High-temperature and high-pressure reaction kettle with controllable volume and pressure

A high temperature and high pressure, reaction kettle technology, applied in pressure vessels/vacuum vessels, pressure vessels used in chemical processes, etc., can solve the problems of difficult cleaning of equipment, easy gas leakage, and high equipment requirements, so as to alleviate the change with temperature and improve the Initial value, cost reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

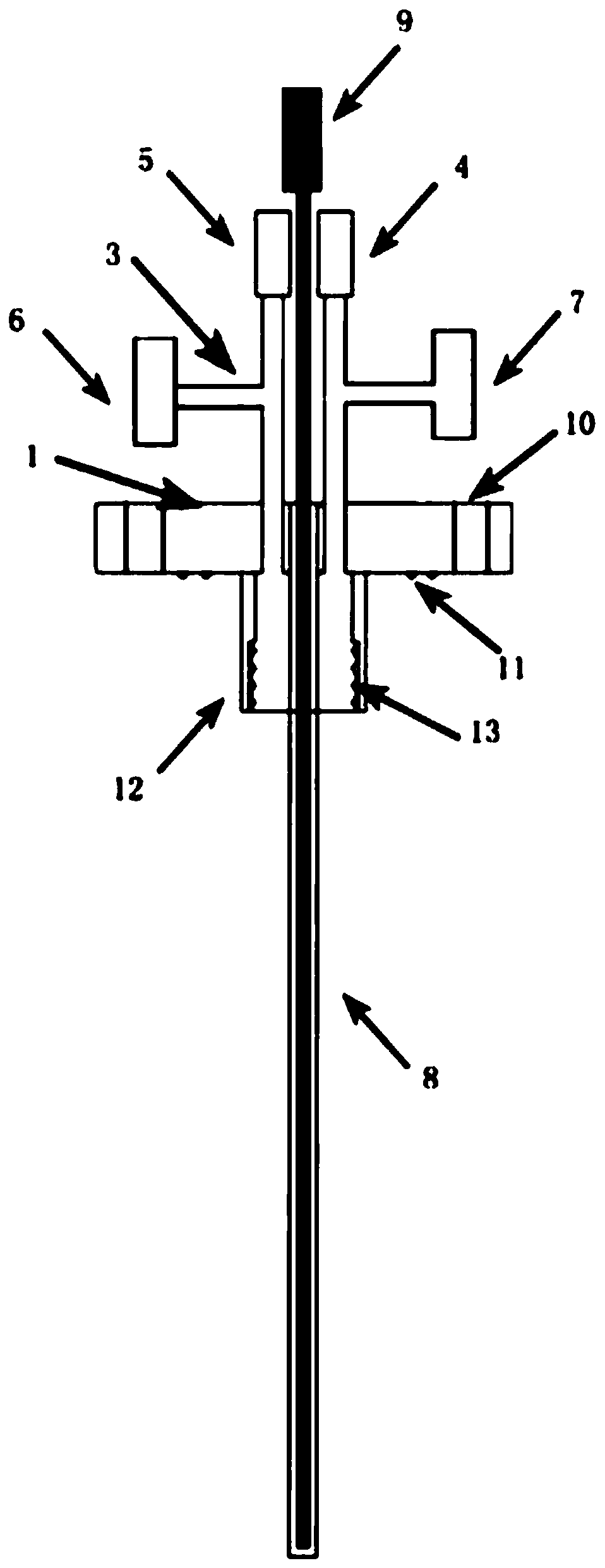

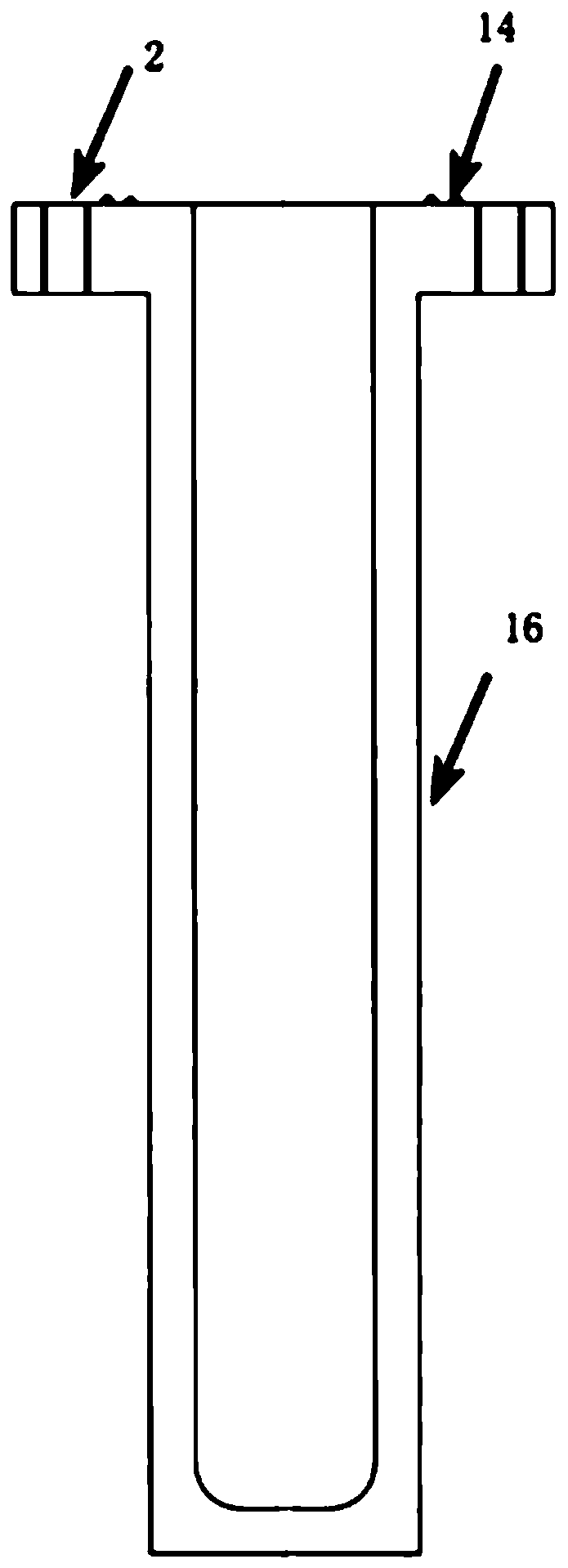

[0035] like figure 1 , figure 2 As shown, a high-temperature and high-pressure reactor with controllable volume and pressure includes a reactor, and the reactor includes a reactor cover 1, a reactor body 16 arranged at the lower end of the reactor cover 1, and a reactor body that penetrates from the reactor cover 1 upper end. To the temperature measuring conduit 8 in the inner cavity of the reactor body 16, the thermocouple 9 is inserted into the temperature measuring conduit 8 to measure the temperature at the bottom of the reactor body, thereby measuring the real-time temperature of the sample in the reactor, and connecting the thermocouple 9 to the signal output device, The temperature signal is output through the signal transmission equipment, which can be used for data analysis to realize the detection of the initial temperature in the kettle and the temperature during the reaction process, so as to meet the actual use requirements;

[0036] A plurality of metal pipes 3...

Embodiment 2

[0040] On the basis of embodiment 1, the different distinguishing features from embodiment 1 are: as Figure 5 As shown, the reaction kettle cover 1 is sequentially provided with a first expansion boss 12 and a first volume modulation assembly that fit into the inner cavity of the reaction kettle body 16, and the first expansion boss 12 is connected with the first volume modulation assembly. The assembly is fixedly arranged through a detachable connection; the first volume adjustment assembly includes a metal filler 29 and an external thread 28 arranged on the upper end of the metal filler 29, and the inner wall of the lower end of the first expansion boss 12 cooperates with the external thread 28. Thread 13, align the external thread 28 with the internal thread 13, and rotate and fix the first volume adjustment assembly on the lower end of the first expansion boss 12. The detachable first volume adjustment assembly can be composed of multiple sections. For the reaction kettle ...

