Modified additive for paper pulp molded products, preparation method and application thereof

A technology of molded products and additives, which is applied in the process of adding pulp raw materials, adding non-fiber pulp, paper, etc., can solve problems that do not conform to the development concept of green environmental protection, increase production costs, and cumbersome operations, so as to save time, cost and Equipment cost, reduced chip shedding, simple preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

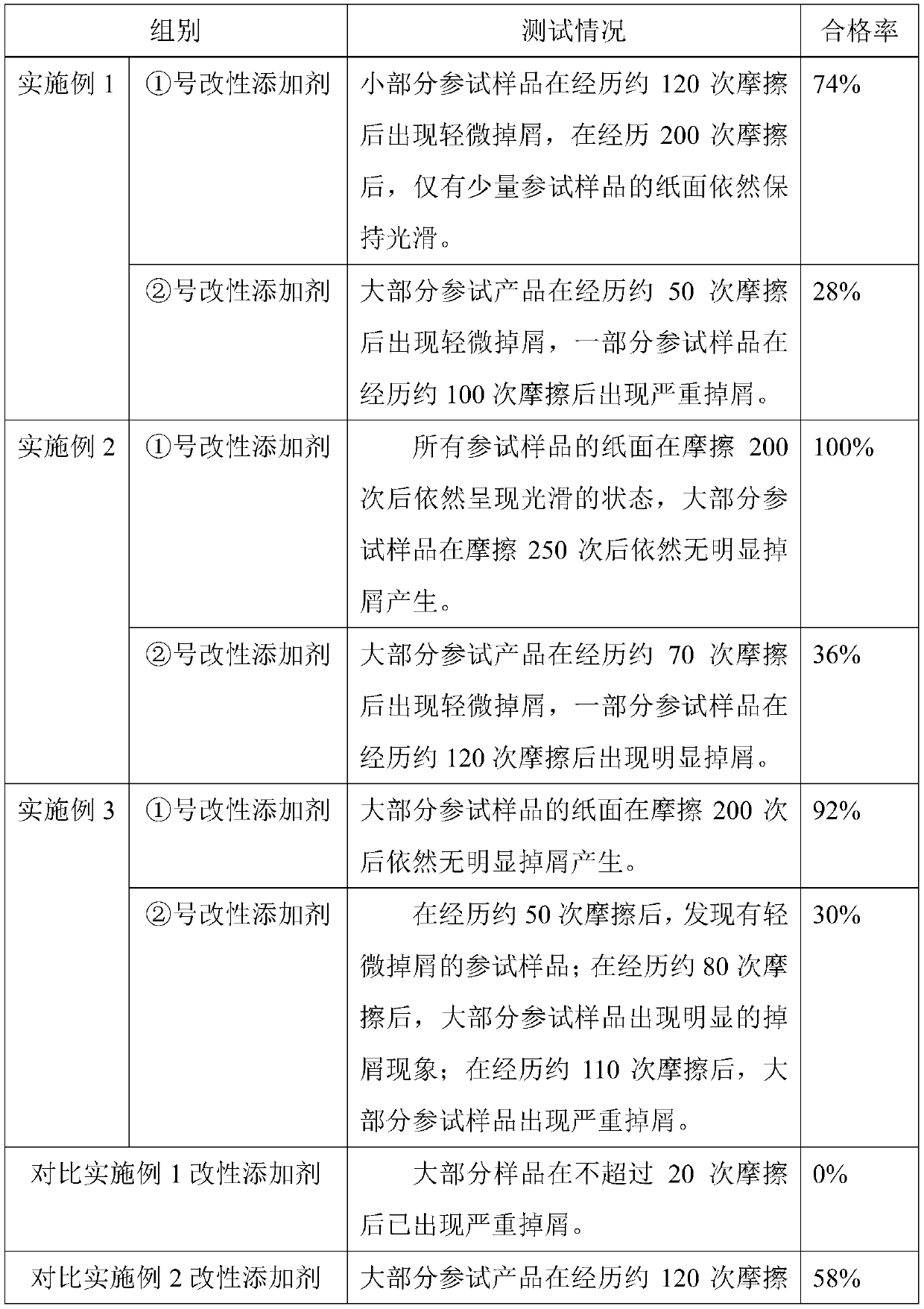

Examples

Embodiment 1

[0025] 1. Preparation of cationic starch

[0026] (1) According to the mass ratio of dry cornstarch: 3-chloro-2-hydroxypropyltrimethylammonium chloride (CTA) = 1:0.45, take a certain amount according to the molar ratio of CTA: sodium hydroxide = 1: 1.2 amount of dry cornstarch CTA and sodium hydroxide;

[0027] (2) Activate sodium hydroxide, CTA and a small amount of water for 10 minutes at a temperature lower than 10°C;

[0028] (3) Spray the activated medicine into cornstarch, stir evenly, and pre-dry at 50°C for 1 hour;

[0029] (4) Take out the product obtained in step (3), put it in an airtight container after crushing, and keep it warm at 85° C. for 4 hours to obtain a semi-finished product;

[0030] (5) Utilize 80% ethanol solution to wash the semi-finished product until the filtered washing liquid does not contain Cl - , dried to prepare the cationic starch of this embodiment.

[0031] 2. Preparation of modified additives for pulp moldings

[0032] In this example...

Embodiment 2

[0051] 1. Preparation of cationic starch

[0052] (1) According to the mass ratio of dry corn starch: N-(2,3-epoxypropyl) trimethyl ammonium chloride (GTA) = 1:0.15, according to the molar ratio of GTA: sodium hydroxide = 1:1 Take a certain amount of dry cornstarch, GTA and sodium hydroxide;

[0053] (2) Sodium hydroxide is dissolved in an appropriate amount of water, and it is cooled;

[0054] (3) GTA is added in the sodium hydroxide solution, fully dissolved;

[0055] (4) Add cornstarch to the solution obtained in step (3), fully stir until evenly mixed;

[0056] (5) Move the mixed solution prepared in step (4) into an oven and keep it warm at 80° C. for 4 hours to obtain a white semi-finished product;

[0057] (6) Utilize 80% ethanol solution to wash the semi-finished product until the filtered washing liquid does not contain Cl - , dried to prepare the cationic starch of this embodiment.

[0058] 2. Preparation of modified additives for pulp moldings

[0059] In this...

Embodiment 3

[0078] 1. Preparation of cationic starch

[0079] (1) According to the mass ratio of dry tapioca starch: N-(2,3-epoxypropyl) trimethyl ammonium chloride (GTA) = 1:0.15, according to the molar ratio of GTA: sodium hydroxide = 1:1 Take a certain amount of dry tapioca starch, GTA and sodium hydroxide;

[0080] (2) Sodium hydroxide is dissolved in an appropriate amount of water, and it is cooled;

[0081] (3) GTA is added in the sodium hydroxide solution, fully dissolved;

[0082] (4) Add tapioca starch in the solution gained in step (3), fully stir until evenly mixed;

[0083] (5) Move the mixed solution prepared in step (4) into an oven and keep it warm at 80° C. for 4 hours to obtain a white semi-finished product;

[0084] (6) Utilize 80% ethanol solution to wash the semi-finished product until the filtered washing liquid does not contain Cl - , dried to prepare the cationic starch of this embodiment.

[0085] 2. Preparation of modified additives for pulp moldings

[0086...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com