Vertical type sand making machine graded energy-saving feeding device

A technology of feeding device and sand making machine, which is applied in the direction of solid separation, filter screen, grille, etc., can solve the problems of reduced work rate, waste of manpower, increased workload, etc., so as to reduce workload and work efficiency. High, low workload effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

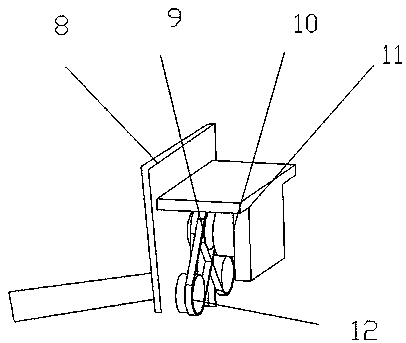

Embodiment 1

[0021] see Figure 1-3 What is disclosed is a grading and energy-saving feeding device for a vertical sand making machine, comprising a base 1, a conveyor belt 2 and a screening member 5. The base 1 is provided with a conveyor belt 2, and one end of the conveyor belt 2 is connected with a driving device, and the conveyor belt 2 rotates through the driving device, thereby completing the transportation of raw materials. The conveyor belt 2 is provided with several rubber strips 3, which increase the friction of the conveyor belt 2, make the transmission smoother, and prevent the raw material from slipping on the conveyor belt 2. Below the other end of the conveyor belt 2, a support plate 8 is fixedly arranged on the upper surface of the base 1, and a sieve 5 is arranged on the support plate 8, and the raw materials conveyed by the conveyor belt 2 fall on the sieve 5 for grading. The bottom of the conveyor belt 2 is provided with a collecting tank 4, and the raw materials convey...

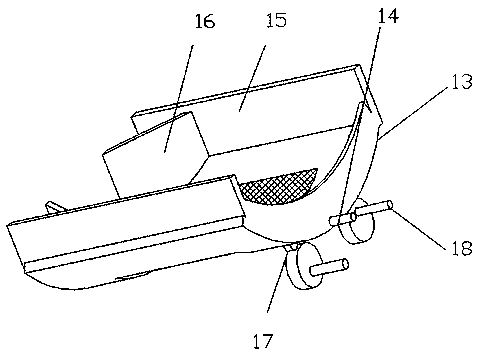

Embodiment 2

[0025] On the basis of Embodiment 1, the bottom of the curved sieve plate 13 is rotated with two rotating wheels 17, and the rotating wheels 17 are in contact with the top of the eccentric wheel 18. The setting of the rotating wheels 17 reduces the contact between the eccentric wheel 18 and the curved screen The friction between the plates 13 makes the arc-shaped sieve plate 13 swing more smoothly.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com