Heat pump drying equipment, and dehumidifying control method and dehumidifying control device thereof

A heat pump drying and equipment technology, applied in lighting and heating equipment, drying, heat pump and other directions, can solve the problems of poor dehumidification reliability, waste of energy, unfavorable energy conservation and environmental protection, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

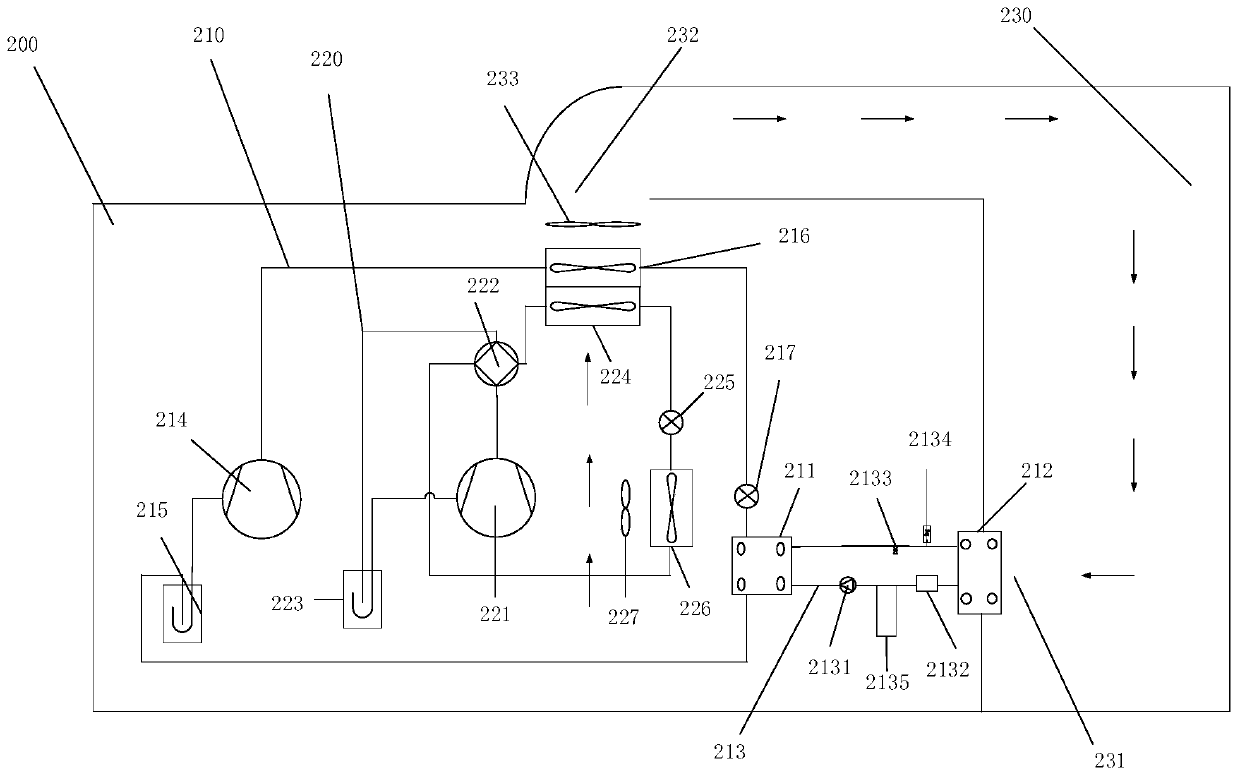

[0063] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

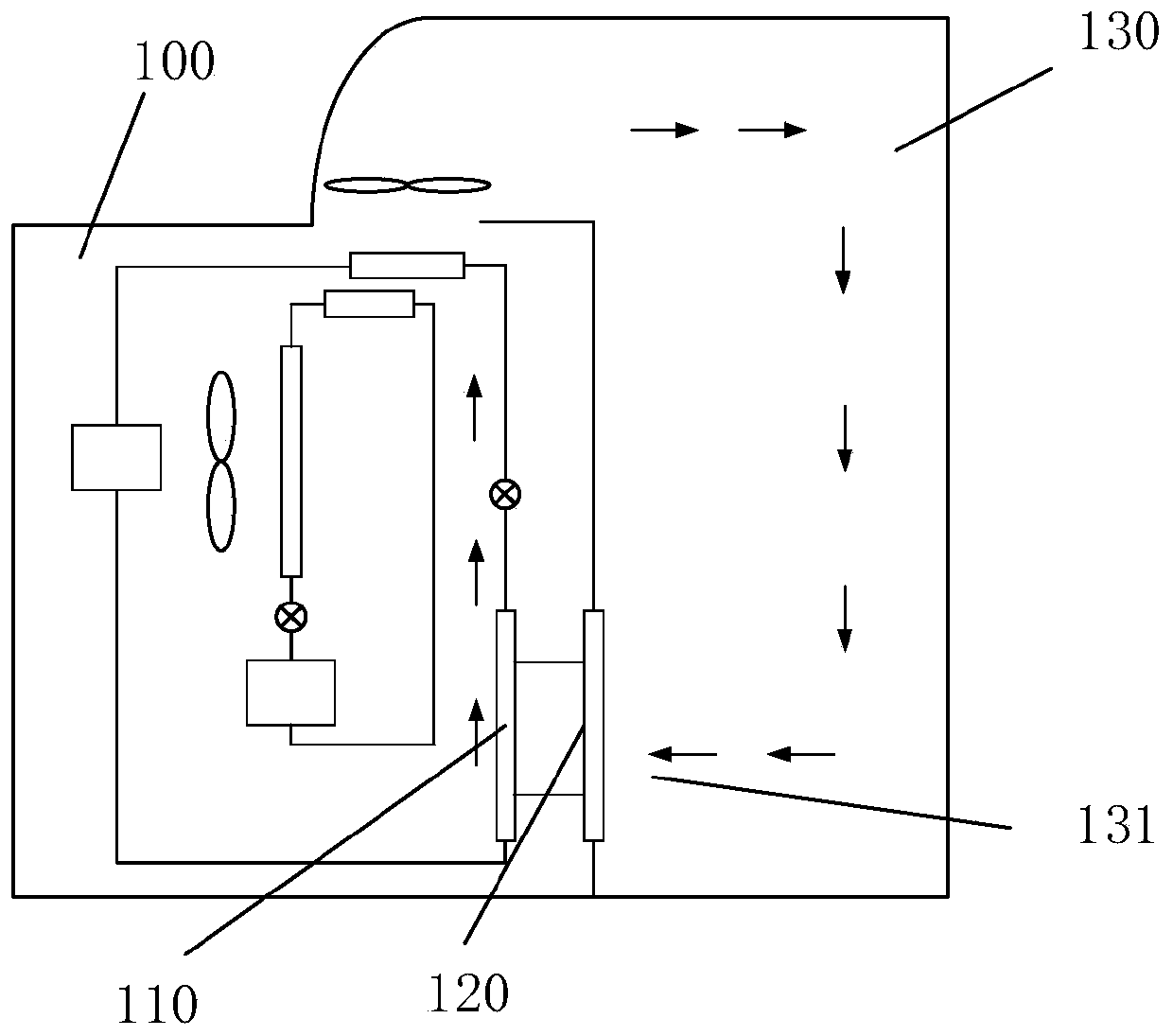

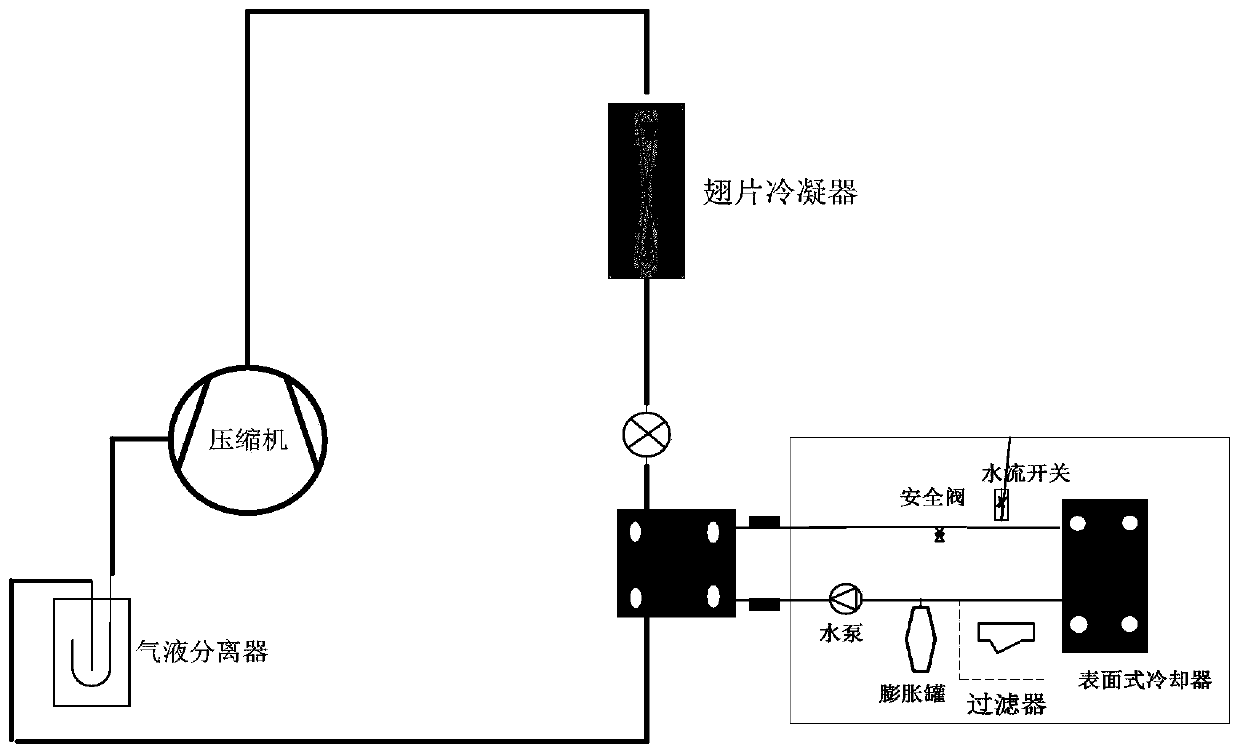

[0064] refer to figure 1 , figure 2 , it should be noted that the arrows in the figure represent the direction of air flow when the equipment is working. The embodiment of the present invention provides a heat pump drying equipment 100, including:

[0065] first evaporator 110;

[0066] A dehumidification module 120 connected to the first evaporator 110;

[0067] The dehumidification module 120 is used for condensing and dehumidifying the air flowing out through the air return port 131 of the drying room 130 .

[0068] A heat pump drying device provided in an embodiment of the present invention includes a first evaporator and a dehumidification module connected to the first evaporator. The dehumidification module is used to condense and dehumidify the air flowing out of the return air outlet of the drying room. The dehumidification module is connect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com