Warp knitting machine with bilaterally-driven guide bar-bed assembly

A double-sided drive, warp knitting machine technology, applied in the field of warp knitting machines, can solve problems such as insufficient stability, and achieve the effects of easy high-speed operation, reduced vibration, and reduced noise pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

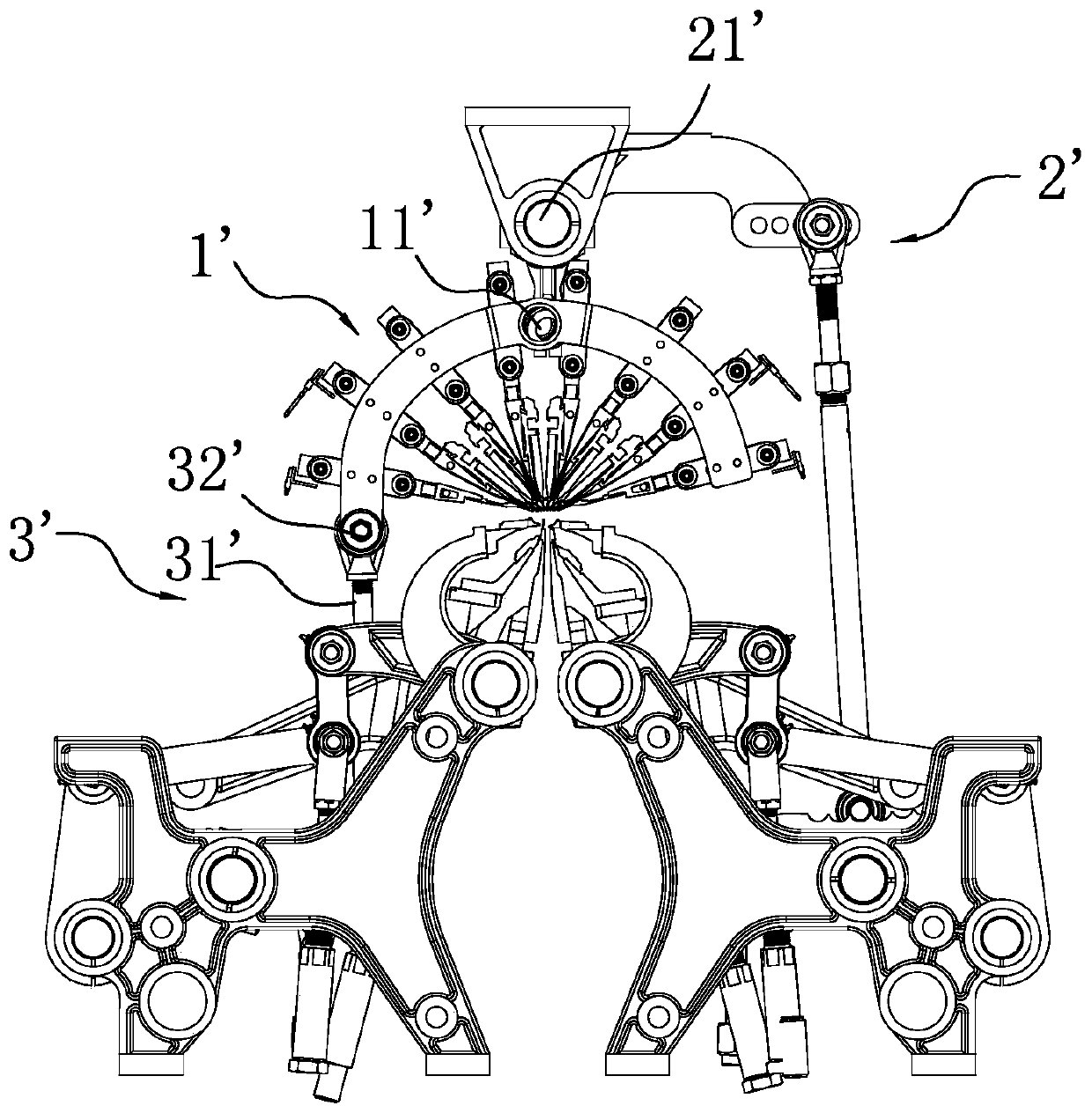

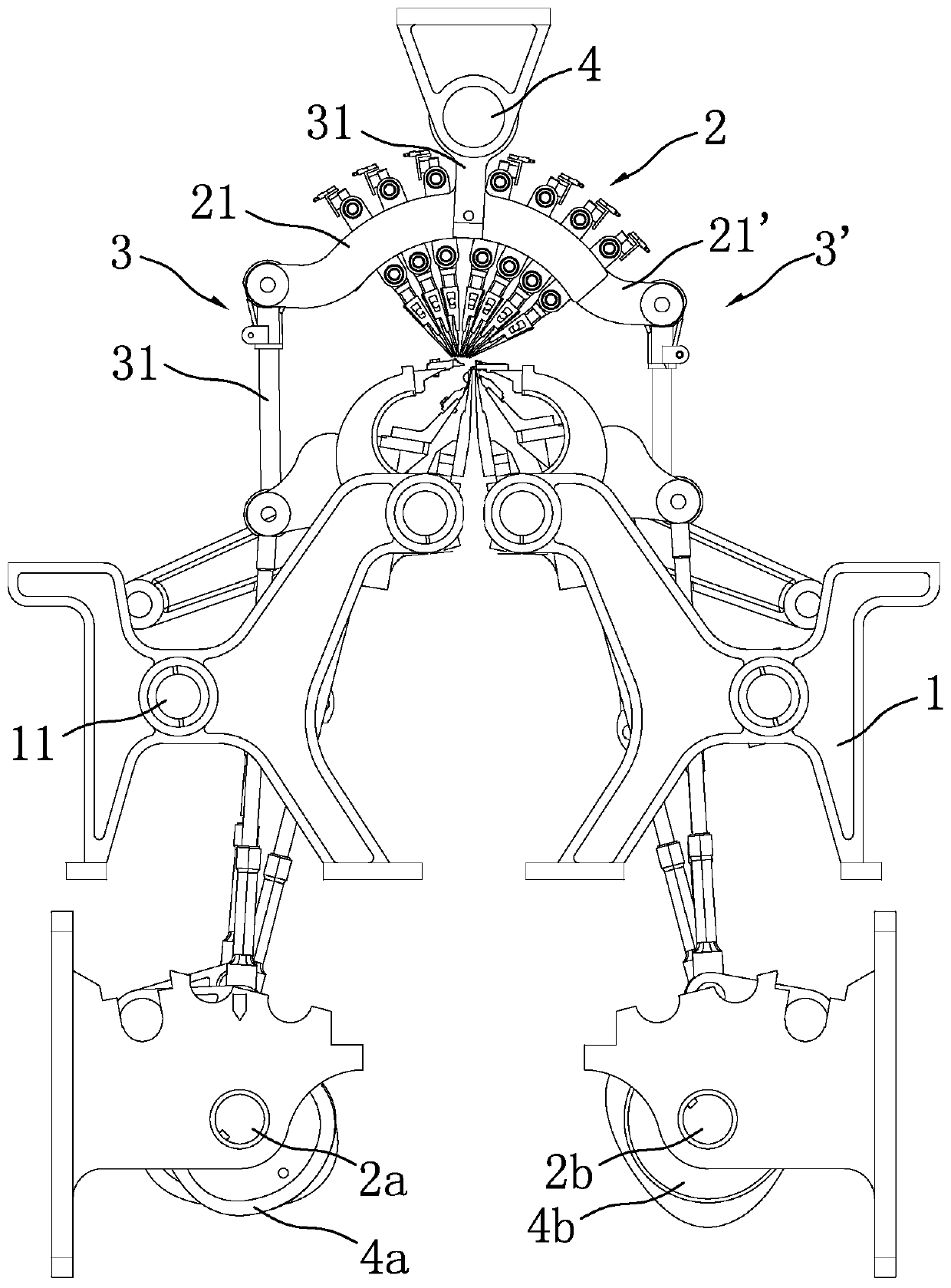

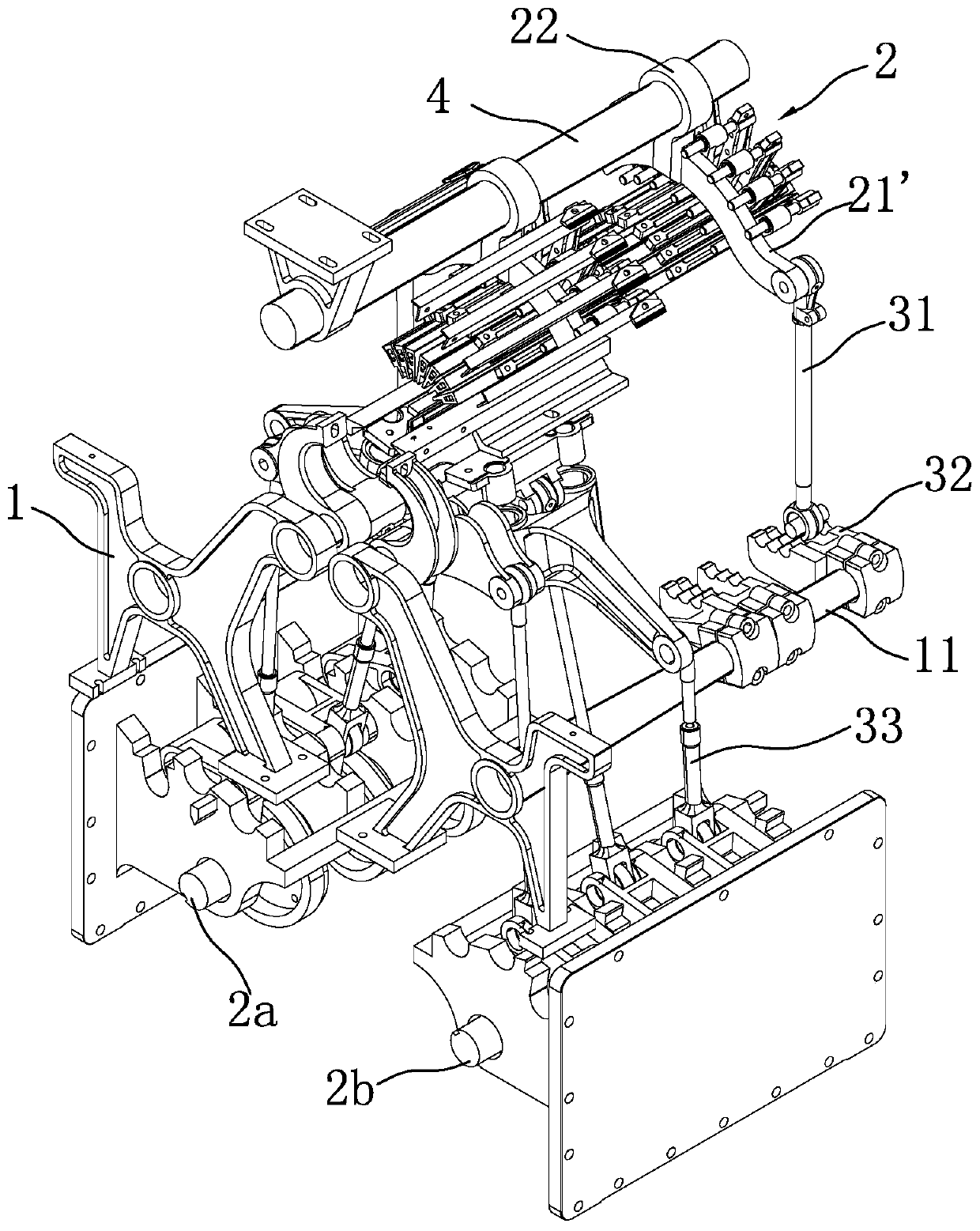

[0031] refer to Figure 2 to Figure 5 , a kind of warp knitting machine driven by both sides of the comb bed assembly, comprising a frame 1 and a comb bed assembly 2 installed on the frame 1, a main shaft one 2a, a main shaft two 2b and a motor one 3a as power, the main shaft One axial end of one 2a is connected to the output end of motor one 3a by transmission, and the main shaft one 2a is provided with three synchronously rotating cams one 4a. Establish connection; the main shaft 2b is provided with 3 cams 4b that rotate synchronously, each of the cams 4b is pivotally connected with the swing arm 21' on the other side of the comb bed assembly 2 through the transmission device 2 3', each of the The first cam 4a and the second cams 4b have the same circumferential profile along the circumferential direction, and the phase difference between the two is 180 degrees. The first main shaft 2a and the second main shaft 2b are synchronized by a synchronous mechanism. A pendulum shaf...

Embodiment 2

[0038] refer to Figure 8 , Compared with Embodiment 1, the end of the swing arm 21, 21' connected to the swing rod 31 in this embodiment is provided with five installation adjustment holes 211, and the swing rod is installed on one of the installation adjustment holes 211. This structure, when needed, can adjust the installation adjustment hole 211 where the swing rod 31 is located, and then realize the adjustment of the swing range structurally. The farther away from the installation adjustment hole of the balance shaft 4, the smaller the swing amplitude.

[0039] The present invention does not make specific statements on the loop forming device, etc. For details, refer to the applicant's prior application CN108642698A.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com