Overheating power cutoff method for switch and electric equipment

A technology for electrical equipment and overheating, which is applied to parts of tumbler/rocker switches and parts of thermal switches, etc. It can solve problems such as incomplete contact of sockets, incomplete insertion, and temperature difference between bimetallic strips. achieve costly improvements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

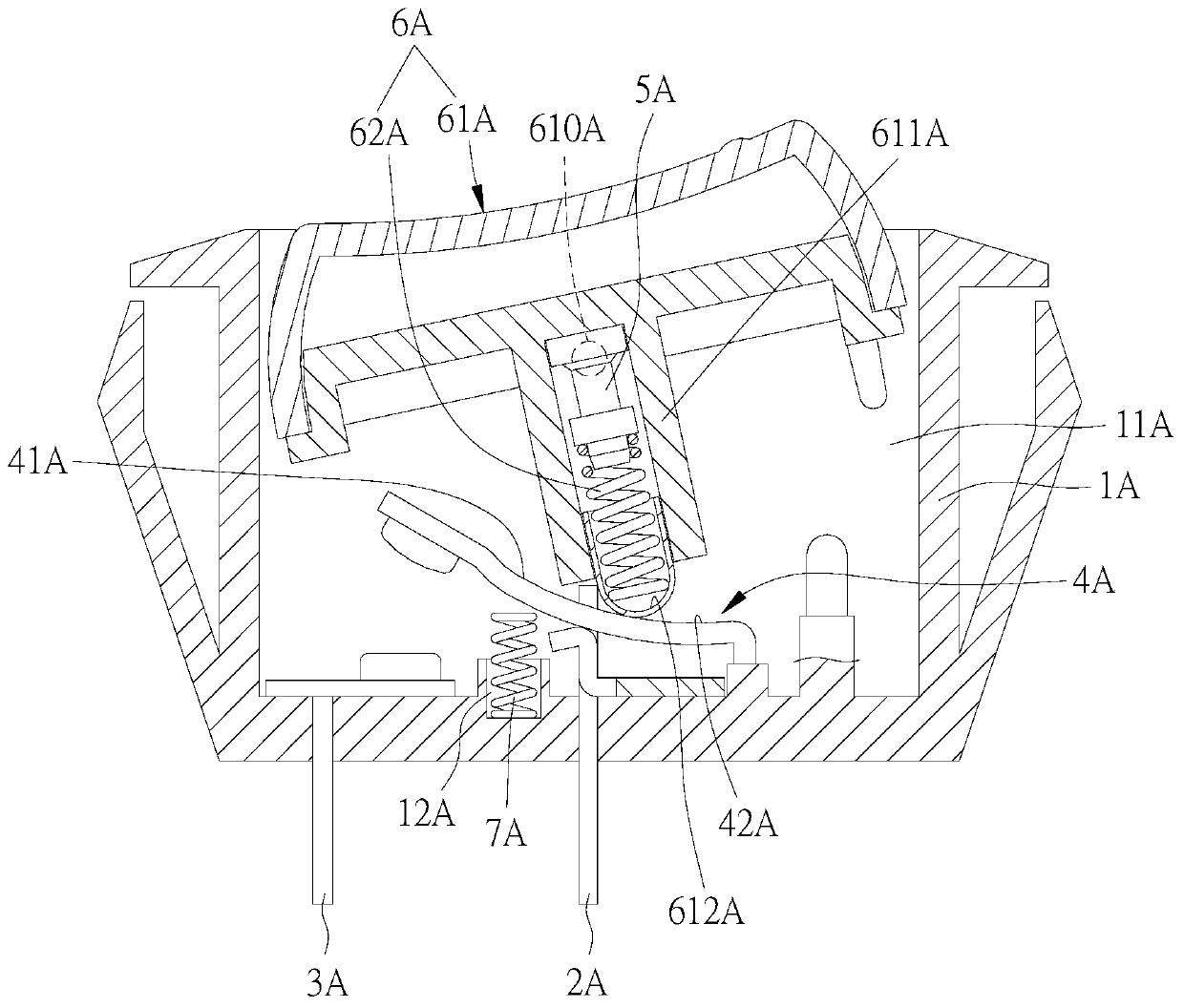

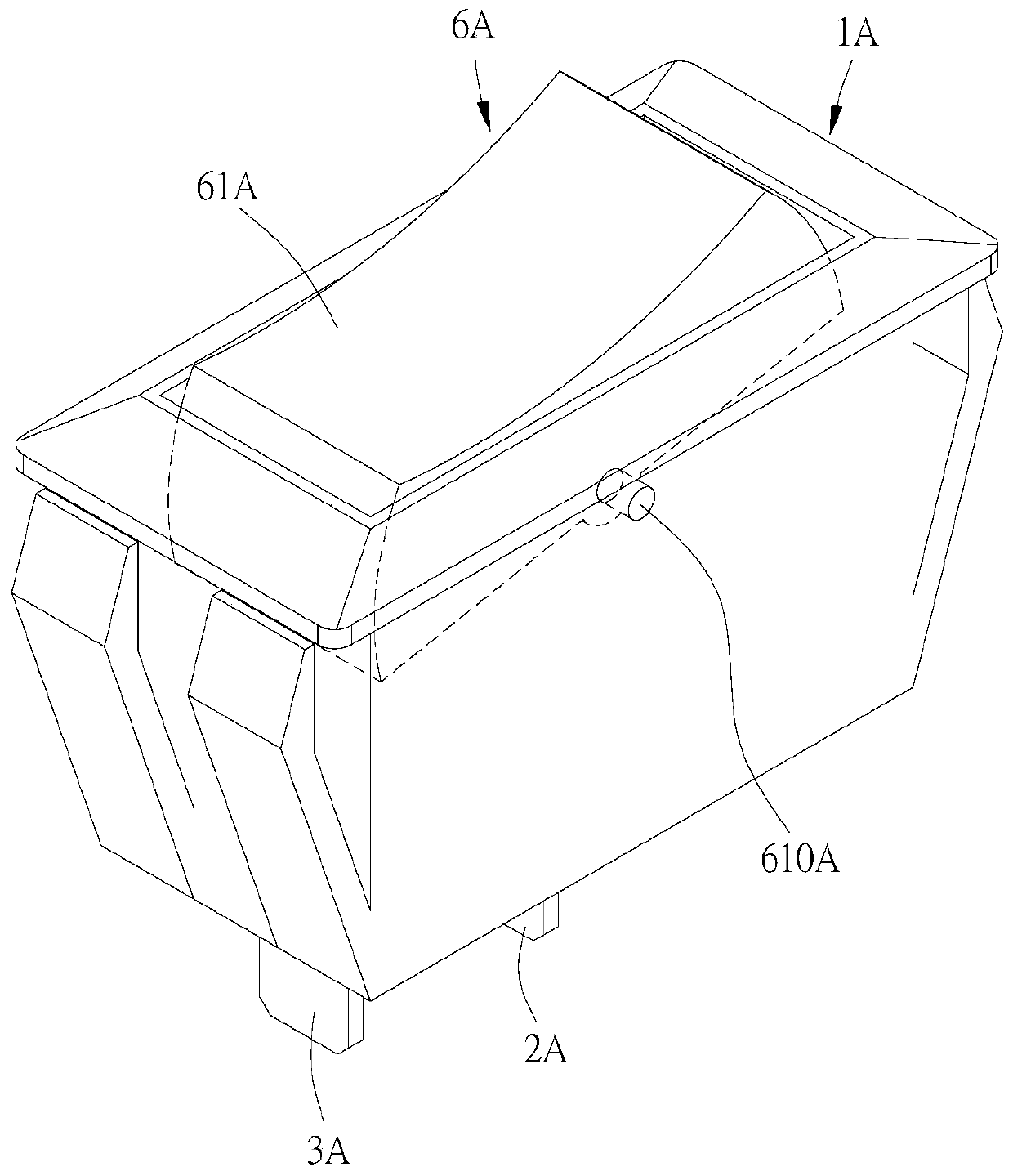

