Oil injection float valve for petroleum drilling

A technology of oil drilling and oil injection, which is applied in earthwork drilling, wellbore flushing, wellbore/well parts, etc. It can solve problems such as plastic deformation of valve sleeves, easy occurrence of sand sticking, increase of piston action resistance, etc., and improve strength , Improve the sealing effect and pressure resistance, and reduce the resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

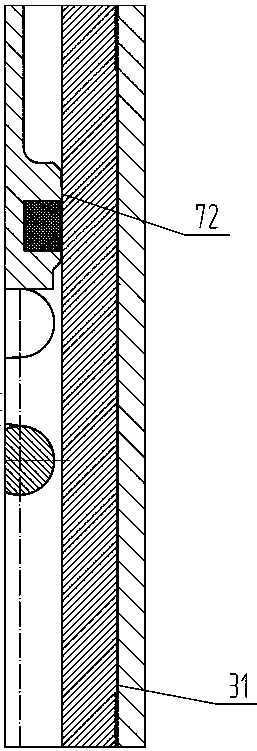

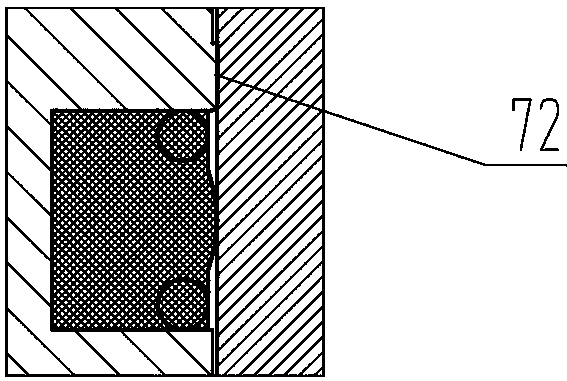

[0033] refer to Figure 1-5 , an oil injection float valve for oil drilling, its main structure is as follows:

[0034] The oil injection float valve includes the oil injection float valve casing 1 and the fixed seat 11 and the valve sleeve 3 which are connected sequentially from top to bottom inside it; the upper end of the fixed seat 11 is open and the lower end is closed. They are connected to each other and form a first annular cavity 16 between the outer walls of the two and the oil injection floating valve housing 1, and the inner cavity of the fixed seat 11 is provided with one or more first holes 17 that communicate with the first annular cavity 16 , the upper inner cavity of the valve sleeve 3 is provided with one or more second holes 18 that communicate with the first annular cavity 16 .

[0035]A stepped oil filling piston 7 and a protective tube 15 connected to each other are installed in the valve sleeve 3 from top to bottom; the stepped oil filling piston 7 is a...

Embodiment 2

[0045] refer to Figure 1-5 , an oil injection float valve for oil drilling, on the basis of the technical solution disclosed in Embodiment 1, it also includes: the fixed seat 11 and the valve sleeve 3 are fixed together by radially arranged slotted headless screws 13, that is, the present The straight pin or hexagon socket cap screw in the prior art is replaced by the slotted headless screw 13. Due to its headless thread structure, it can ensure the fixing effect while occupying less space and less exposed area, which can improve the erosion resistance.

Embodiment 3

[0047] refer to Figure 1-5 , an oil injection float valve for oil drilling, on the basis of the technical solution disclosed in embodiment 1 or 2, also includes: Y-shaped sealing ring 10, S-shaped sealing ring 6 are all made of elastic memory composite material, valve sleeve 3 and stepped The oil injection piston 7 is made of shape memory composite material. Its working principle in this valve is: Y-shaped sealing ring 10, S-shaped sealing ring 6, valve sleeve 3 and stepped oil filling piston 7 will be deformed during pressure test or work, and elastic memory composite materials and shape memory materials are used respectively. Composite materials can restore the original dimensional accuracy after pressure test or work, improve product use effect and prolong service life.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com