Miniature candy and preparation method thereof

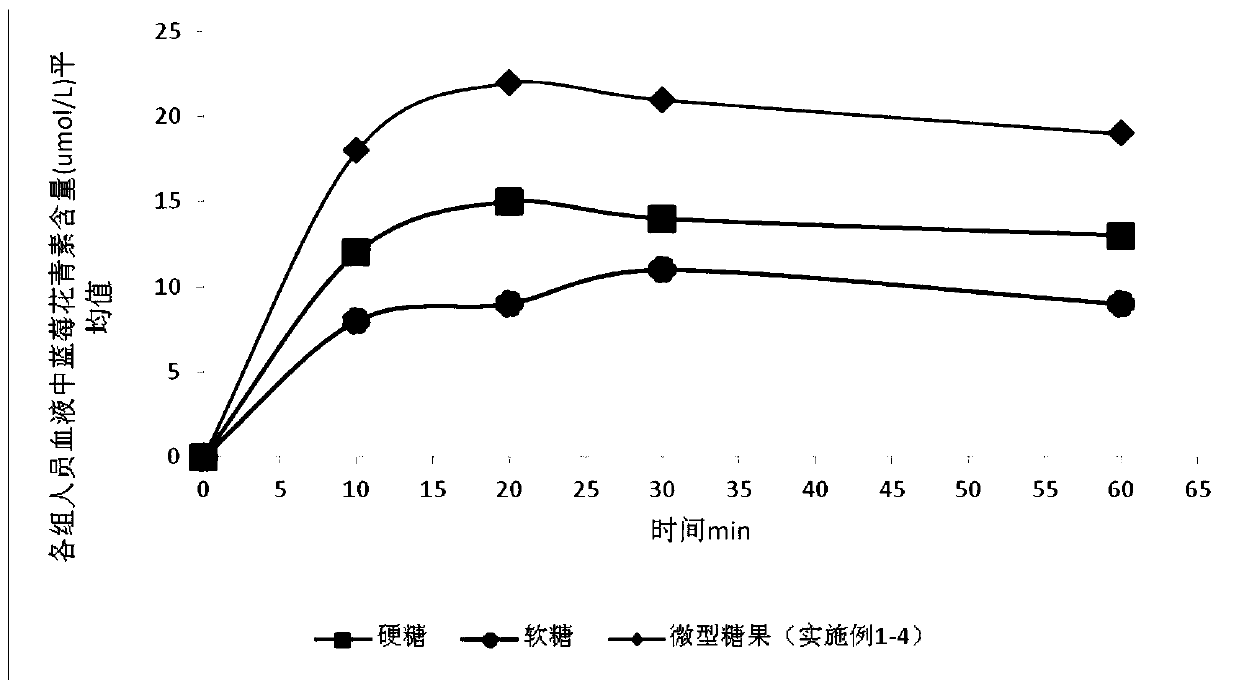

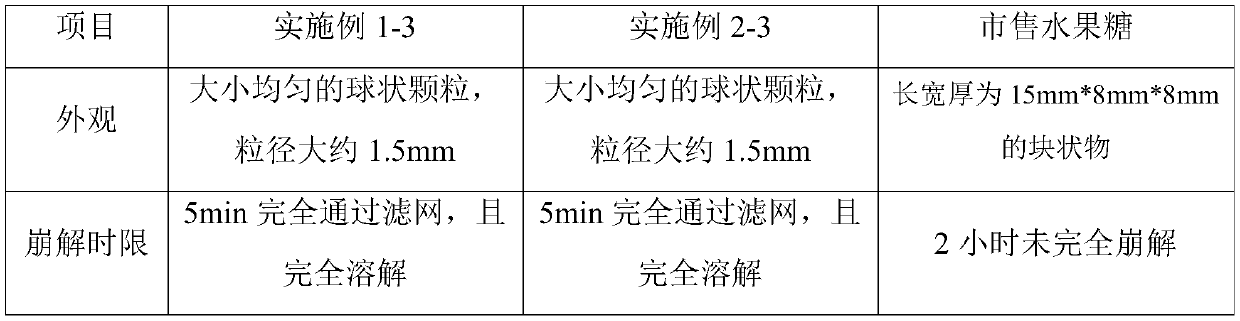

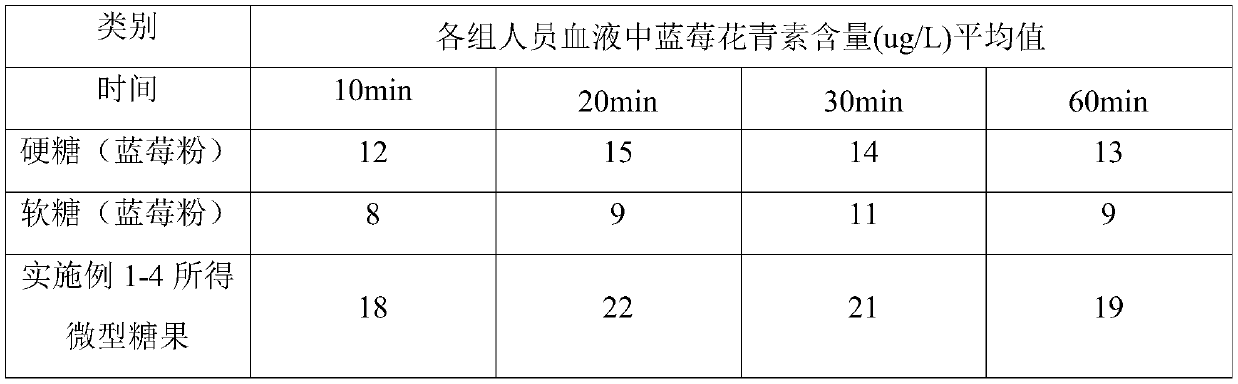

A miniature and candy technology, applied in the direction of confectionery, confectionery industry, food science, etc., can solve the problems of sticking to the teeth, affecting oral hygiene, hurting the teeth, etc., and achieving the effect of high absorption rate, comfortable taste and improved absorption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-1

[0037] A preparation method of miniature candies, comprising the following steps:

[0038] 1) Prepare the powdered sugar mixture, sieve the powdered sugar mixture, take the powdered sugar mixture with a particle size of 0.2-0.25mm as the core I, put 10 parts by mass of the core I into the water chestnut pot, repeat the operation ① until 80wt% The particle size of the particles is 0.3 ~ 0.35mm;

[0039] Operation ①: put the adhesive into the pressure tank, the pressure tank is connected with a spray gun, and the pressure in the pressure tank is 0.4Mpa. Continuously spray the adhesive into the water chestnut pot through the spray gun for 1.5 minutes, then add 0.5 parts by mass of excipients, dry at 25°C for 2 minutes, and spray 0.1 parts by mass of the adhesive per minute;

[0040] Wherein, the powdered sugar mixture is a mixture of sucrose and starch with a mass ratio of 4:1.

[0041] The binder is 50 wt% sucrose aqueous solution, and the viscosity of the binder is 26 centipo...

Embodiment 1-2

[0045] A preparation method of miniature candies, comprising the following steps:

