A production process and application of hot-pressed backing paper for pressing copper-clad laminates as a backing layer

A production process and technology of copper clad laminates, applied in the field of pulp and paper making, can solve the problems of not meeting market and production needs, insufficient heat and pressure resistance, high fiber cost, etc., to shorten the heating time, prolong the service life, The effect of increasing physical strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] A production process of hot-pressed backing paper for pressing copper-clad laminates as a backing layer, characterized in that the hot-pressed backing paper for pressing copper-clad boards as a backing layer is made of natural-color softwood pulp, natural-color hardwood pulp and kraft paper The leftovers are fiber raw materials, and short fibers are used for free beating, and the current of the refiner, beating degree and wet weight are controlled, and the final product is 190g / ㎡, thickness 0.300mm, tensile strength 11.8KN / m, air permeability 11.2um / pa·s, folding resistance 17 times, water absorption 127mm / min, tightness controlled at 562kg / m 3 .

[0025] Preferably, it includes the following preparation steps:

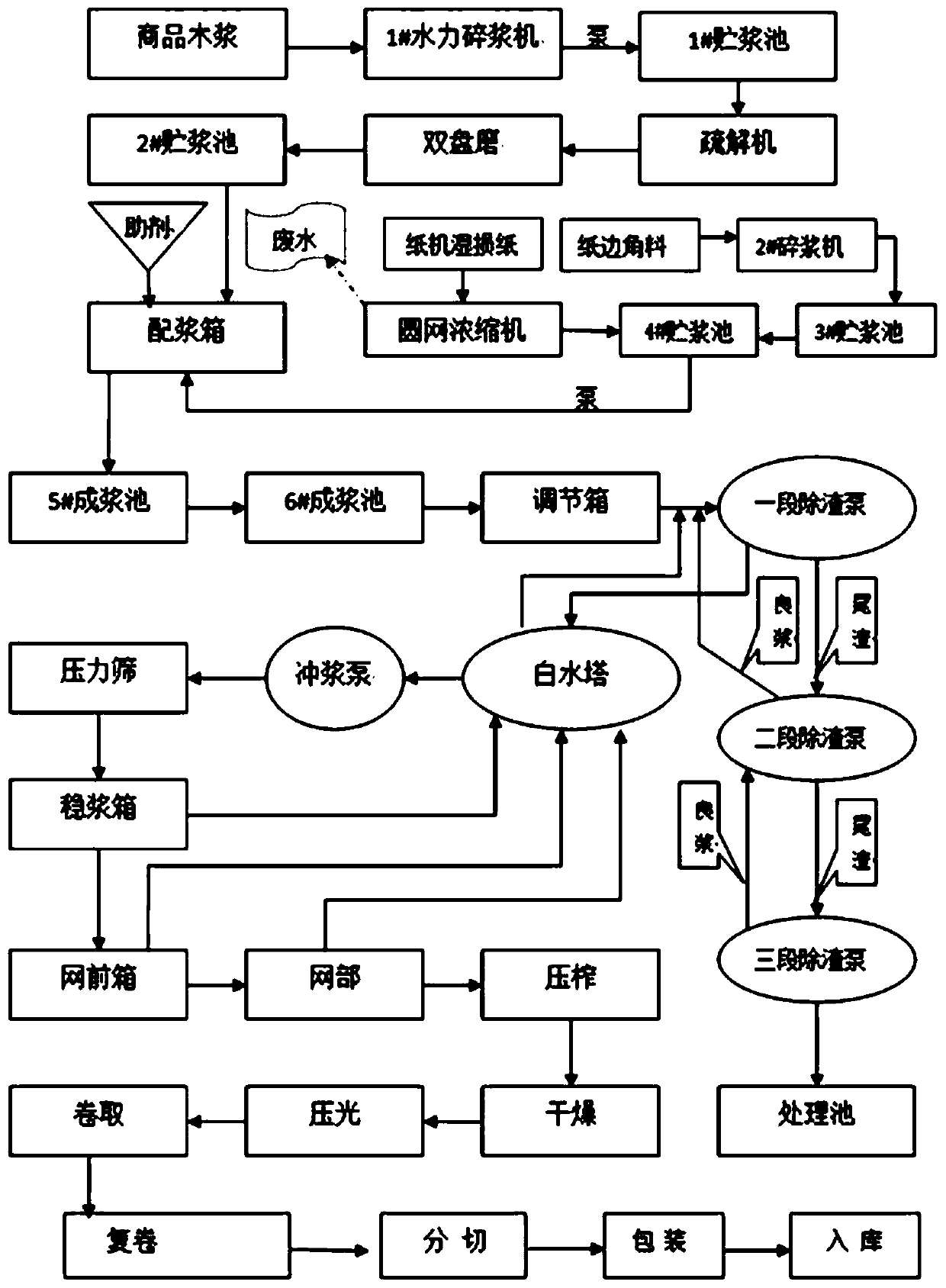

[0026] (1) Wood pulp treatment: Send natural softwood pulp and natural hardwood pulp to 1# hydraulic pulper for mixing and pulping, and then use pumping method to pass through 1# pulp storage tank, deflagging machine and double disc refiner to enter 2# pulp ...

Embodiment 2

[0040] A production process of hot-pressed backing paper for pressing copper-clad laminates as a backing layer, characterized in that the hot-pressed backing paper for pressing copper-clad boards as a backing layer is made of natural-color softwood pulp, natural-color hardwood pulp and kraft paper The leftovers are fiber raw materials, and short fibers are used for free beating, and the current of the refiner, beating degree and wet weight are controlled, and the final product is 192g / ㎡, thickness 0.320mm, tensile strength 12.1KN / m, air permeability 10.9um / pa·s, the folding resistance is 21 times, the water absorption is 119mm / min, and the tightness is controlled at 580kg / m 3 .

[0041] Preferably, it includes the following preparation steps:

[0042] (1) Wood pulp treatment: Send natural softwood pulp and natural hardwood pulp to 1# hydraulic pulper for mixing and pulping, and then use pumping method to pass through 1# pulp storage tank, deflagging machine and double disc r...

Embodiment 3

[0056] A production process of hot-pressed backing paper for pressing copper-clad laminates as a backing layer, characterized in that the hot-pressed backing paper for pressing copper-clad boards as a backing layer is made of natural-color softwood pulp, natural-color hardwood pulp and kraft paper The leftovers are fiber raw materials, and short fibers are used for free beating, the current of the refiner, beating degree and wet weight are controlled, the basis weight is 196g / ㎡, the thickness is 0.340mm, the tensile strength is 11.9KN / m, and the air permeability is 11.4um / pa·s , the folding resistance is 19 times, the water absorption is 106mm / min, and the tightness is controlled at 600kg / m 3 .

[0057] Preferably, it includes the following preparation steps:

[0058] (1) Wood pulp treatment: Send natural softwood pulp and natural hardwood pulp to 1# hydraulic pulper for mixing and pulping, and then use pumping method to pass through 1# pulp storage tank, deflagging machine a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| water absorption | aaaaa | aaaaa |

| water absorption | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com