Anti-rollover control method and device of construction machinery and construction machinery

A technology of engineering machinery and control methods, applied in the direction of control without feedback, can solve the problems of lack of universal correctness and lag of anti-rollover control technology, and achieve remarkable predictability, universal correctness, and high safety guarantee effect of ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

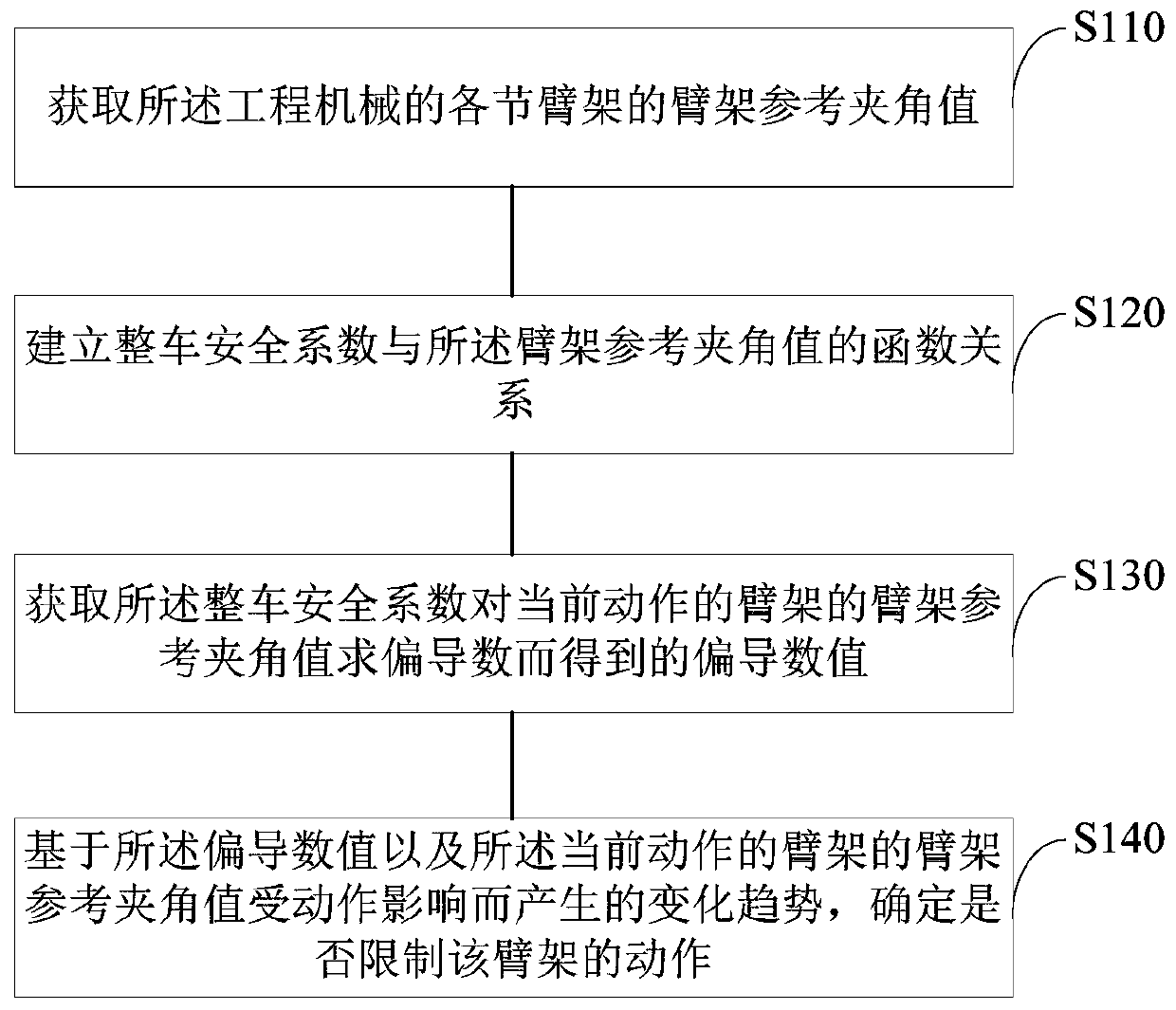

[0038] figure 1 It is a schematic flow chart of the anti-overturn control method for construction machinery provided in Embodiment 1 of the present invention, wherein the construction machinery includes a boom pump truck, a lifting machine with a folding arm, a folding arm fire truck, and the like. Such as figure 1 As shown, the anti-rollover control method may include the following steps:

[0039] Step S110, acquiring the boom reference included angle value of each boom section of the construction machine.