Embodiment 3

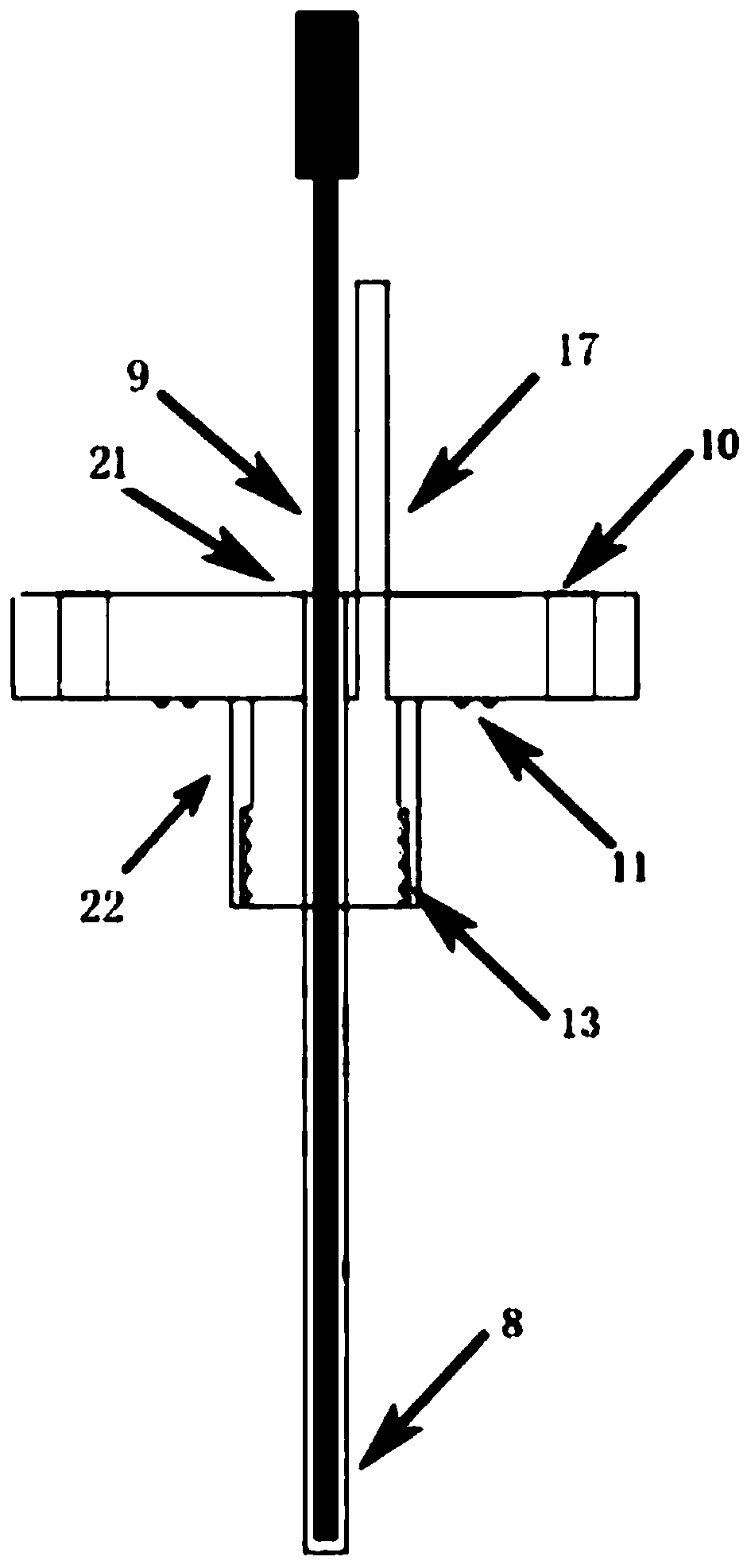

[0043] On the basis of embodiment 1, the different distinguishing features from embodiment 1 are: as image 3 , Figure 4 As shown, one side of the reaction kettle is additionally connected with an expansion kettle, and the expansion kettle includes an expansion kettle cover 21, an expansion kettle body 27 arranged at the lower end of the expansion kettle cover 21, and penetrates from the upper end of the expansion kettle cover 21 to the expansion kettle body 27 The temperature measuring conduit 8 in the inner cavity, the thermocouple 9 is inserted into the temperature measuring conduit 8; it is used to measure the temperature at the bottom of the expansion kettle, so as to measure the real-time temperature of the sample in the expansion kettle, connect the thermocouple 9 to the signal output device, and the temperature signal passes through The output of the signal transmission equipment can be used for data analysis to realize the detection of the initial temperature in the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com