2 is provided on the upper edge of the side plate 102 of the main frame 1 .

[0022] In a preferred solution, reinforcing ribs 10 are provided on the top surface of the reinforcing plate 3 .

[0023] In a preferred solution, the hot-melt hole 4 and the positioning column 5 are provided with reinforcing ribs 10 .

[0024] In a preferred solution, the bottom plate 101 on one side of the main frame 1 is provided with a fool-proof hole 6, and the fool-proof hole 6 adopts a cylindrical structure with ho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com