Multi-stage pipeline type hysteresis heat effect heating power generation method and generator

A thermal effect, pipeline-type technology, applied in the field of multi-stage pipeline-type hysteresis thermal effect heat generation and generator, can solve the problem of high electric power requirements, and achieve the effect of safe and fast cascade heating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0077] The multi-stage pipe-type hysteresis thermal effect heat generator of this embodiment includes three-stage heating pipe assemblies.

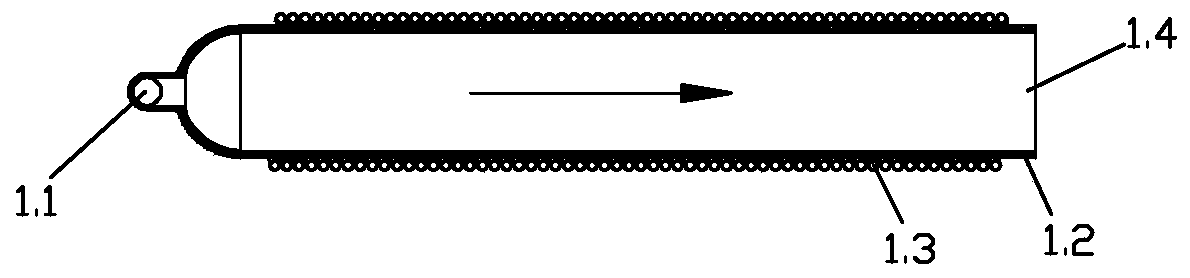

[0078] Such as figure 1 As shown, the heating tube assembly of this embodiment includes a first heating tube 1.2 and a first coil 1.3 sleeved on the first heating tube 1.2, the left end of the first heating tube 1.2 is provided with an inlet 1.1, and the right end is provided with an outlet 1.4, as shown in the figure The direction of the arrow indicates the direction of water flow. In this embodiment, the outer surface of the first heating tube 1.2 is provided with a magnetically sensitive metal material layer capable of generating hysteresis thermal effect in a changing magnetic field. When in use, an alternating magnetic field is generated by the first coil 1.3, and a hysteresis thermal effect occurs on the magnetic material layer to generate heat, which is transferred to the water body to be heated therein through the side wall of th...

Embodiment 2

[0082] The multi-stage pipe-type hysteresis thermal effect heat generator of this embodiment also includes three-stage heating pipe assemblies.

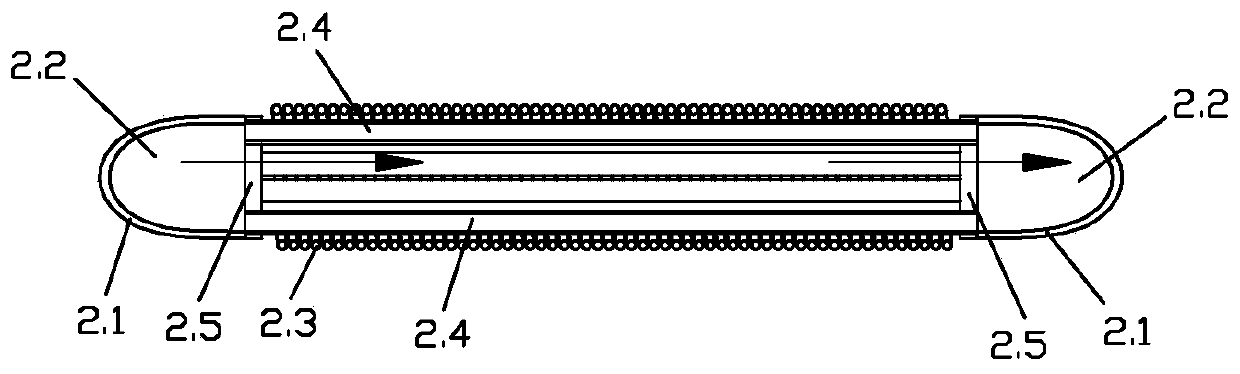

[0083] Such as figure 2 and image 3 As shown, the heating tube assembly of this embodiment includes a second coil 2.3, ten second heating tubes 2.4 and two ends 2.1, the end 2.1 is provided with a water collection chamber 2.2, and ten second heating tubes 2.4 are installed in two Between the ends 2.1, the two ends of the second heating pipe 2.4 communicate with the water collection cavity 2.2 in the ends 2.1 respectively. Specifically, the end 2.1 of this embodiment is an elbow, such as figure 2 As shown, the middle channel of the elbow is the water collection cavity 2.2, and the two ends of the ten second heating pipes 2.4 are respectively connected together through the circular cover plate 2.5, and the ten second heating pipes 2.4 are evenly distributed in the circumferential direction, and the second heating pipes The port o...

Embodiment 3

[0089] The multi-stage pipe-type hysteresis thermal effect heat generator of this embodiment also includes three-stage heating pipe assemblies.

[0090] Such as Figure 4 to Figure 10 As shown, the heating tube assembly 3 of this embodiment includes a third heating tube 3.3, a third coil 3.1, several heating rods 3.4, four guide baffles 3.2, two mounting seats 3.9, an inlet conduit 3.10, and an outlet conduit 3.7 and two sealing heads 3.5. Wherein, the mounting base 3.9 includes an upper clamping base 3.9.1 and a lower clamping base 3.9.2.

[0091] The material of the 3rd heating pipe 3.3 is materials such as high-temperature resistant Teflon or quartz, pottery, corundum, utilizes the water transmission property of materials such as Teflon, quartz and pottery, corundum to reduce the damping of water flow, can adapt to the damping of water flow simultaneously Under the action of a strong magnetic field, the activity of calcium and magnesium ions is enhanced to avoid the forma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com