Method for making internal cracks in rock samples and quantitative evaluation of grouting effect

A technology for quantitative evaluation and grouting effect, which is applied in the field of rock mechanics and engineering, can solve the problems of large discreteness, difficult test, and inability to make internal cracks, etc., and achieve high repeatability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] The specific implementation of the method for making internal cracks in rock samples and quantitatively evaluating the grouting effect involved in the present invention will be described in detail below in conjunction with the accompanying drawings.

[0047]

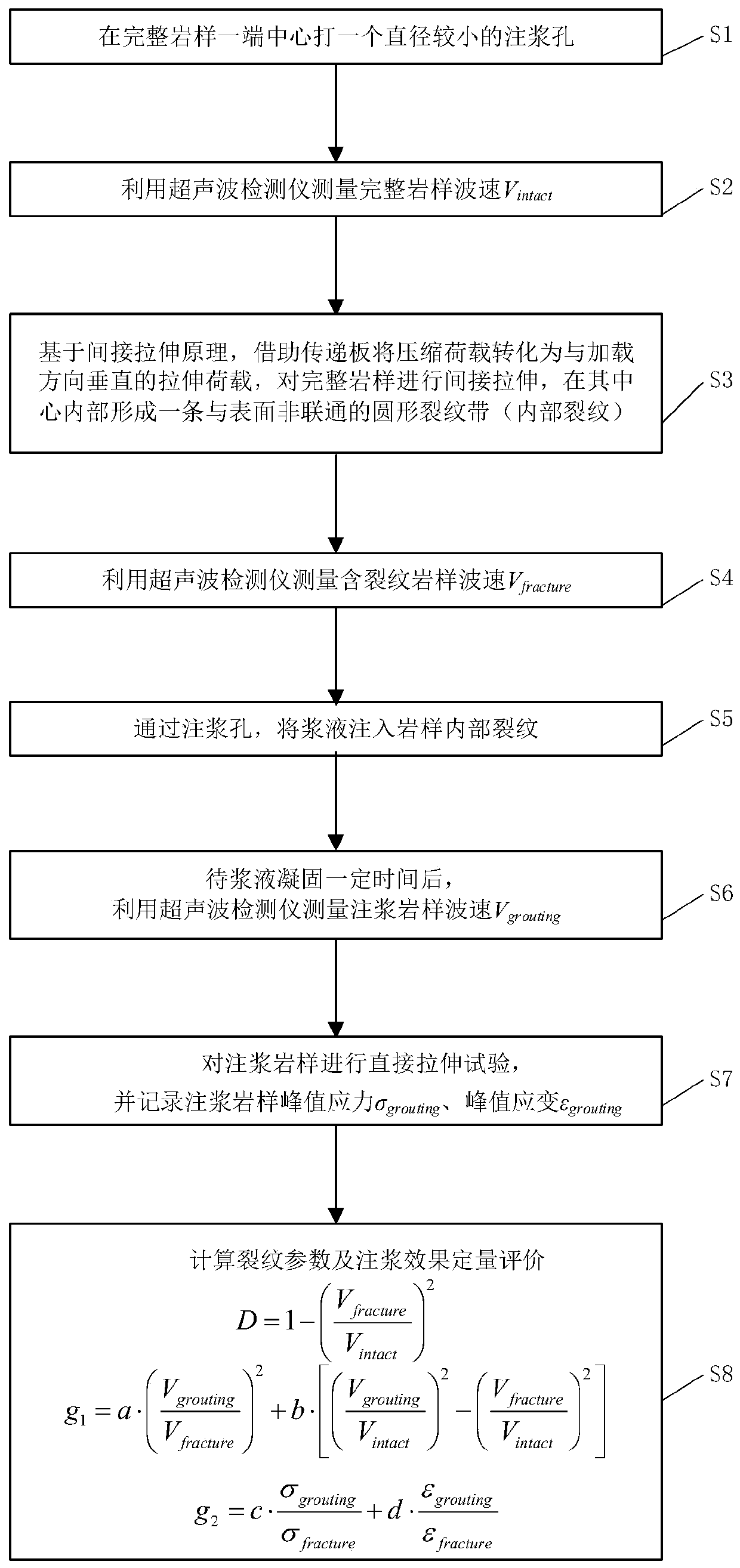

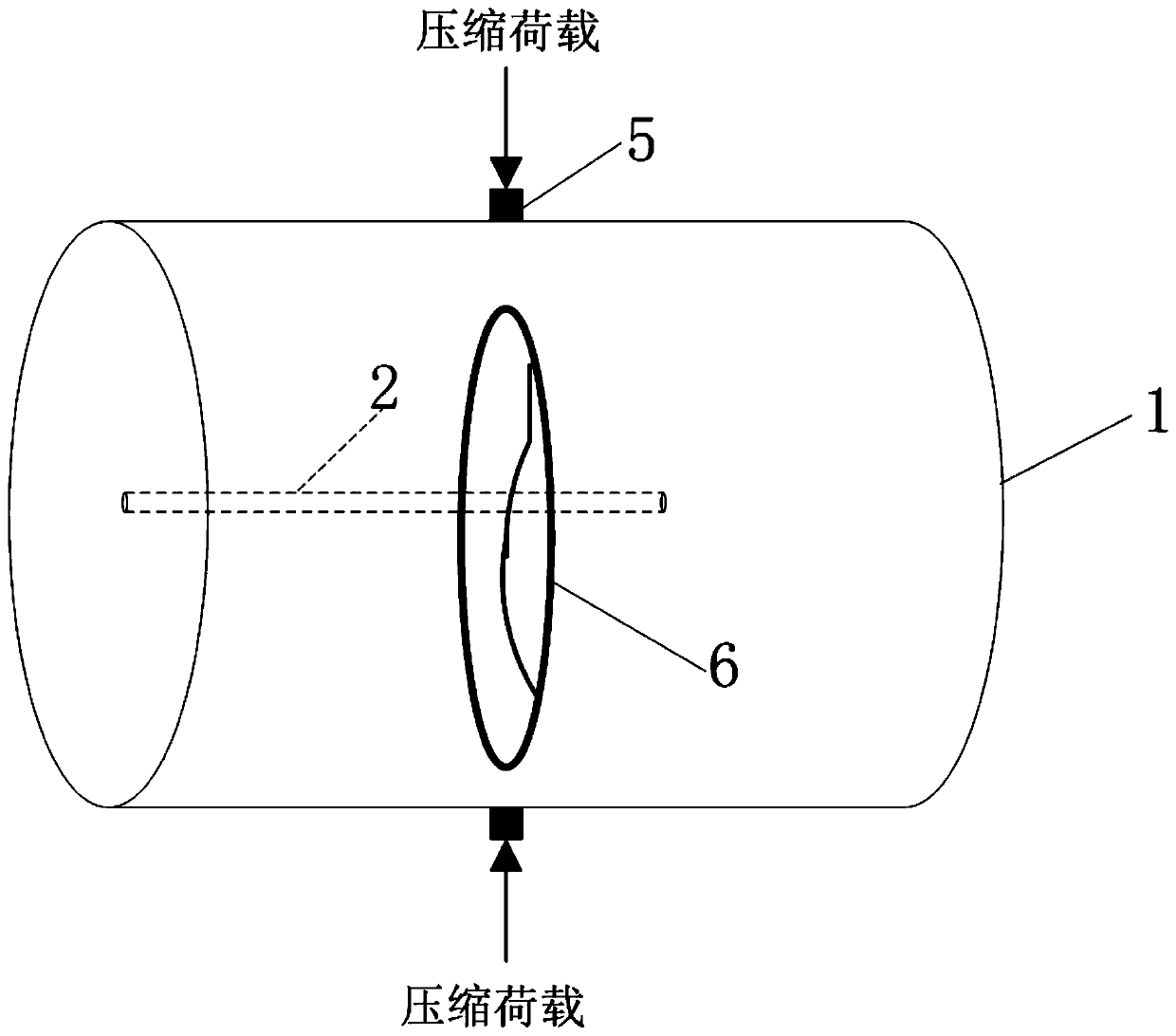

[0048] like Figures 1 to 5 As shown, the method for making internal cracks in the rock sample and quantitatively evaluating the grouting effect provided by this embodiment specifically includes the following steps:

