An integrated system for shallow underground mining, selection and filling of lead-zinc mines

A lead-zinc mine and shallow technology, applied in the mineral processing system, lead-zinc mine mining field, can solve the problem of small scale production capacity, no integrated area for concentrate, no full consideration of the construction difficulty of the chamber group and large investment scale. Convenience of beneficiation equipment transportation and maintenance, operator safety and convenience, safety and environmental protection requirements, etc., to achieve the effect of good production convenience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

[0035] The leading portion of the lead-zinc mine of the present invention is selected, and the preferred embodiment is:

[0036] include:

[0037] Underground mining upgrade and waste stone transport system, underground crushing system, underground selection miners system, filling system and auxiliary production facilities are arranged in shallow formations;

[0038] The lead-to-zinc mine is shallowed in the underground mining system using a mixed well and ramp track, and the underground mining system, the underground mining plant system, the filling system, and the auxiliary production facility are associated with the ground. And has an independent ventilation system and a second security exit;

[0039] The lead-zinc mine is shallowed in the underground mining system, only the slope channel exit and the return air well port are arranged in the ground surface, and the surface export combined with the mine surface landscape design, the surface land is not set, including the NET, th...

specific Embodiment

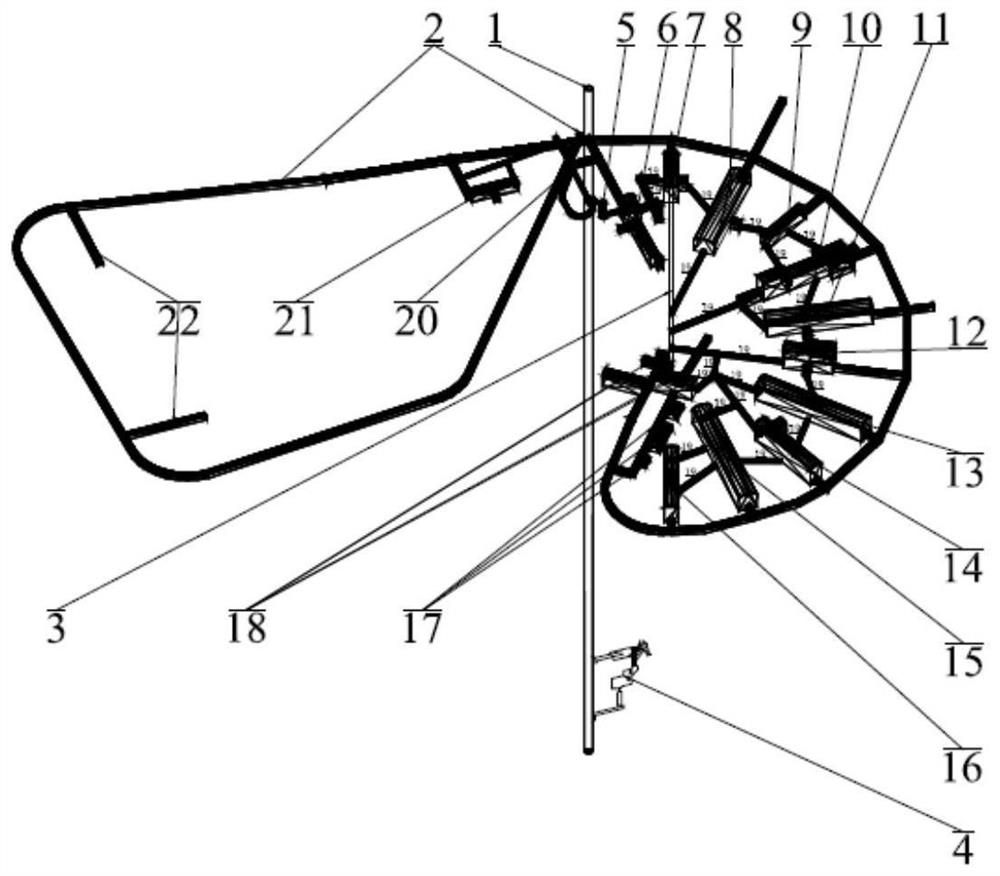

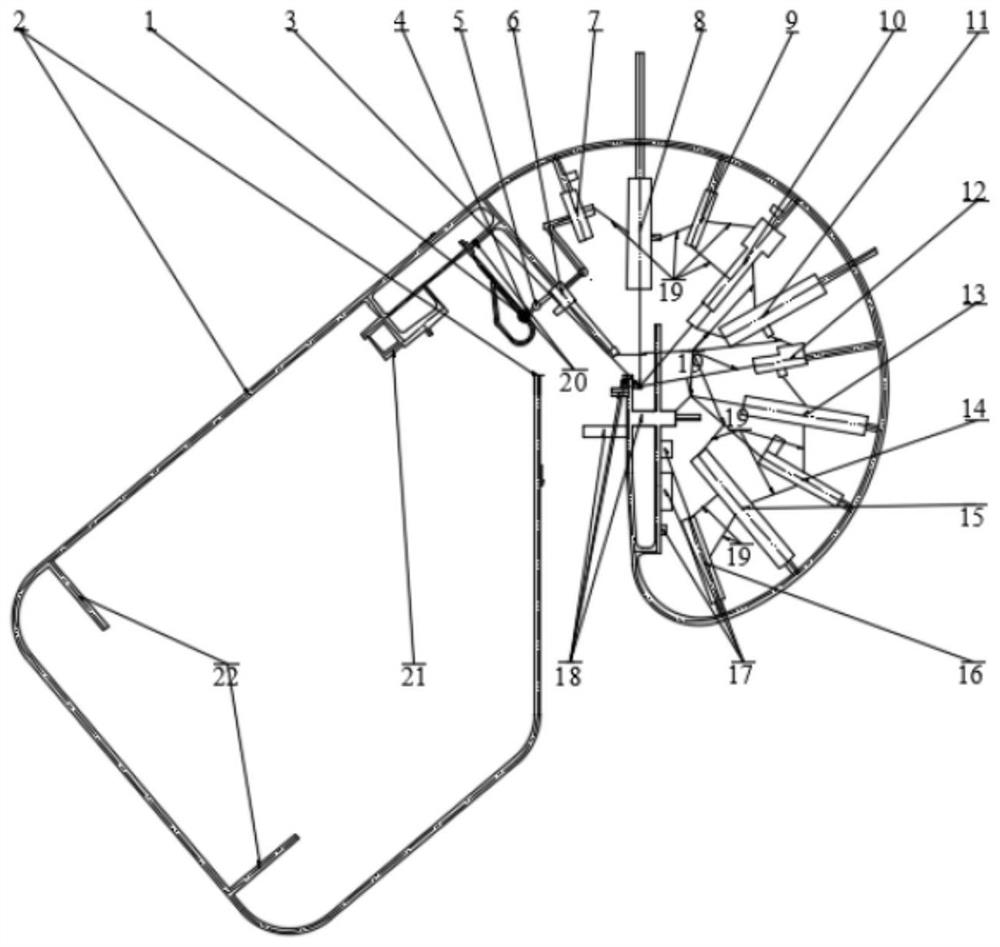

[0047] A shallow partial design of lead-zinc mine, such as figure 1 , figure 2 Down:

[0048] (1) Underground mining improvement, crushing system

[0049] 1) The embodiment system uses a mixed well as a underground mining improvement system, wellhead coordinates Y = 3558134.24; x = 40399019.72; z = + 22m, the well bottom is a high -747m, the net diameter of the well is φ6.5m, and the support, support The thickness is 400 mm. Can cages and buckets in the wellbore, responsible for ore, waste stones, equipment, material transportation and personnel delivery. The mixing well surface facility is a semi-burying well tower, and is in the arrangement of discharge, waste stones and personnel material, and is associated with the ground by ramps. The ladder is within the wellbore as a safe exit.

[0050] 2) Example The system ore primary crash is arranged in the stratum near the bottom of the mixed well, the granular particle size is ≤500mm, the fragmentation particle size reaches ≤200mm, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com