A tower anti-drop equipment installation robot and installation method

A technology for equipment installation and robotics, applied in life-saving equipment, overhead line/cable equipment, safety belts, etc., can solve the problems of low efficiency and difficult installation of temporary anti-fall equipment, so as to improve safety, improve safety protection performance, The effect of reducing labor costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

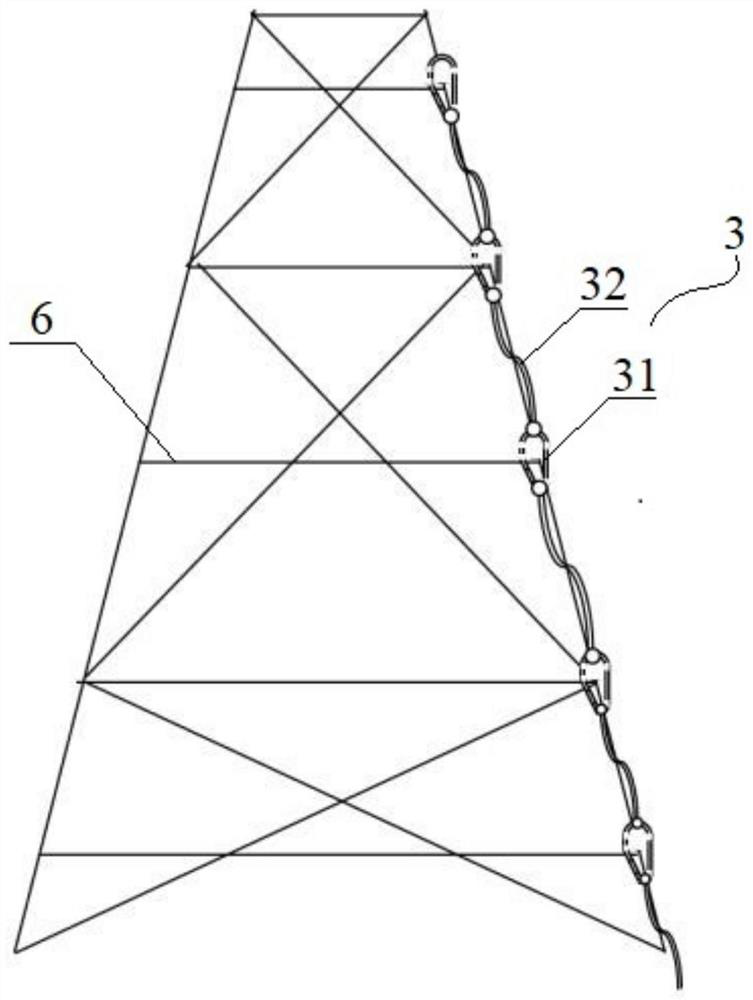

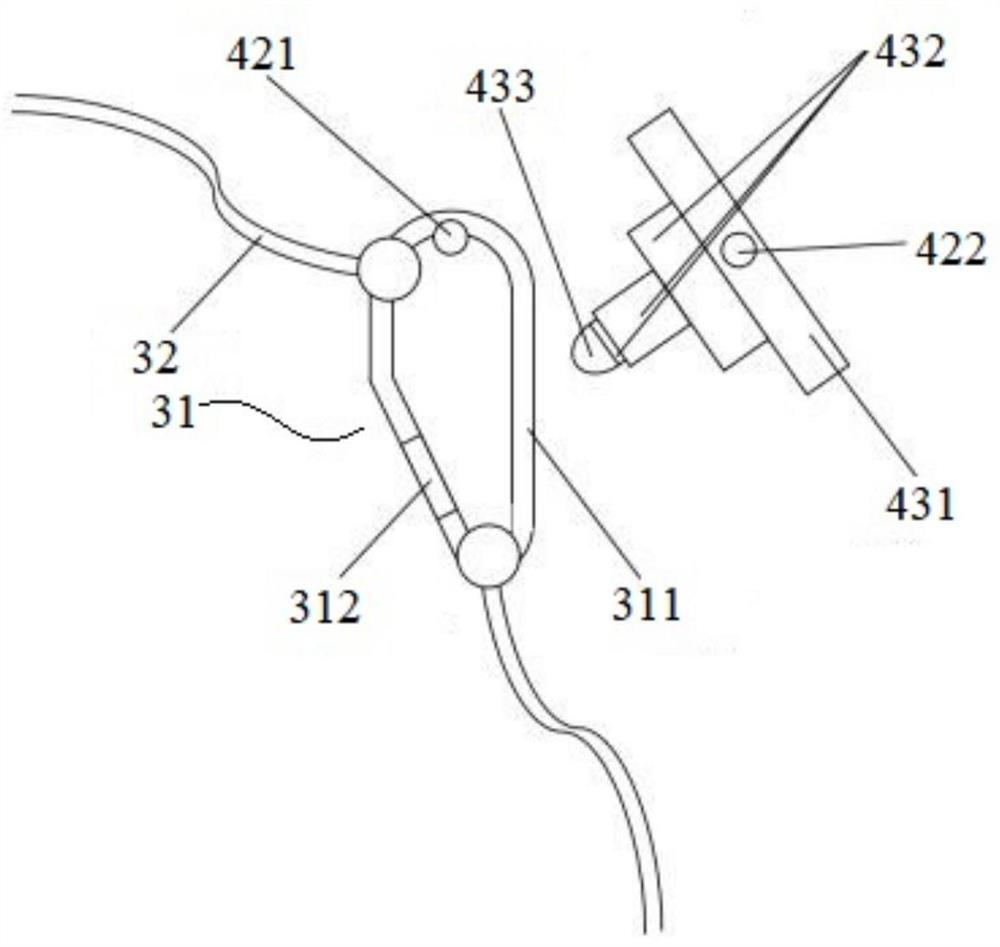

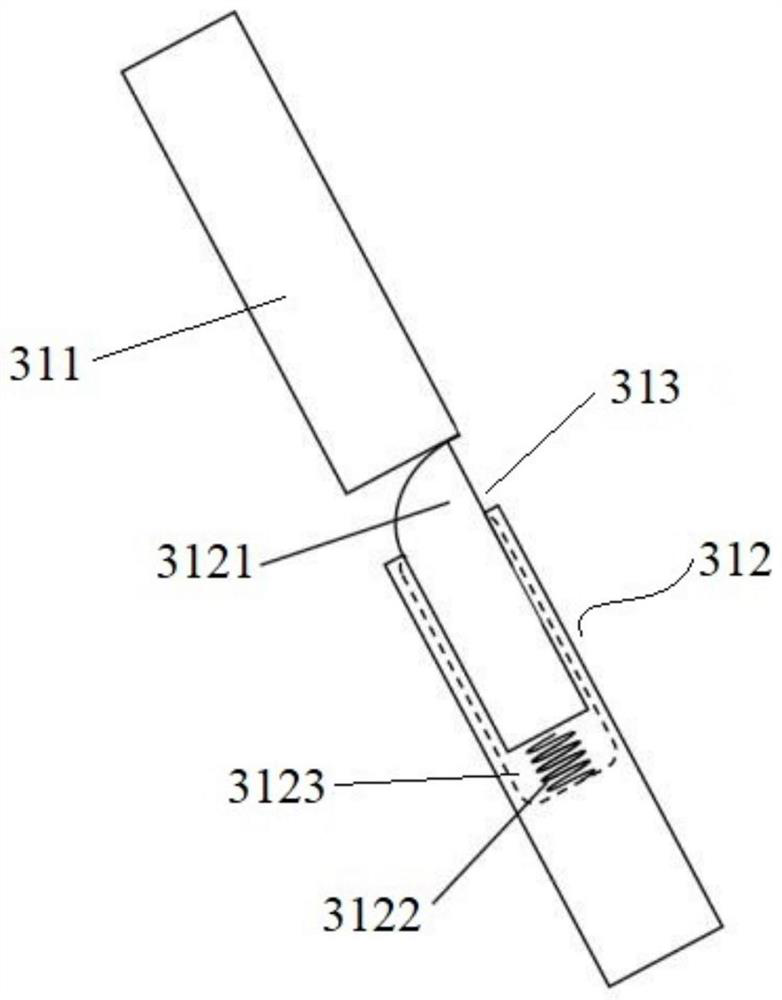

[0043] This embodiment provides a tower anti-drop equipment installation robot, which is used to Figure 1A-Figure 1C The fall arrest device 3 shown is mounted on a pole 6 . Such as figure 2 As shown, the installation robot includes: an environment perception unit 11 , a central control unit 12 , a drive control unit 13 and a fall prevention device installation unit 14 . Wherein, the environment sensing unit 11 , the drive control unit 13 and the anti-fall equipment installation unit 14 are all coupled with the central control unit 12 .

[0044] Wherein, the environment perception unit 11 is used for collecting environment data of the installation robot, and sending the environment data to the central control unit 12 . Here, the environment sensing unit 11 includes at least one image acquisition device 111, the image acquisition device 111 is used to collect the surrounding images of the installed robot, and recognize the surrounding images to obtain the surrounding environm...

Embodiment 2

[0063] An embodiment of the present invention provides a method for installing a tower anti-falling device, which is executed by the central control unit in the installation robot in Embodiment 1 above, and what has already been described will not be repeated here. Such as Image 6 As shown, the method includes the following steps:

[0064] Step S601: Obtain the environment data of the installation robot through the environment perception unit in the installation robot of the tower anti-fall equipment.

[0065] Step S602: Generate a climbing control instruction and an installation control instruction according to the environment data. Here, the climbing structure in the installation robot climbs the pole tower under the control of the climbing control command, and the installation mechanism arranged on the installation robot installs the anti-falling equipment on the pole tower under the control of the installation control command.

[0066] Here, it is also possible to first...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com