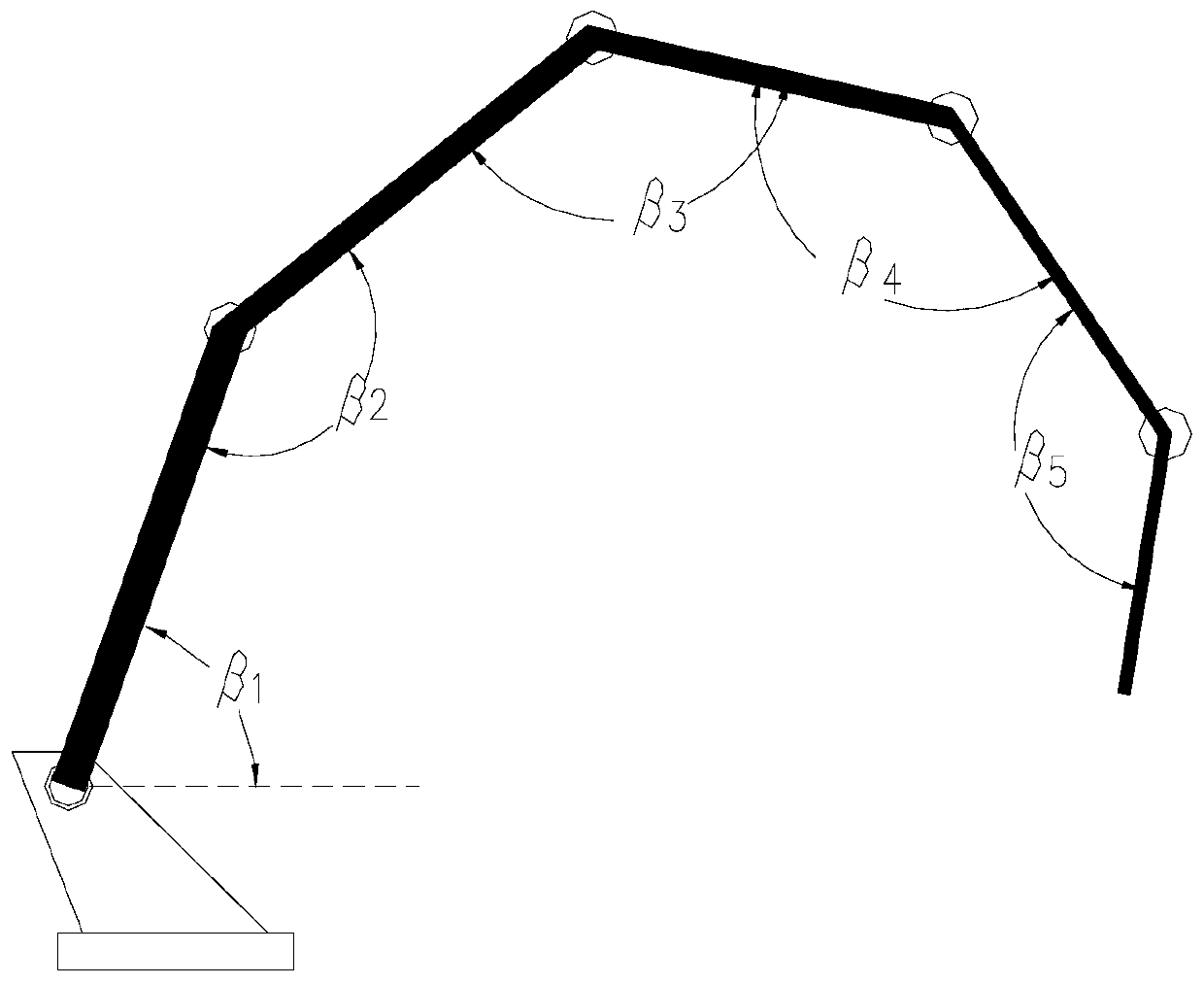

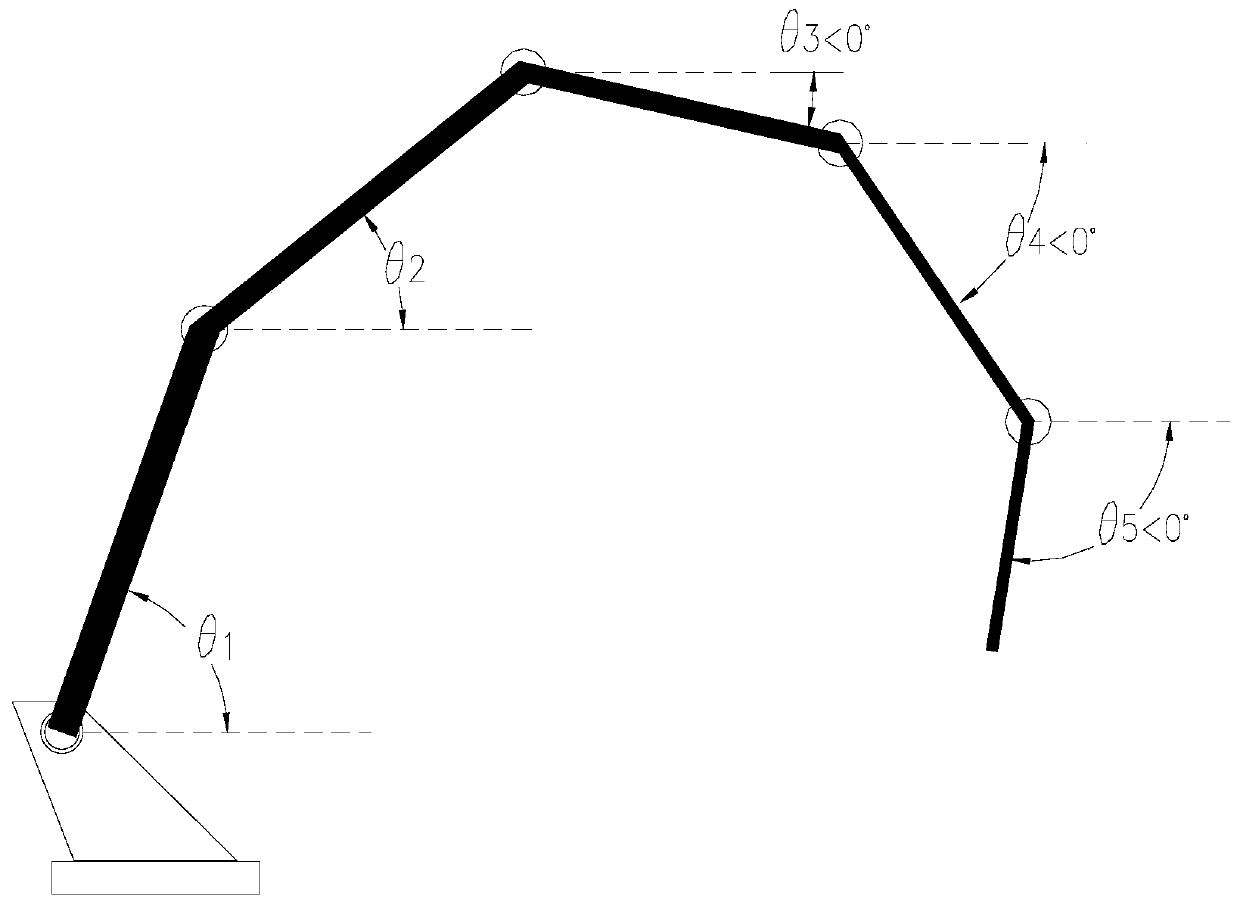

[0040] Wherein, the reference angle value of the boom is intended to indicate the value of the included angle of the boom, figure 2 That is, the schematic diagram of the included angle of the boom in the embodiment of the present invention, in the figure β i Indicates the jib angle formed by the previous jib and the i-th jib, where i is 1, 2, 3, 4 and 5. However, it should be noted that the reference angle value of the jib here is also intended to use the word "refer...

Embodiment 2

[0082] Before the above-mentioned embodiment 1 uses the criterion of combining the "partial derivative value of the vehicle safety factor with respect to the reference angle value of the boom" and "the change trend of the reference angle value of the boom" to make a safety judgment, the embodiment of the present invention The second option can be initially judged through the vehicle safety factor. Figure 6 It is a schematic flow chart of the second embodiment of the present invention to preliminarily determine whether to limit the movement of the boom according to the safety factor of the whole vehicle. Such as Figure 6 As shown, after establishing the functional relationship between the safety factor of the vehicle and the reference angle value of the boom in step S120, and before calculating the partial derivative value in step S130, the anti-rollover control method may further include:

[0083] Step S610, calculating the vehicle safety factor according to the reference a...

Embodiment 3

[0095] Figure 7 It is a structural schematic diagram of an anti-rollover control device for construction machinery in Embodiment 3 of the present invention. The anti-rollover control device and the anti-rollover control method in Embodiment 1 are based on the same inventive idea. Such as Figure 7 As shown, the anti-rollover control device may include: a storage module 10 for storing computer-executable instructions; and a control module 20 for executing the computer-executable instructions to perform the following operations:

[0096] Acquiring the boom reference angle value of each boom section of the construction machinery;

[0097] Establishing the functional relationship between the safety factor of the whole vehicle and the reference included angle value of the boom, and obtaining the partial derivative value obtained by calculating the partial derivative of the safety factor of the whole vehicle with respect to the reference included angle value of the boom of the cur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com