A kind of warp-knitted imitation single-face woolen fabric and preparation method thereof

A single-sided, woolen technology, which is applied in warp knitting, textiles, papermaking, knitting, etc., can solve the problems of easy detachment, and achieve the effect of good warmth retention, plump hand feeling and not easy detachment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

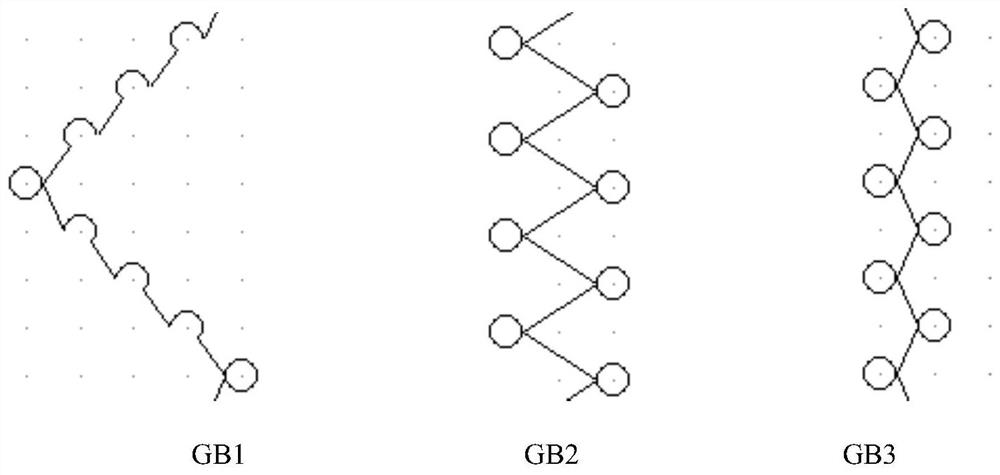

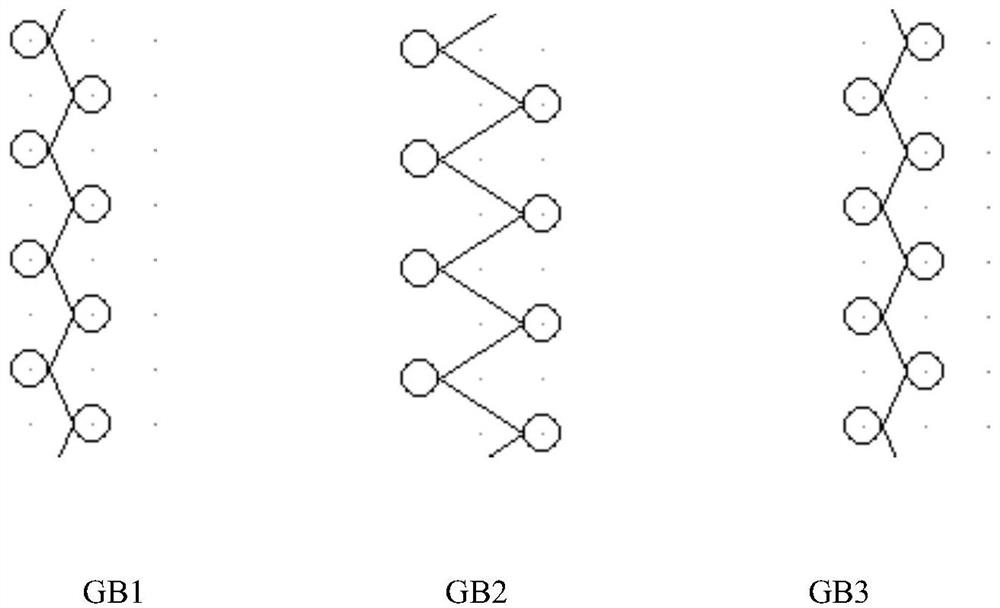

Method used

Image

Examples

Embodiment 1

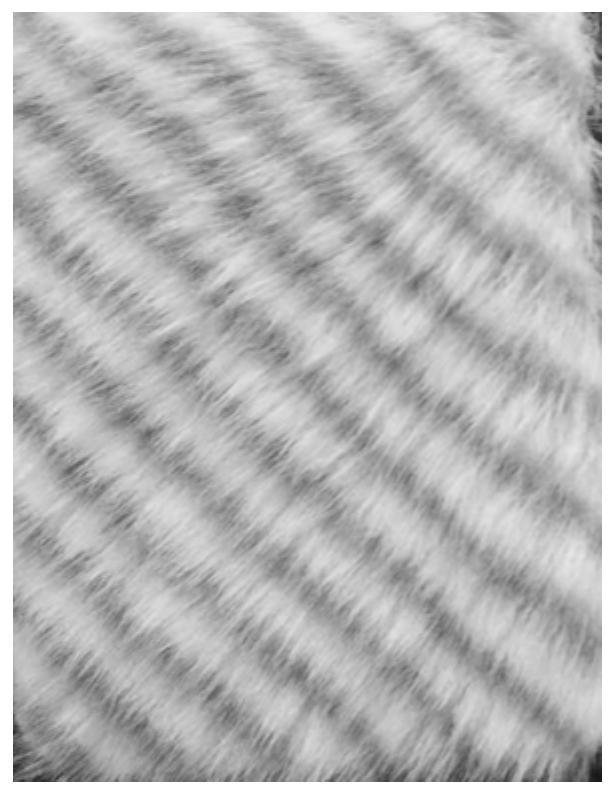

[0043]A warp-knitted imitated single-sided woolen fabric, consisting of the following mass percentage components: 50s polyester half fleece fancy colored yarn A is 17.0%, 50s polyester half fleece fancy colored yarn B is 17.0%, and 50D polyester is 66.0%. The fabric uses two kinds of polyester half fleece yarns on the front to wear a satin weave to form a herringbone effect of imitating a single-sided woolen fabric.

[0044]The preparation process of the fabric includes: single comb structure selection, preparation procedures, warping, weaving and shaping.

[0045]1) Material selection: 20s~50s polyester half fancy colored yarns A and B, 50D~100D polyester DTY;

[0046]2) Warping: The temperature and humidity of the warping site: temperature 25±1℃, relative humidity 65±5%, high and stable temperature and humidity help the surface of polyester half fleece yarn to be soft and anti-static, and to avoid yarn The threads are entangled with each other, which is beneficial to the production of warp...

Embodiment 2

[0070]A warp-knitted imitation single-sided woolen fabric composed of the following mass percentage components: 20s polyester half fleece fancy colored yarn A is 28.0%, 20s polyester half fleece fancy colored yarn B is 28.0%, and 100D polyester is 44.0%. The fabric uses two kinds of polyester half fleece yarns on the front to wear a satin weave to form a sesame dot effect of imitating single-sided woolen fabric.

[0071]The preparation process of the fabric includes: single comb structure selection, preparation procedures, warping, weaving and shaping.

[0072]1) Material selection: 20s~50s polyester half fancy colored yarns A and B, 50D~100D polyester DTY;

[0073]2) Warping: The temperature and humidity of the warping site: temperature 25±1℃, relative humidity 65±5%, high and stable temperature and humidity help the surface of polyester half fleece yarn to be soft and anti-static, and to avoid yarn The yarns are entangled with each other, which is beneficial to the production of warp knitt...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Basis weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com