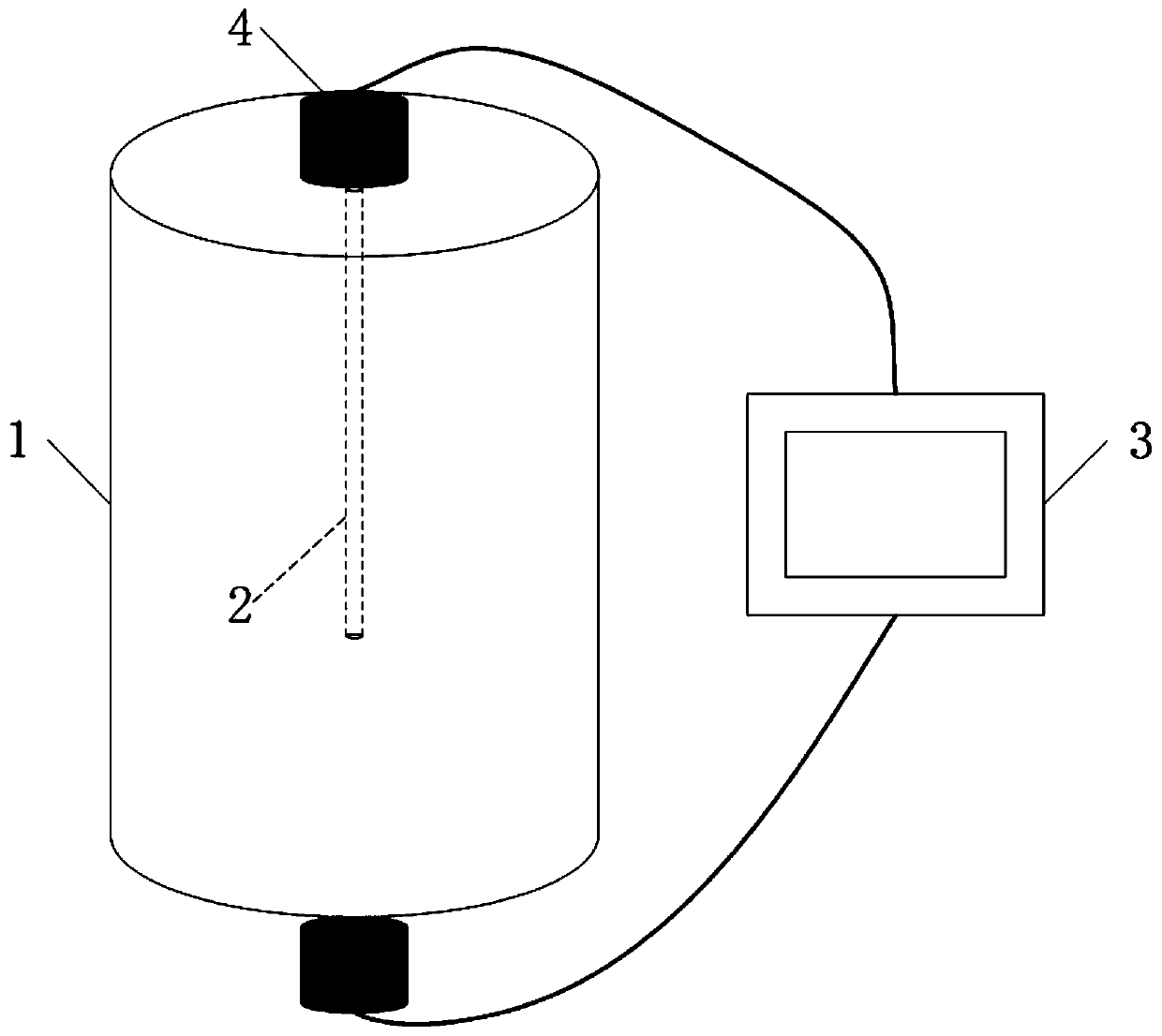

[0049]Step 1. Drill a grouting hole 2 with a smaller diameter at the center of the upper end (in the radial direction) of the complete rock sample 1, the grouting hole 2 is a non-through hole, and the hole depth is 3 / 4 of the height of the rock sample 1 .

[0050] Step 2. If figure 2 As shown, the two probes 4 of the ultrasonic detector 3 are respectively placed on the two ends of the rock sample 1, and the ultrasonic detector 3 is used to measure the wave velocity V of the rock sample 1 after d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com