Vehicle frame connecting assembly convenient to assemble steering engine

A technology of steering gear and frame, which is applied to vehicle parts, transportation and packaging, and substructure, etc. It can solve the problems of unfavorable assembly and low degree of integration, and achieve the effects of easy heat dissipation, high degree of integration, and high assembly efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

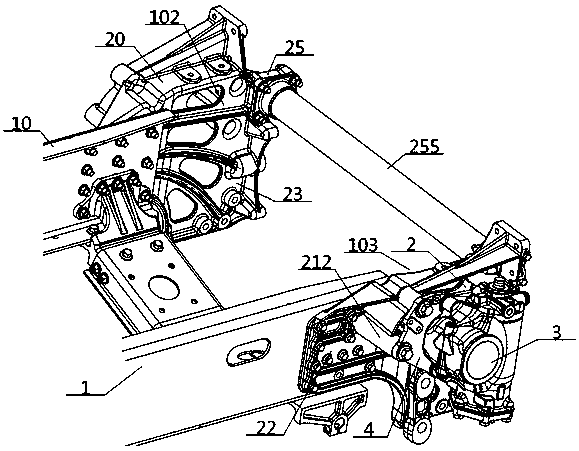

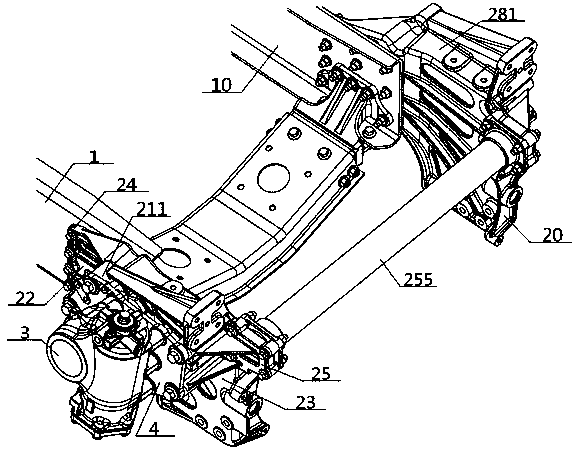

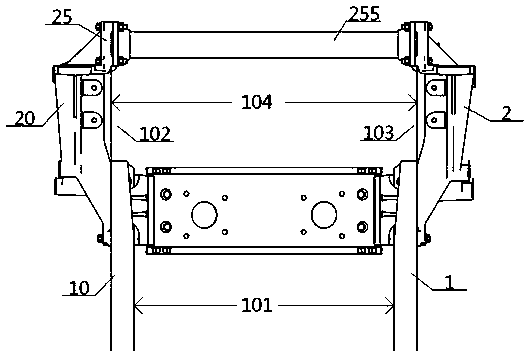

[0063] see figure 1 - Figure 8 , a vehicle frame connection assembly that facilitates the assembly of a steering machine, comprising a right longitudinal beam 1 of a vehicle frame, a left longitudinal beam 10 of a vehicle frame, a large right casting support 2, a large left casting support 20 and a vehicle frame crossbeam 255, the vehicle frame The front end of the left longitudinal beam 10 is connected with one end of the left large casting support 20, the other end of the left large casting support 20 is connected with the other end of the right large casting support 2 through the vehicle frame beam 255, and one end of the right large casting support 2 It is connected with the front end of the right longitudinal beam 1 of the vehicle frame, and the middle part of the right large casting bracket 2 is connected with the steering gear 3 through the steering gear bracket 4, and the right large casting bracket 2 is located on the right longitudinal beam 1 of the vehicle frame an...

Embodiment 2

[0066] Basic content is the same as embodiment 1, the difference is:

[0067] Described casting machine is connected with the bottom end of left upper casting pillar 211, left lower casting pillar 212, right upper casting pillar 213, right lower casting pillar 214 from plate 23, left upper casting pillar 211, left lower casting pillar 212, right upper casting pillar 213, right The tops of the lower casting pillars 214 are all connected with the steering gear bracket 4; Pillar connection hole 215, on the steering gear bracket 4, the position outside the connection of the steering gear bracket 4 and the pillar connecting hole 215 is connected to the steering gear 3; the distance between the upper left casting pillar 211 and the upper right casting pillar 213, and The distance between the lower left casting pillar 212 and the lower right casting pillar 214 is greater than the distance between the upper left casting pillar 211 and the lower left casting pillar 212 and the distance...

Embodiment 3

[0069] Basic content is the same as embodiment 2, the difference is:

[0070] Described steering frame support 4 comprises machine frame plate body 41 and the output shaft hole 42 that offers on it, frame machine connection hole 43, frame frame connection hole 44, and described frame frame connection hole 44 comprises left upper frame hole 441, left lower frame Frame hole 442, right upper frame hole 443 and right lower frame hole 444, described left upper frame hole 441 is correspondingly connected with left upper casting pillar 211, left lower frame hole 442 is correspondingly connected with left lower casting pillar 212, right upper frame hole 443 It is correspondingly connected with the upper right casting pillar 213, and the lower right frame hole 444 is correspondingly connected with the lower right casting pillar 214; the distance between the left upper frame hole 441 and the right upper frame hole 443 is the upper hole distance 445, and the left lower frame hole 442, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com