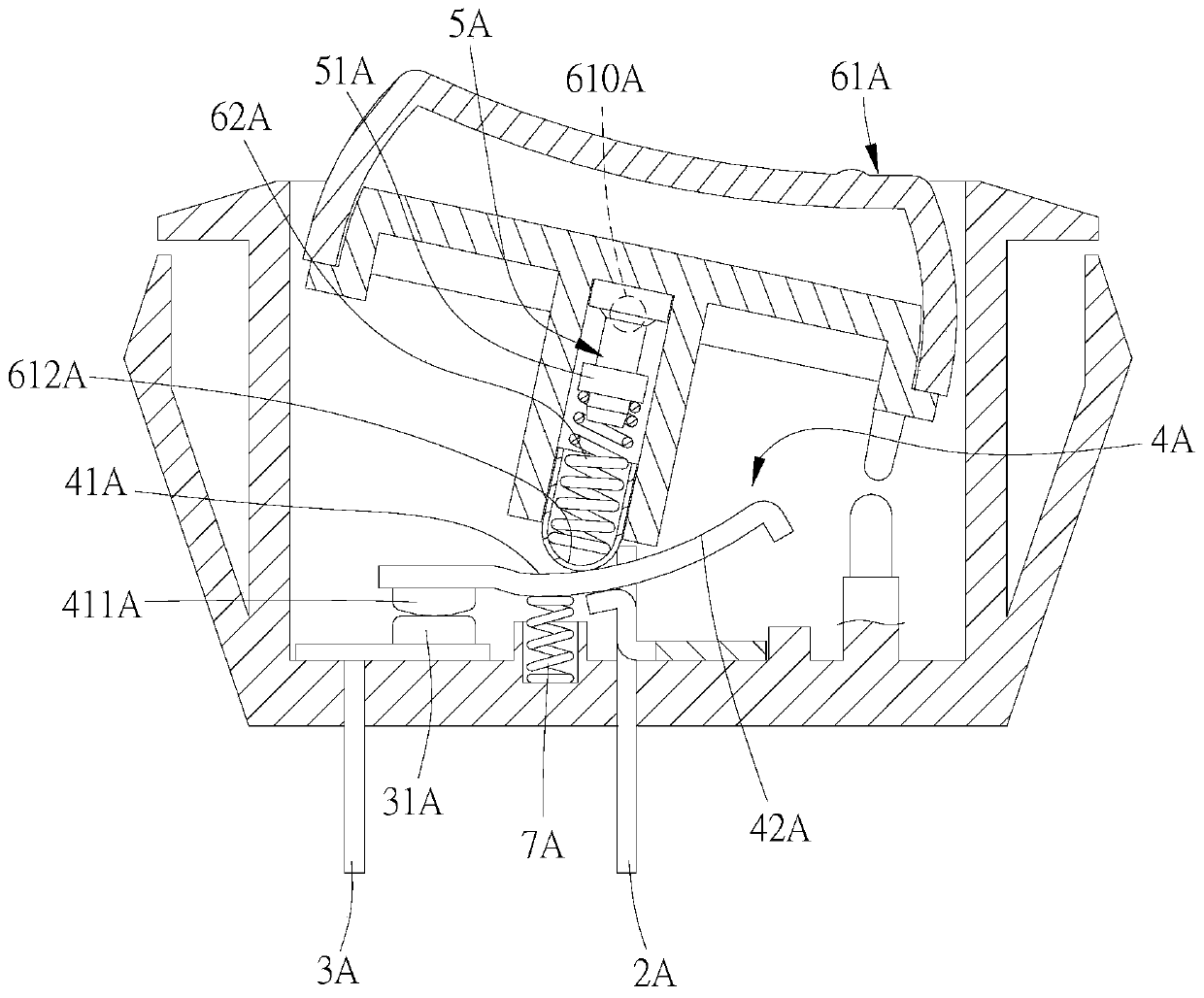

[0058] In view of the above technical features, the main effects of the method for overheating and power-off of a switch or an electrical device of the present invention will be clearly presented in the following embodiments.

[0059] In the cross-sectional views presented in the following embodiments, the relevant operating states and torques are described as follows:

[0060] The operating members (61A, 61B, 61C, 61D, 61E, 61F, 61G) of the rocker switch can be switched to an open position and a closed position.

[0061] Power-off torque refers to when the operating member (61A, 61B, 61C, 61D, 61E, 61F, 61G) is in the closed position, the first elastic force acts on the movable conductive member (4A, 4B, 4C, 4D, 4E, 4F, 4G) ), so that the movable conductive parts (4A, 4B, 4C, 4D, 4E, 4F, 4G) have a clockwise rotation trend around the fulcrum of the first conductive parts (2A, 2B, 2C, 2D, 2E, 2F, 2G) torque.

[0062] The first torque refers to when the operating member (61A,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com