Surface shape tolerance analysis method for free-form surface imaging system

A surface error and surface technology, which is applied in the field of surface tolerance analysis of free-form surface imaging systems, can solve problems such as the difficulty of surface processing without considering the surface shape, and achieve the effect of flexible use and accurate surface shape.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0051] The present invention will be described in detail below with reference to the accompanying drawings and embodiments.

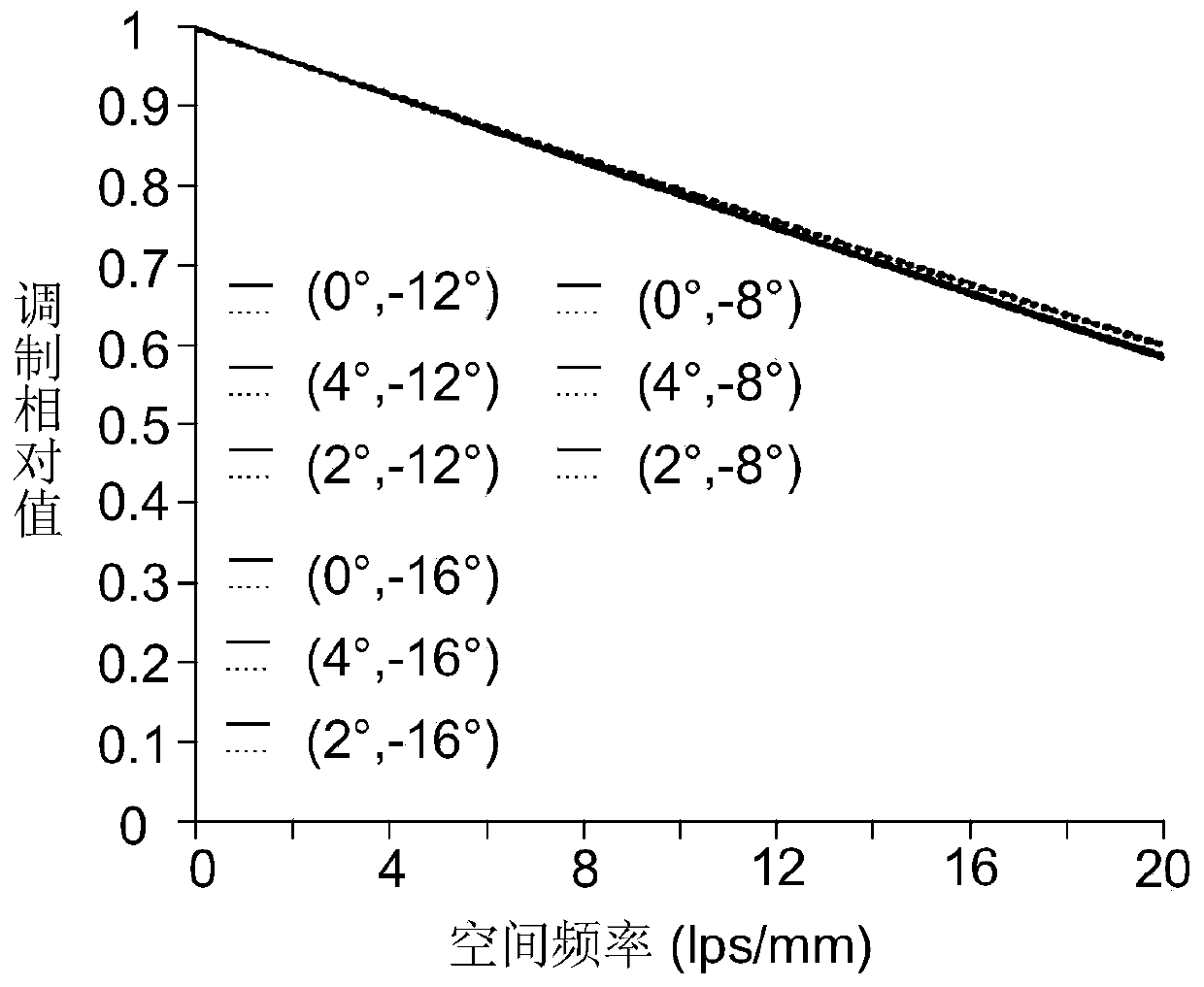

[0052] The present invention provides a surface tolerance analysis method for a free-form surface imaging system, which is used to analyze the surface tolerance of a free-form surface in an optical imaging system. The process of the method is as follows: figure 1 shown, including the following steps:

[0053] S1. Set the maximum acceptable tolerance value.

[0054] S2. Divide a uniform mesh on the surface to be analyzed. After that, it also includes: obtaining the coordinate value and gradient modulus value of the grid point on the surface to be analyzed;

[0055] The coordinate value of the grid point takes the horizontal and vertical directions of the uniform grid as the x and y coordinate axes respectively. The origin can be randomly selected in the uniform grid, for example, a grid point in the lower left corner can be selected as the origin.

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com