Method for preparing organic fertilizer from food waste anaerobic fermentation biogas residue

An anaerobic fermentation, kitchen waste technology, applied in the direction of organic fertilizer, organic fertilizer equipment, organic fertilizer preparation, etc., can solve the problem of affecting the maintenance time of the high temperature stage, the heat loss of the ventilation rate, affecting the composting process, etc., to reduce labor Transshipment procedures, improved conversion rates, adequate exposure to effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

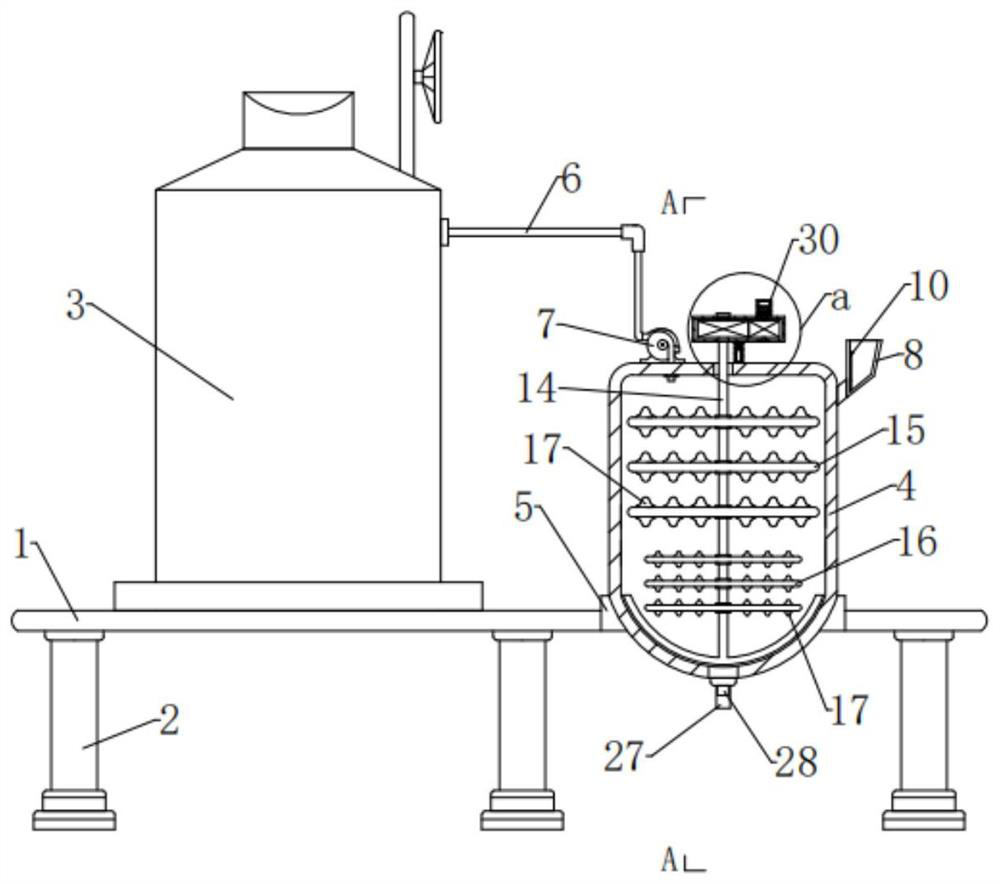

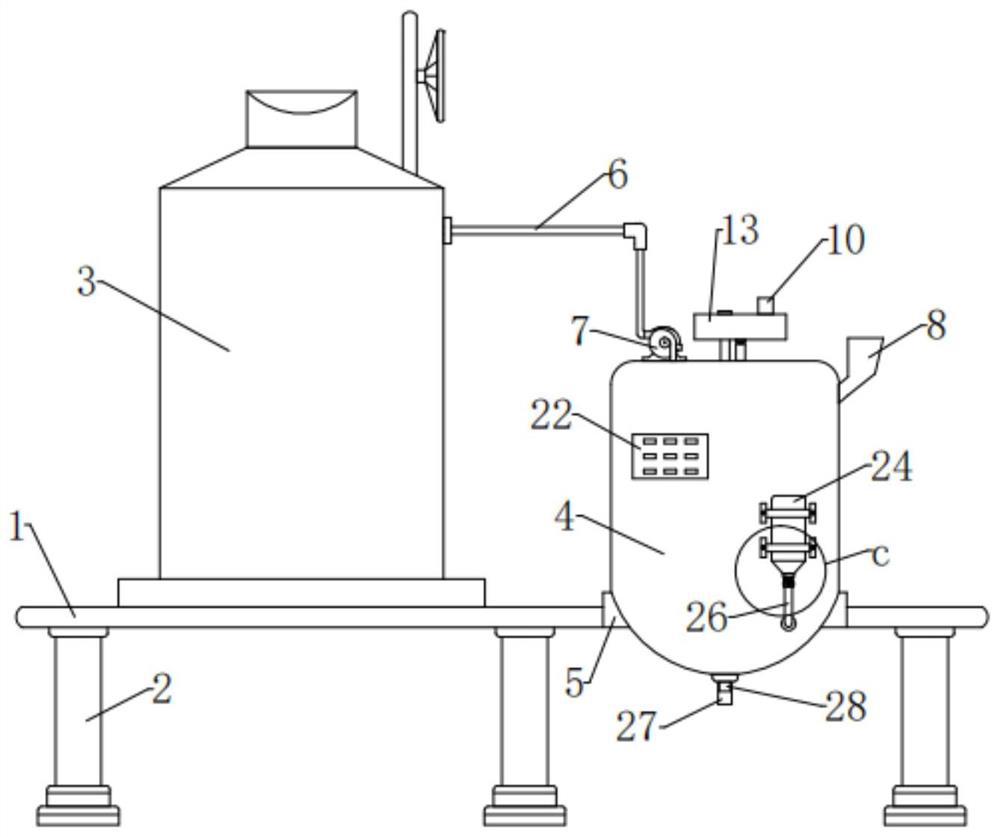

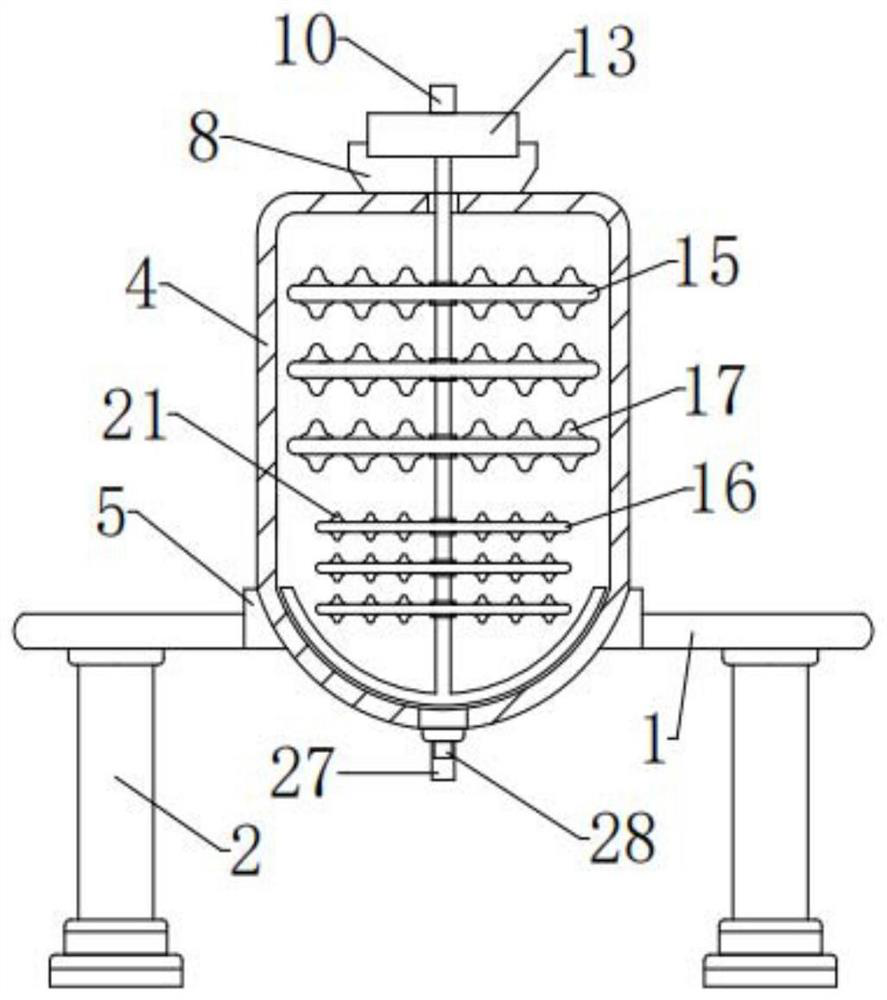

[0046] Below by embodiment and in conjunction with accompanying drawing, the present invention will be further described:

[0047] A method for preparing organic fertilizer by using food waste anaerobic fermentation biogas residue, comprising the following steps:

[0048] The first step is to mix straw or sawdust and decomposed biogas residue compost with new food waste anaerobic fermentation biogas residue, stir evenly and carry out initial aerobic fermentation;

[0049] The second step is to carry out the second aerobic fermentation of the mixed biogas residue after the initial fermentation. The temperature of the aerobic fermentation is controlled at 30°-50°, and sufficient ventilation is ensured. 3-5 hours to stir the biogas residue mixed stockpiling until the completion of aerobic fermentation;

[0050] In the first step, an aerobic composting system for anaerobic fermentation of municipal food waste is used for stirring and primary aerobic fermentation.

[0051] In the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com