Base assembly of dye vat system

A dye vat and component technology, applied in the field of machinery, can solve the problems of the uncompact structure of the dye vat system, the cumbersome positioning and connection of the dye vat, etc., and achieve the effects of improving the connection stability, compact structure and improving stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

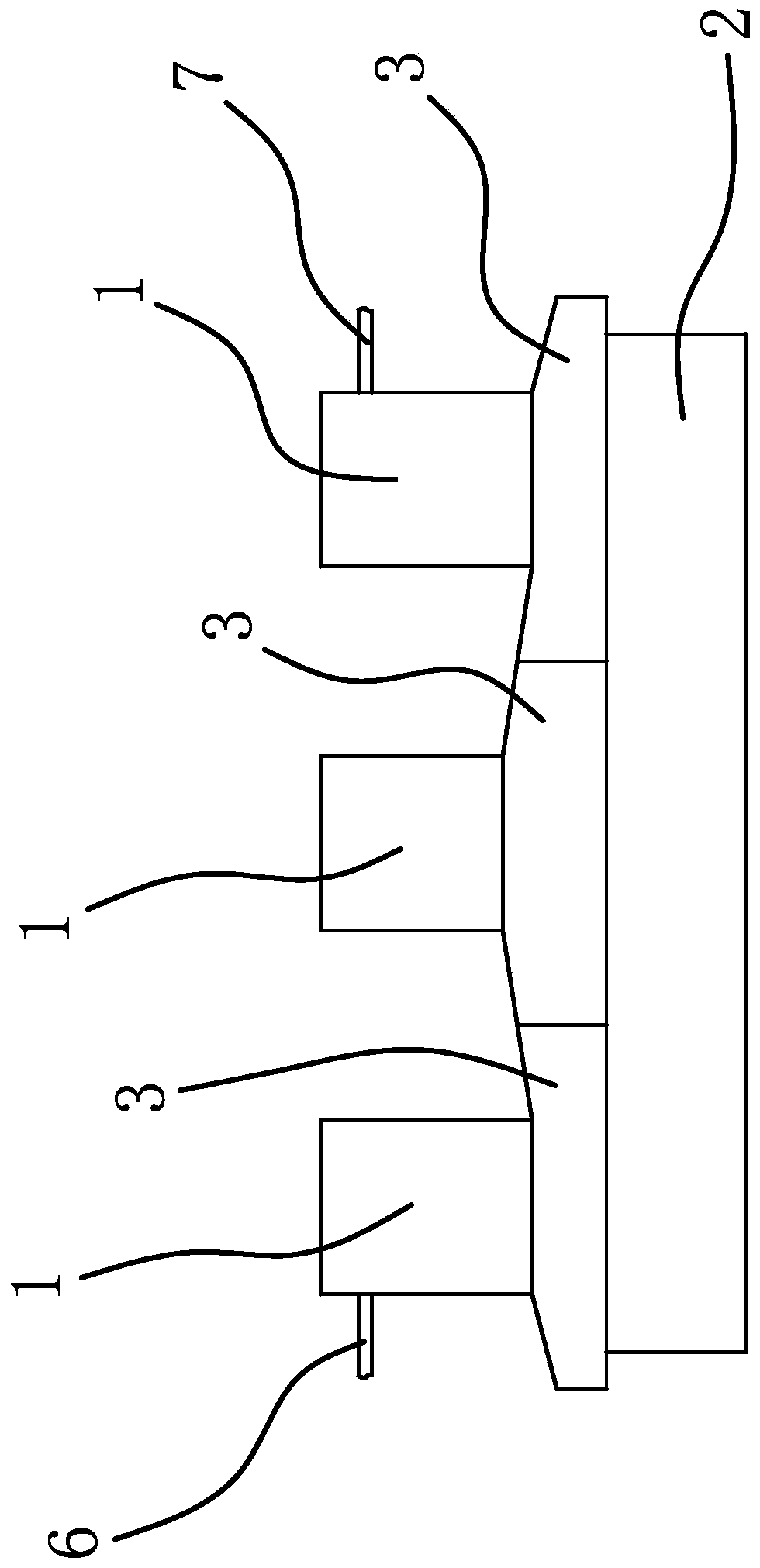

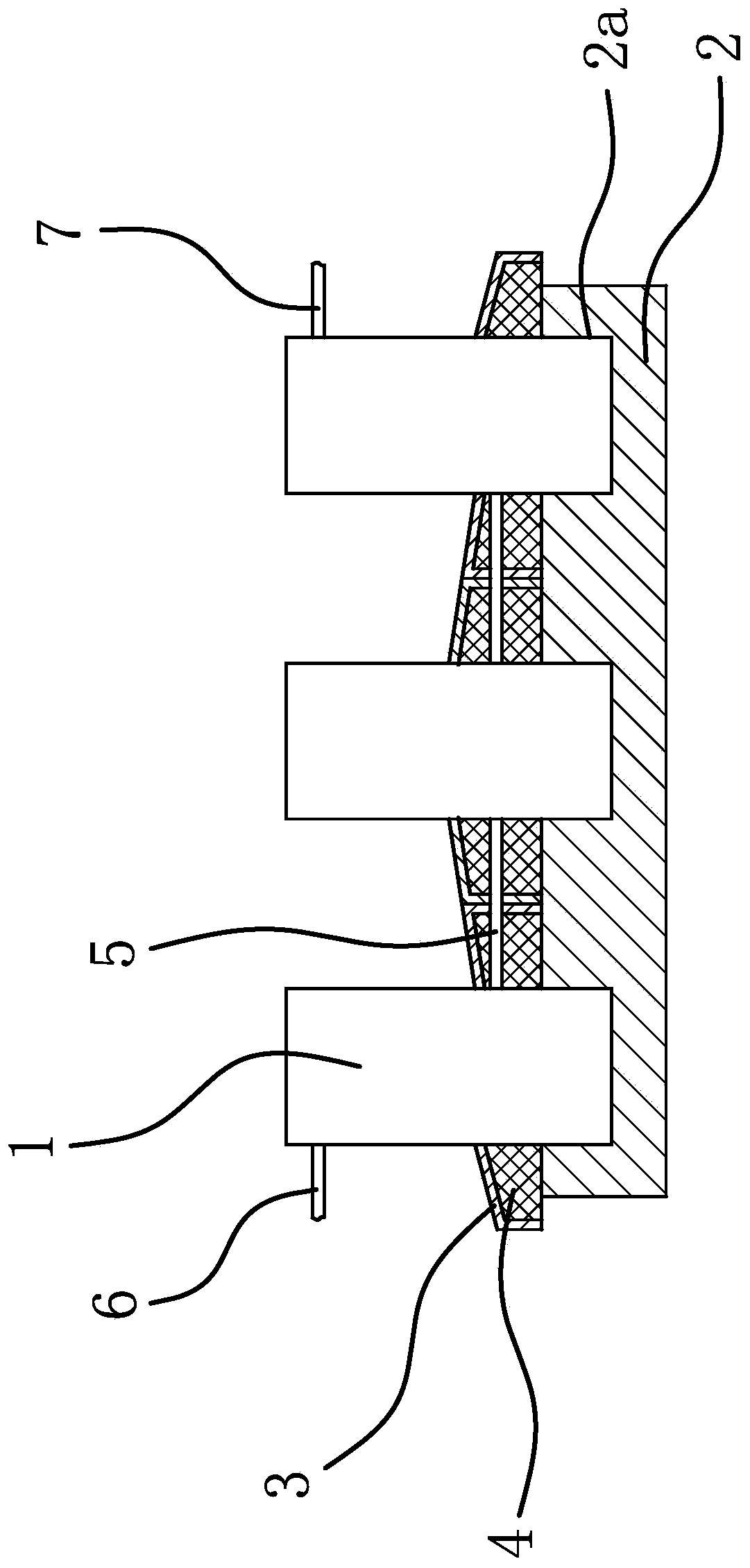

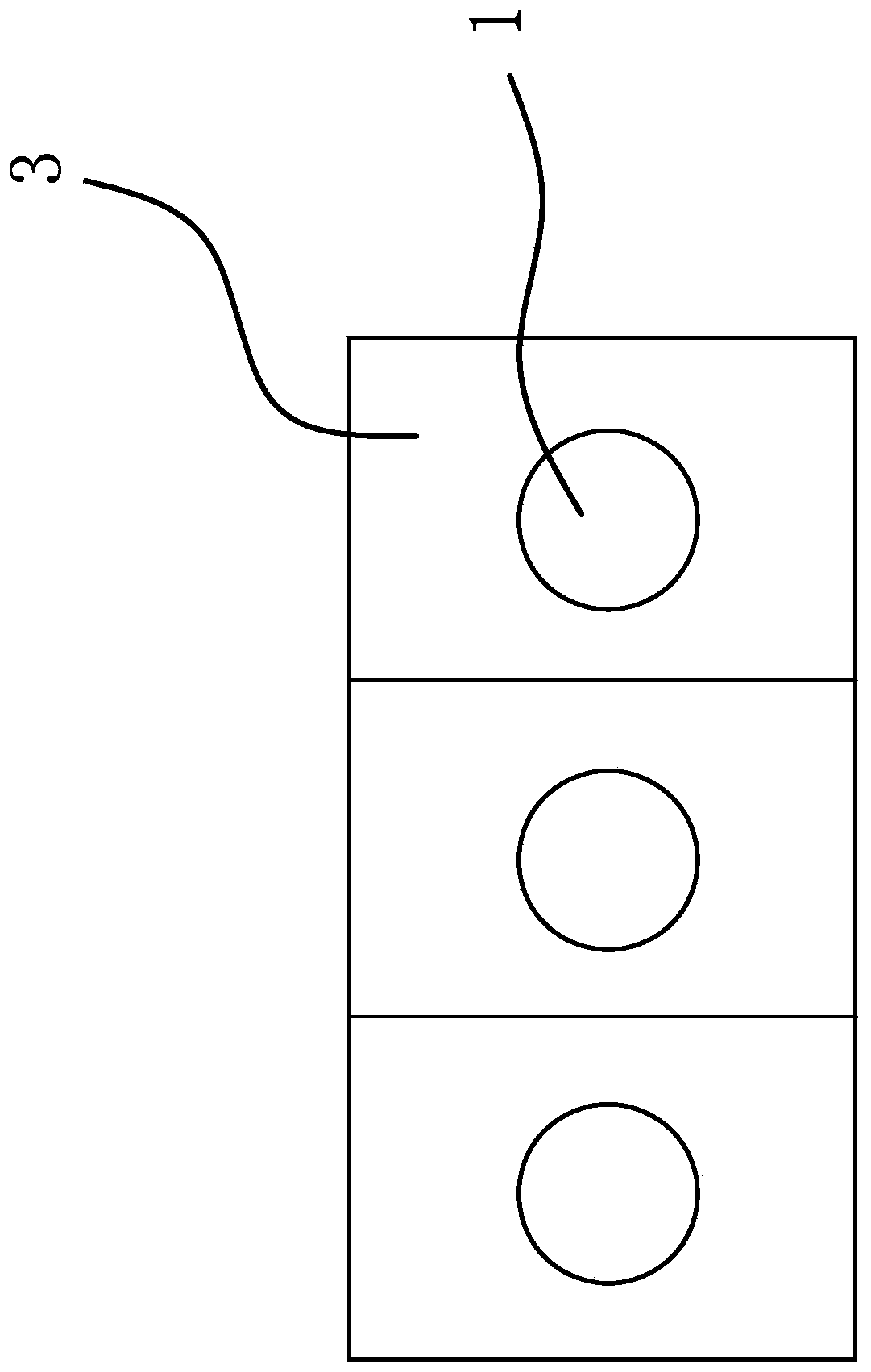

[0023] Such as figure 1 with figure 2 with image 3 As shown, the interior of the dyeing vat is a cavity, and there are several dyeing vats connected in series in sequence.

[0024] The base assembly of the dye vat system includes a base plate 2 and a positioning cover 3. The base plate 2 is in the shape of a long plate. The upper surface of the base plate 2 has a number of concave positioning notches 2a along its length direction. Matching and the lower end of the dyeing vat 1 is connected to the positioning notch 2a, the number of the dyeing vat 1 is the same as the number of the positioning notch 2a, and the two are arranged in one-to-one correspondence. The above-mentioned positioning cover 3 has a through connection hole, and the above-mentioned positioning cover 3 is in one-to-one correspondence The sleeve is placed on the dye vat 1 and the lower end of the positioning cover 3 abuts against the base plate 2, and the side parts of two adjacent positioning covers 3 main...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com