Belt-type conveying device and silo feeding system

A belt conveying and conveying technology, which is applied in the directions of transportation and packaging, conveyor objects, loading/unloading, etc., can solve the problems affecting the service life of the conveying device and the large center of gravity offset, and achieves small length and size, and the center of gravity is offset. The effect of small displacement and easy installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

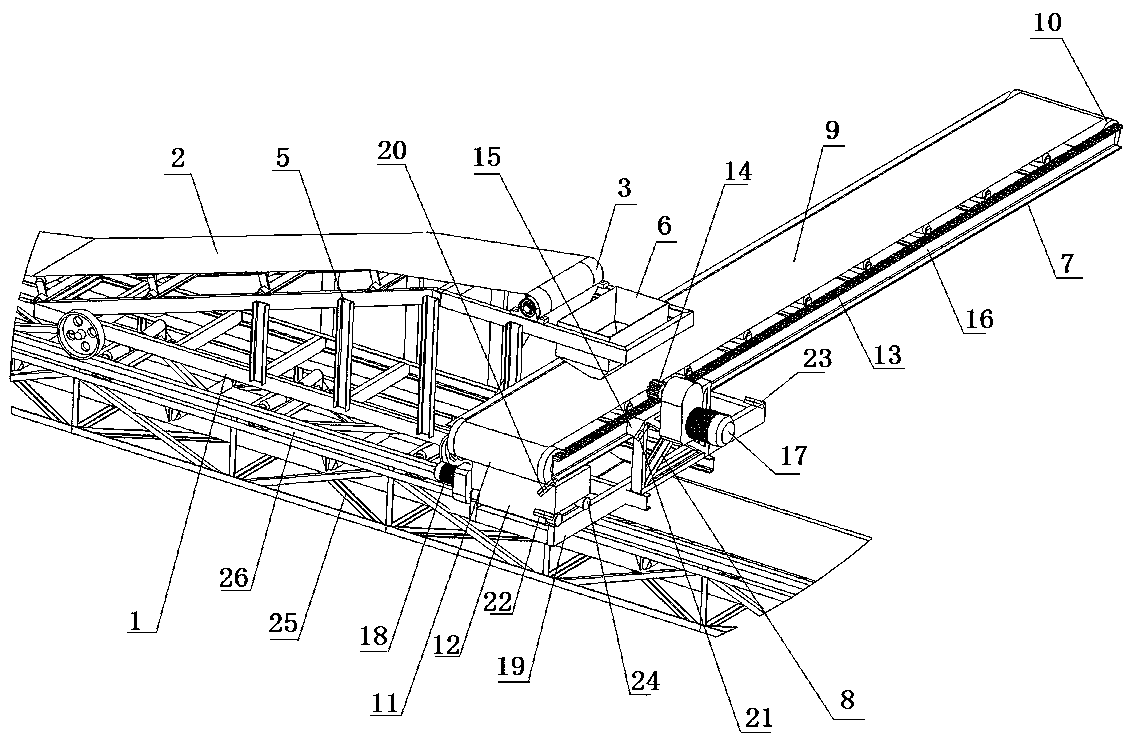

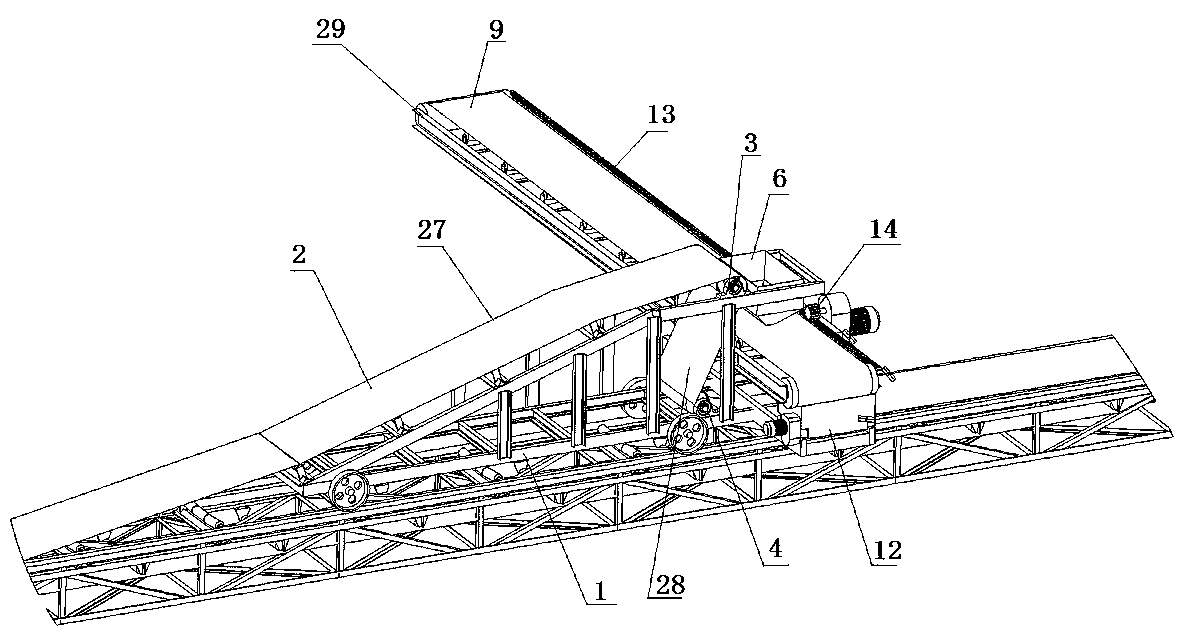

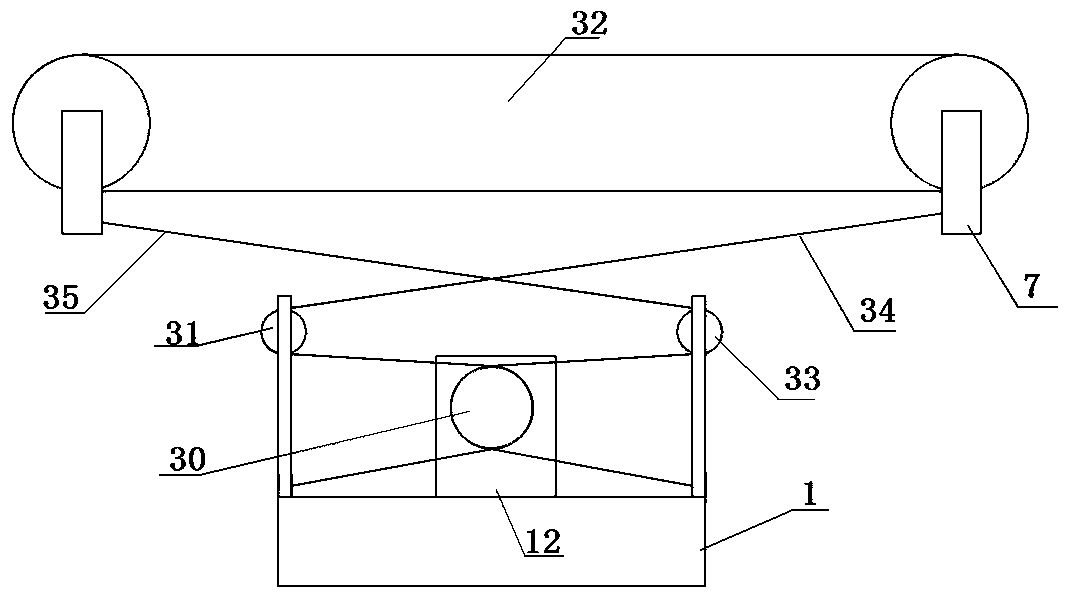

[0059] Such as Figure 1 to Figure 2 As shown, the belt conveying device includes a main conveying mechanism and an auxiliary conveying mechanism, wherein the main conveying mechanism includes a conveying frame 25 for fixing in the silo, and the conveying frame 25 is provided with a main conveying mechanism extending along the front-to-back direction. Track 26, the two ends on the main conveying track 26 are respectively provided with rollers (not shown in the present embodiment, only showing a part of the main conveying track) that are used to transport the main conveying belt 2 of the material, on the main conveying track 10 there are A plurality of supporting rollers arranged at intervals along the extending direction are provided to support and convey the main conveyor belt 2 .

[0060] The main conveying mechanism also includes the mobile chassis 1 that moves back and forth and is assembled on the main conveying track 26. The mobile chassis 1 includes a disc body and a su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com