Hand-propelled wheeled vehicle

A push-wheel type, vehicle technology, applied in the field of vehicles, can solve the problems of easy misoperation, difficult control, complicated operation procedures, etc., and achieve the effect of reducing misoperation, reducing turning radius, and simple operation procedures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 11

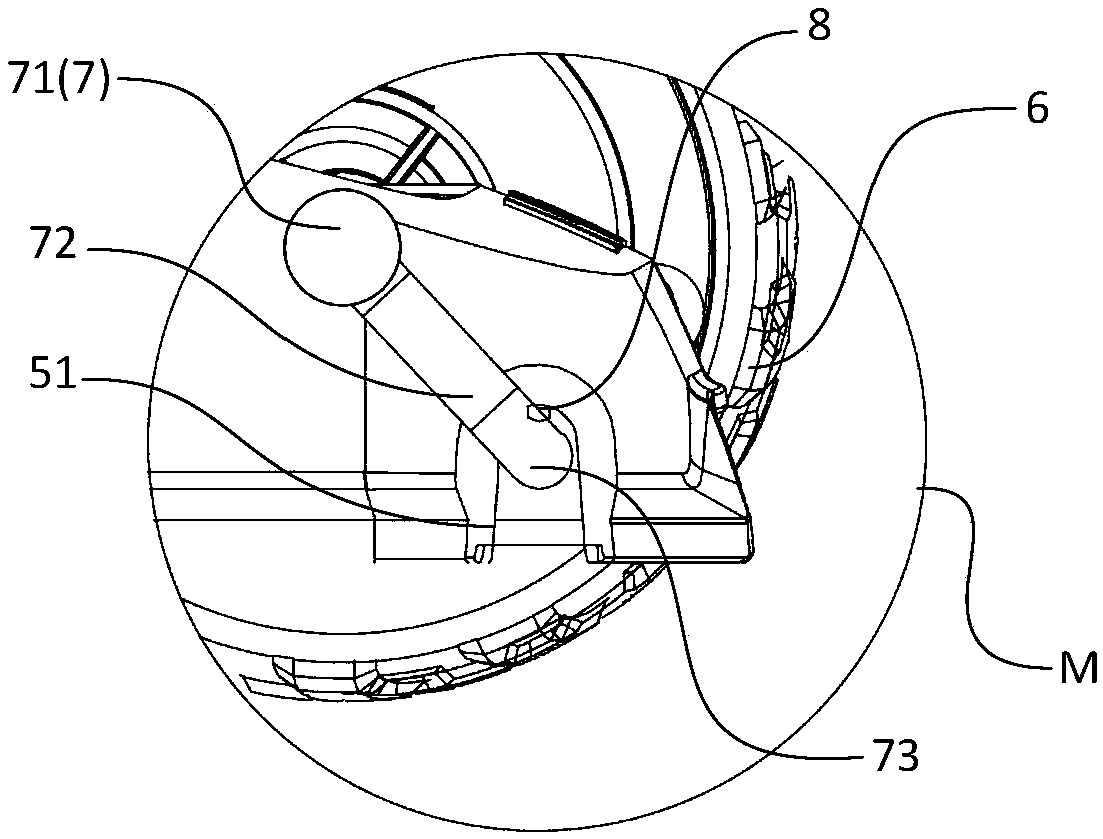

[0080] figure 2 A schematic structural view of a push-wheel vehicle according to an embodiment of the present invention is shown. image 3 show figure 2 Partial enlarged view of M in middle.

[0081] Such as figure 2 and image 3 As shown, the push-wheel vehicle may include: an operating rod 3 , and the operating rod 3 may include a grip portion 1 . Described walking mechanism can comprise front wheel 6 and rear wheel 4, figure 2 The self-driving mechanism is not shown. The push-wheel vehicle can also include: bottom shell 5 and front wheel shaft 7, and described bottom shell 5 comprises the mounting hole (not shown) that supports described front wheel shaft 7; Described front wheel 6 is installed by described front wheel shaft 7 On one side of the bottom shell 5 , the front wheel shaft 7 includes a shaft main body 71 rotatably connected to the front wheel, and the shaft main body 71 can move in the installation hole.

[0082] Such as figure 2 As shown, a second s...

example 12

[0099] In another possible implementation manner, the contact 8 may be located at the top of the installation hole, and a switch trigger part may be provided on the upper side of the shaft main body 71 . In other words, the switch trigger part can be directly disposed on the shaft main body 71 . Figure 8a A schematic diagram showing the structure of contacts and mounting holes according to an embodiment of the present invention, such as Figure 8a As shown, the contact 8 is located on the top of the mounting hole.

[0100] At this time, when the front wheel 6 is above the ground, due to the weight of the front wheel 6 and the shaft body 71, the shaft body 71 moves to the lower side of the installation hole, and the switch trigger part is disconnected from the The connection of the contact 8: when the front wheel 6 touches the ground, due to the weight of the bottom case 5, the shaft main body 71 moves to the upper side of the installation hole, and the switch trigger part is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com