Top unloading device for spraying

A technology of unloading device and spraying mechanism, applied in the direction of spraying device, etc., can solve the problems of inconvenient double-sided painting operation and poor operation continuity, and achieve the effect of avoiding dead ends of spraying and ensuring stable connection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

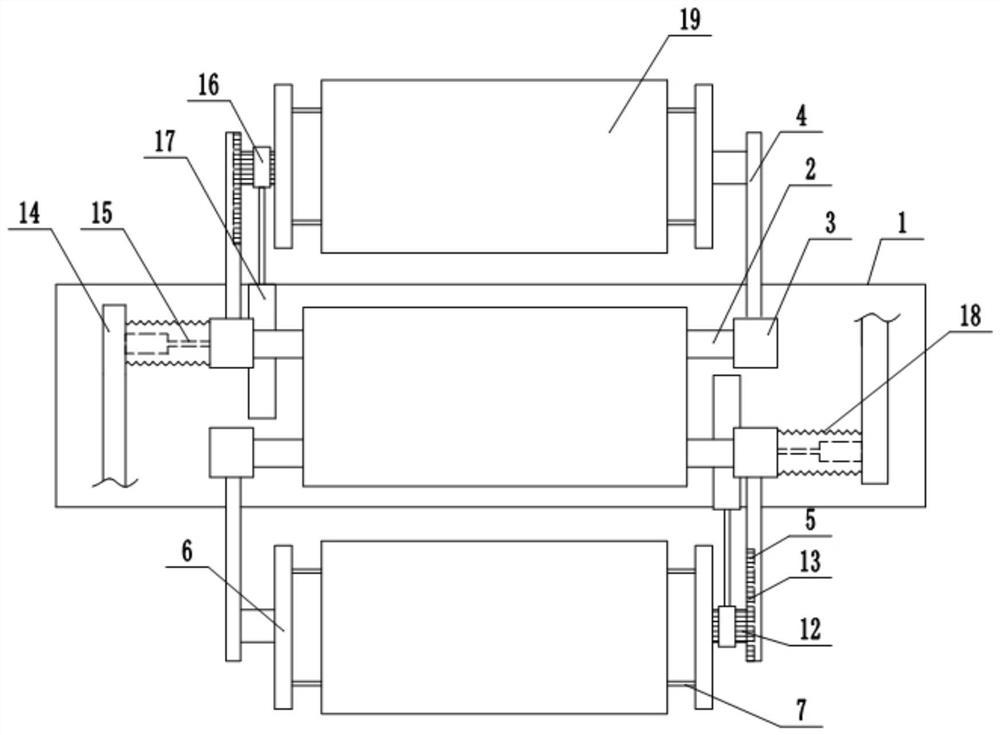

[0033] Embodiment 1 is basically as attached figure 1 As shown: the upper and unloading device for spraying includes a frame, and the upper part of the frame is fixedly connected with a spraying mechanism. The spraying mechanism includes a spraying cover with the opening facing downwards, and a spray nozzle for spraying paint on the door panel 19 is connected horizontally in the spraying cover. The spray head is arranged downwards, and the spray head communicates with a high-pressure paint box (not shown in the figure) through a conduit. There is a support platform 1 fixed on the frame under the spray head, and two parallel support seats 2 are connected horizontally on the support platform 1, and the left and right ends of the support seat 2 are fixedly connected with the connecting seat 3 to support The left and right sides of seat 2 are all provided with connecting platform 14 that is fixedly connected on the supporting platform 1, and connecting platform 14 is all fixedly c...

Embodiment 2

[0044] like image 3 , Figure 4 As shown, the only difference between this embodiment and Embodiment 1 is that in this embodiment, the adjustment assembly includes an overturning shaft 8 fixed on the overturning arm 6, and an overturning gear is affixed outside the overturning shaft 8 through a one-way bearing. 12. The overturning gear 12 is coaxially fixed with a slider 9, the slider 9 is movably connected in the support groove 5, and the end of the support arm 4 away from the support base 2 is fixedly connected with a section of overturning rack 13 that can mesh with the overturning gear 12.

[0045] During use, when the second driving cylinder 17 on the lower side pulls the turning shaft 8 to move towards the direction close to the spray head, the slider 9 slides along the support groove 5 at this time; 17 When the turning shaft 8 is pushed to move away from the nozzle, the slider 9 on the turning shaft 8 moves down along the support groove 5. When the turning gear 12 con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com