Intelligent logistics system

A technology of intelligent logistics and subsystems, applied in the field of logistics systems, can solve problems such as low shipping efficiency, time-consuming and laborious, and enterprise losses, and achieve the effect of intelligent enterprise management and improved management efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The following are specific examples of the present invention to further describe the technical solutions of the present invention, but the present invention is not limited to these examples.

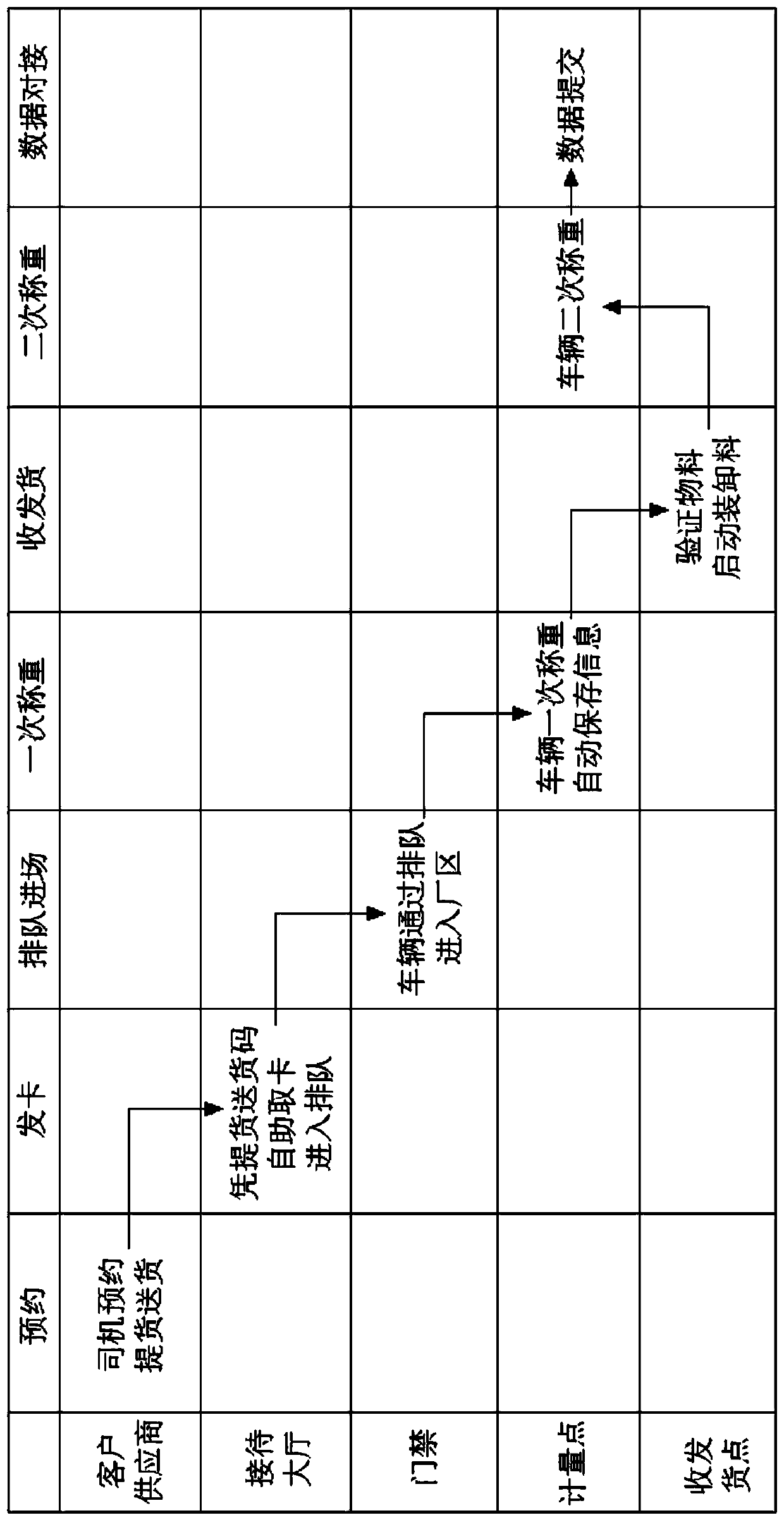

[0017] Such as figure 1 As shown, an intelligent logistics system includes an appointment registration platform, a self-service card sending and receiving system, a queuing system, a bagging confirmation system, an unattended intelligent weighing system for truck scales, a handheld confirmation system and a remote centralized measurement system. Make a self-booking appointment through the appointment registration platform, and the appointment registration platform will issue a pick-up and delivery code, and the driver will pick up the card in the self-service card issuance system based on the pick-up and delivery code, and the vehicle will enter the queue. The access control enters the factory area, the vehicle is automatically weighed for the first time, and the information is sa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com