[0046] 1) Prepare the powdered sugar mixture, sieve the powdered sugar mixture, take the powdered sugar mixture with a particle size of 0.3-0.35 mm as the core I, put 30 parts by mass of the core I into the water chestnut pot, and repeat the operation ① until it reaches 85 wt% The particle size of the particles is 0.9 ~ 1mm;

[0047] Operation ①: put the adhesive into the pressure tank, the pressure tank is connected with a spray gun, and the pressure in the pressure tank is 0.45Mpa. Continuously spray the adhesive into the water chestnut pot through the spray gun for 2 minutes, then add 1 part by mass of excipients, and dry at 30°C for 2.5 minutes, wherein the amount of adhesive sprayed per minute is 0.5 parts by mass;

[0048] Wherein, the powdered sugar mixture is a mixture of sucrose: isomalt: maltodextrin with a mass ratio of 3.5:1:0.5.

[0049] The binder is a 6 wt% aqueous solution of ...

Embodiment 1-3

[0053] A preparation method of miniature candies, comprising the following steps:

[0054] 1) Prepare the powdered sugar mixture, sieve the powdered sugar mixture, take the powdered sugar mixture with a particle size of 0.35-0.4mm as the core I, put 60 parts by mass of the core I into the water chestnut pot, repeat the operation ① until 84wt% The particle size of the particles is 1.4 ~ 1.6mm;

[0055]Operation ①: put the adhesive into the pressure tank, the pressure tank is connected with a spray gun, and the pressure in the pressure tank is 0.5Mpa. Spray the adhesive into the water chestnut pot for 3 minutes through the spray gun, then add 2 parts by mass of excipients, and dry at 30°C for 5 minutes, wherein the amount of adhesive sprayed per minute is 0.3 parts by mass;

[0056] Wherein, the powdered sugar mixture is a mixture of maltose: glucose: xylitol: dextrin mass ratio 1:1:1.5:0.5.

[0057] The binder is 5 wt % hydroxypropyl methylcellulose aqueous solution, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com