Integrated hydraulic unit for electro-hydraulic switch machine

A technology of hydraulic unit and switch machine, which is applied in the direction of hydraulic equipment, fluid pressure actuating device, mechanical equipment, etc. used to manipulate turnouts or circuit breakers, and can solve oil leakage, poor reliability, and low degree of modularization, etc. problem, to achieve the effect of reducing the overall size, reducing the size of the whole machine, and improving reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

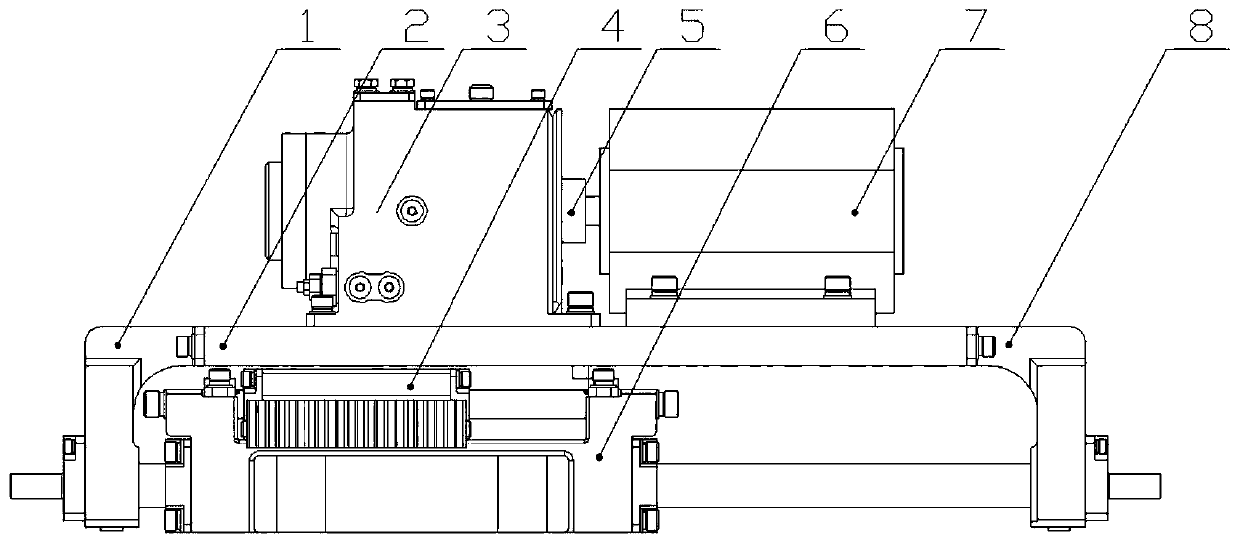

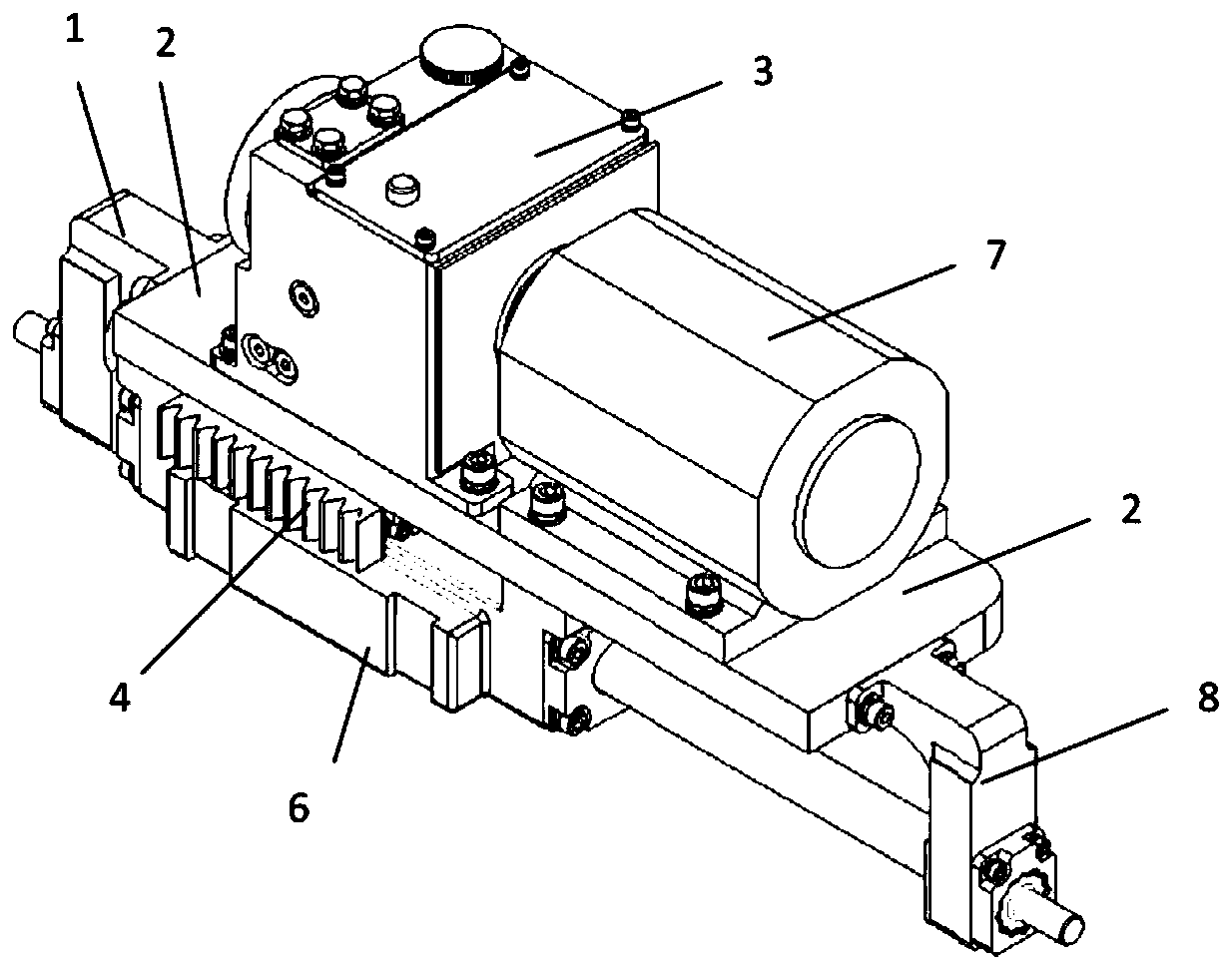

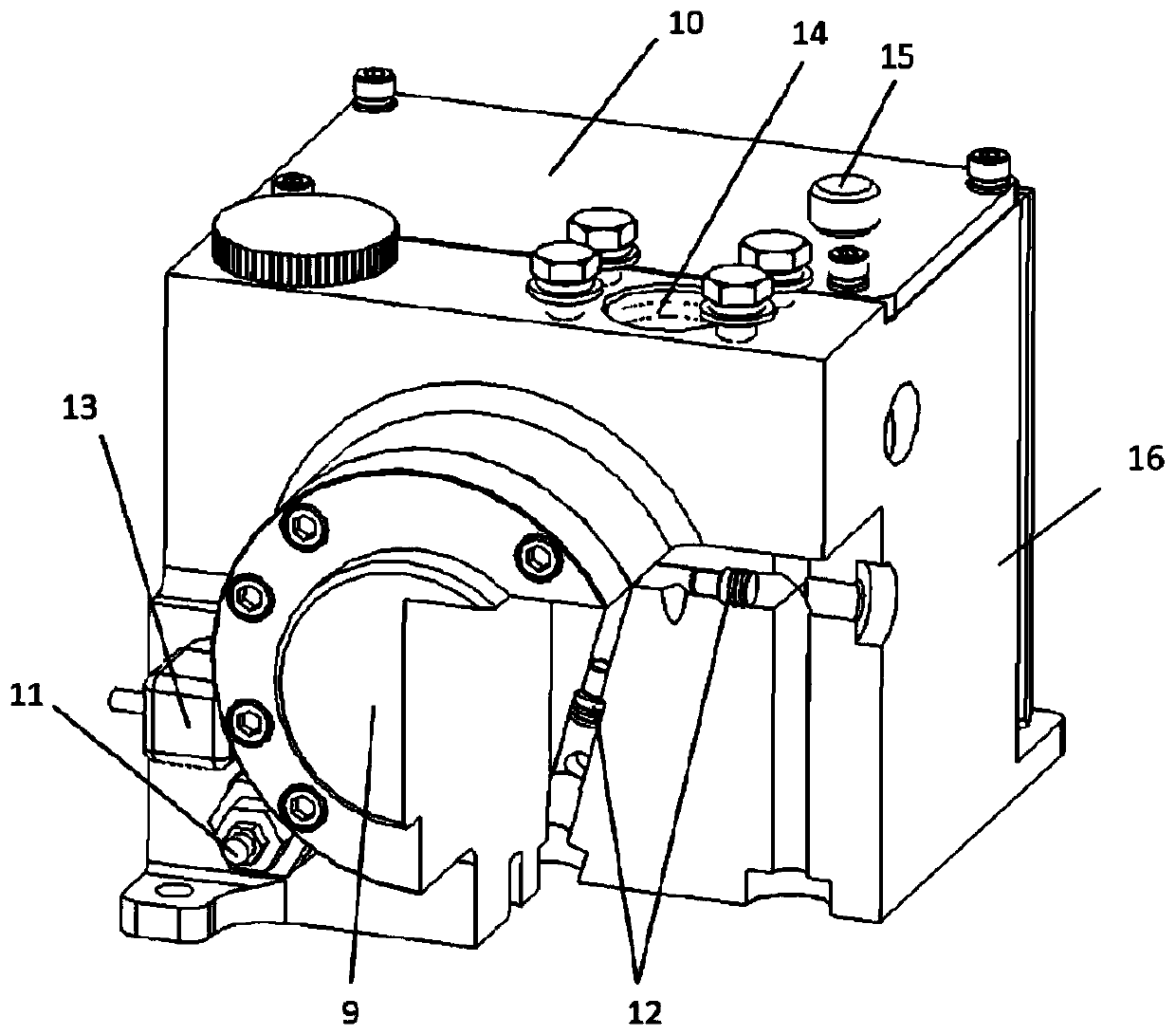

[0026] Such as figure 1 and 2 As shown, an integrated hydraulic unit for an electro-hydraulic switch machine includes a main oil cylinder 6 and an auxiliary oil cylinder 4, and also includes a pump valve oil tank assembly 3, a motor 7, a left oil circuit connecting block 1, a right oil circuit connecting block 8 and The oil circuit is connected to the supporting plate 2; the auxiliary oil cylinder 4 and the main oil cylinder 6 are fixed side by side at the bottom of the oil circuit connecting the supporting plate 2. Specifically, it can be fixed with screws. The auxiliary oil cylinder 4 is fixed on the main oil cylinder 6. Specifically, it can be fixed with screws , wherein the auxiliary oil cylinder 4 and the main oil cylinder 6 are combined into an up and down structure, and the main oil cylinder 6 and the auxiliary oil cylinder 4 are connected in parallel with two cavity oil circuits.

[0027] The two sides of the oil circuit connection support plate 2 are respectively con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com