Polyurethane microporous foaming film for persistent antibacterial central venous catheters and preparation method thereof

A polyurethane film and microcellular foaming technology, applied in catheters and other directions, can solve the problems of central venous cannula detachment, bacterial invasion, and poor bacteriostatic effect, so as to prolong the sustained release period, enhance the bacteriostatic effect, and avoid excessive release. quick effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

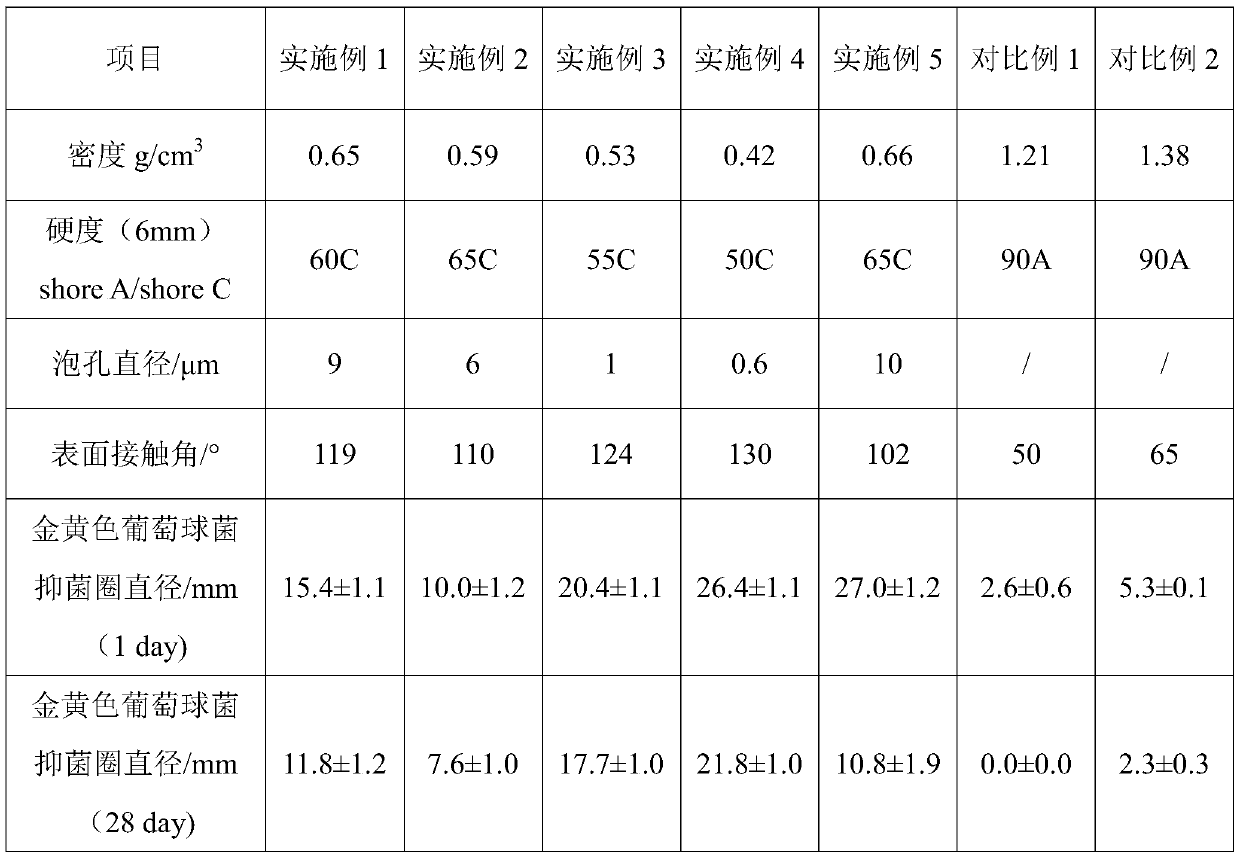

Examples

Embodiment 1

[0030] A kind of polyurethane microporous foam film for central venous tube with persistent antibacterial effect, the preparation method is as follows:

[0031] (1) In terms of parts by mass, 100 parts of PTMEG-500, 0.01 part of nano silicon dioxide and 0.01 part of bismuth octadecanoate catalyst are added to the reactor A equipped with mechanical stirring and thermometer, and the set temperature is 90°C; add 44 parts of MDI to reactor B, set the temperature to 65°C; add 13 parts of BDO to reactor C, set the temperature to 55°C;

[0032] (2) When the temperature of each reactor is stable, the raw material components in reactor A / B / C are mixed and injected into the twin-screw reactor through the high-speed rotating mixing head through the infusion system with precise metering, and the mixed material is in the twin-screw barrel Uniform reaction, the polyurethane film with a thickness of 50 μm and a width of 0.5 m is made by extruding a cast film head;

[0033] (3) Place two ves...

Embodiment 2

[0035] A kind of polyurethane microporous foam film for central venous tube with persistent antibacterial effect, the preparation method is as follows:

[0036] (1) In parts by mass, 100 parts of PPG-2000, 0.1 part of nano-calcium carbonate and 0.02 part of bismuth octadecanoate catalyst are added to reactor A equipped with mechanical stirring and thermometer, and the setting temperature is 100 ℃; Add 57 parts of HMDI into Reactor B, set the temperature at 50°C; Add 24 parts of HQEE into Reactor C, set the temperature at 50°C;

[0037] (2) When the temperature of each reactor is stable, the raw material components in reactor A / B / C are mixed and injected into the twin-screw reactor through the high-speed rotating mixing head through the infusion system with precise metering, and the mixed material is in the twin-screw barrel Uniform reaction, the polyurethane film with thickness of 100μm and width of 0.5m is made by extrusion cast film head;

[0038] (3) In the supercritical b...

Embodiment 3

[0040] A kind of polyurethane microporous foam film for central venous tube with persistent antibacterial effect, the preparation method is as follows:

[0041] (1) In terms of parts by mass, 50 parts of PTMEG-4000, 50 parts of PPG-4000, 0.5 parts of silicon dioxide, 0.5 nanometer calcium carbonate and 0.015 parts of bismuth octadecanoate catalysts are added to the In the reactor A of the thermometer, set the temperature to 90°C; add 60 parts of MDI to the reactor B, and set the temperature to 65°C; add 20 parts of BDO to the reactor C, and set the temperature to 55°C;

[0042] (2) When the temperature of each reactor is stable, the raw material components in reactor A / B / C are mixed and injected into the twin-screw reactor through the high-speed rotating mixing head through the infusion system with precise metering, and the mixed material is in the twin-screw barrel Uniform reaction, the polyurethane film with a thickness of 200μm and a width of 0.5m is made by extruding a cas...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com