Mussel-imitated underwater high-viscosity hydrogel preparation method

A hydrogel and high-viscosity technology, which is applied in the field of preparation of underwater high-viscosity hydrogel, can solve problems such as adhesion and poor biocompatibility, and achieve increased underwater adhesion, good biocompatibility, and water Obvious effect under the adhesion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

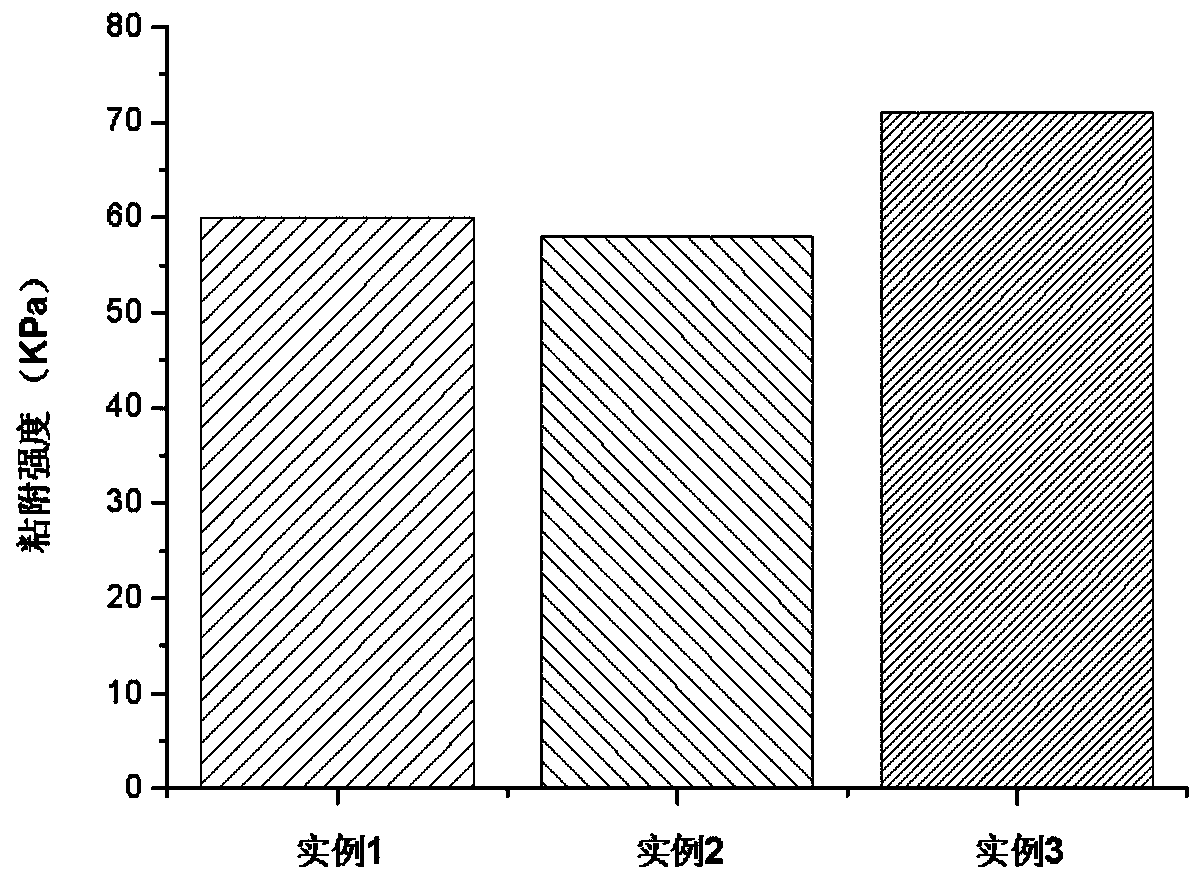

Embodiment 1

[0028] A preparation method of an underwater high-viscosity hydrogel imitating mussels, the preparation method comprising the following steps:

[0029] 1) Dissolve 1g chitosan in 50mL acetic acid (2%, v / v) to make chitosan acetic acid solution;

[0030] 2) Add 0.95g HCA, 0.95g EDC, 0.58g NHS to the solution prepared in step (1), adjust the pH to 5, and react for 10 hours;

[0031] 3) Transfer the solution obtained in step (2) to a dialysis zone with a molecular cut-off of 3500KDa, dialyze in water with pH=5 for 2 days, take the retentate and freeze-dry it for 48 hours to obtain catechol-grafted chitosan ;

[0032] 4) Dissolving 0.25 g of catechol-grafted chitosan obtained in step (3) in 10 mL of water;

[0033] 5) Dissolve 1g of dextran in 50mL of water to make an aqueous solution of dextran;

[0034] 6) Add 0.825g of sodium periodate to the solution prepared in step (5), and add 1mL of ethylene glycol to terminate the reaction after 6 hours of dark reaction;

[0035] 7) T...

Embodiment 2

[0039] A preparation method of an underwater high-viscosity hydrogel imitating mussels, the preparation method comprising the following steps:

[0040] 1) Dissolve 2g chitosan in 100mL acetic acid (2%, v / v) to make chitosan acetic acid solution;

[0041] 2) Add 1.9g HCA, 1.9g EDC, 1.16g NHS to the solution prepared in step (1), adjust the pH to 5, and react for 10 hours;

[0042] 3) Transfer the solution obtained in step (2) to a dialysis zone with a molecular cut-off of 10,000 KDa, dialyze in water with pH=5 for 2 days, take the retentate and freeze-dry it for 24 hours to obtain catechol-grafted chitosan ;

[0043] 4) Dissolving 0.25 g of catechol-grafted chitosan obtained in step (3) in 10 mL of water;

[0044] 5) Dissolve 1g of dextran in 50mL of water to make an aqueous solution of dextran;

[0045] 6) Add 0.825g of sodium periodate to the solution prepared in step (5), and add 1mL of ethylene glycol to terminate the reaction after 10 hours of dark reaction;

[0046] 7...

Embodiment 3

[0050] A preparation method of an underwater high-viscosity hydrogel imitating mussels, the preparation method comprising the following steps:

[0051] 1) Dissolve 2g chitosan in 100mL acetic acid (2%, v / v) to make chitosan acetic acid solution;

[0052] 2) Add 1.9g HCA, 1.9g EDC, 1.16g NHS to the solution prepared in step (1), adjust the pH to 5, and react for 10 hours;

[0053] 3) Transfer the solution obtained in step (2) to a dialysis zone with a molecular cut-off of 14,000 KDa, dialyze in water with pH=5 for 3 days, take the retentate and freeze-dry it for 48 hours to obtain catechol-grafted chitosan ;

[0054] 4) Dissolving 0.3 g of catechol-grafted chitosan obtained in step (3) in 10 mL of water;

[0055] 5) Dissolve 1g of dextran in 50mL of water to make an aqueous solution of dextran;

[0056] 6) Add 0.825g of sodium periodate to the solution prepared in step (5), and react in the dark for 12 hours, then add 1mL of ethylene glycol to terminate the reaction;

[005...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com