AI-based magnetic core product defect detection system and method

A product defect detection system technology, applied in the field of artificial intelligence, to achieve the effect of simple transplantation, fast detection speed, and speed improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described in detail below in conjunction with the accompanying drawings, and specific implementation methods will be given.

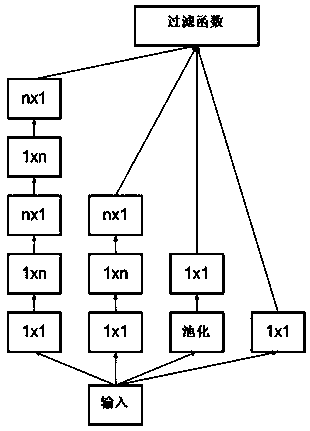

[0029] Such as figure 1 As shown, the AI-based magnetic core product defect detection method of the present invention adopts a system including a camera image acquisition and preprocessing module, a pre-trained SSD model based on Inception_v3, a comprehensive screening module and a model operation scheduling module. The image acquired by the front-end camera is transmitted to the camera image acquisition and preprocessing module through the network, and the image preprocessed by the camera image acquisition and preprocessing module is performed by the SSD model based on Inception_v3 pre-trained in the model operation scheduling module selection subprocess Detect and identify, and feed back the results to the comprehensive screening module to further screen with the results of cluster analysis performed in adv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com