A connected pulsating heat pipe cooling device for electronic components

A technology of electronic components and pulsating heat pipes, which is applied to electrical components, electric solid devices, semiconductor devices, etc., can solve the complex structure of air-cooled radiators and water-cooled radiators, the lack of a good connection structure for heat dissipation bases, and the heat dissipation of pulsating heat pipes. Slow and other problems, to achieve the effect of speeding up the heat loss, speeding up the heat loss, and improving the heat dissipation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

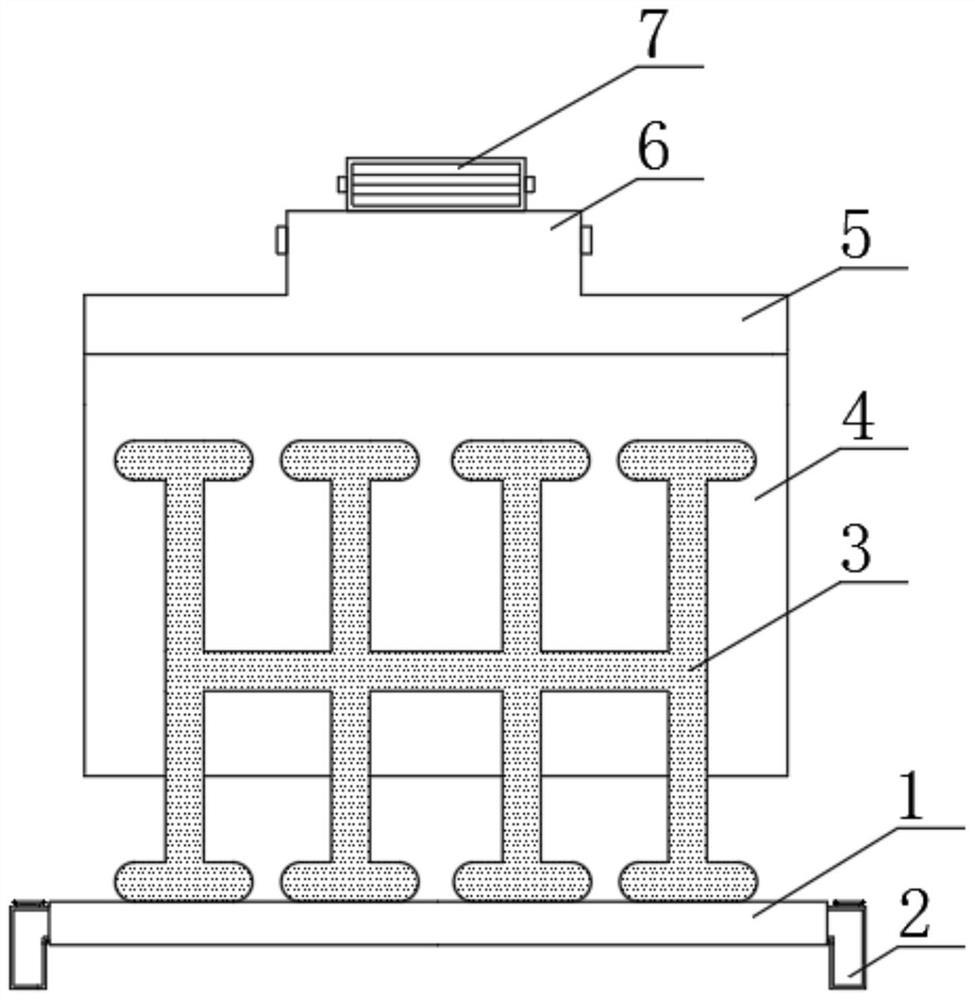

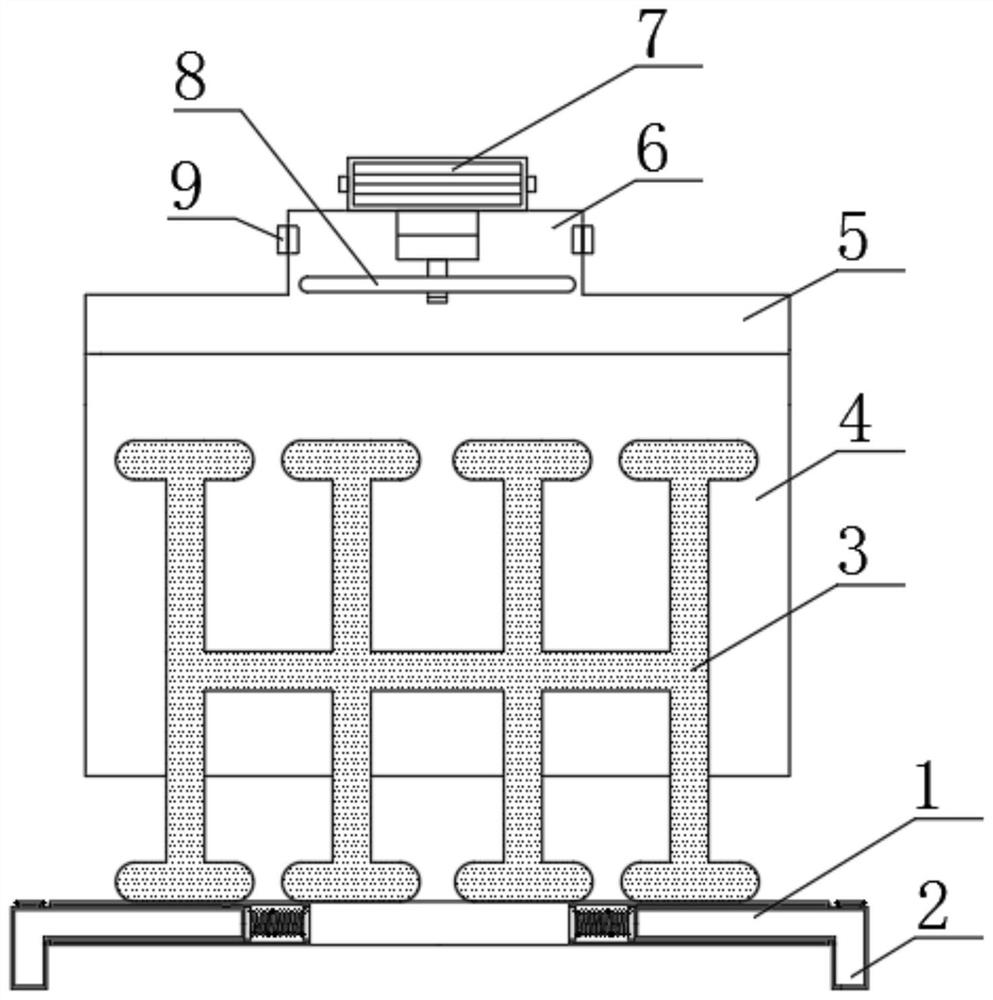

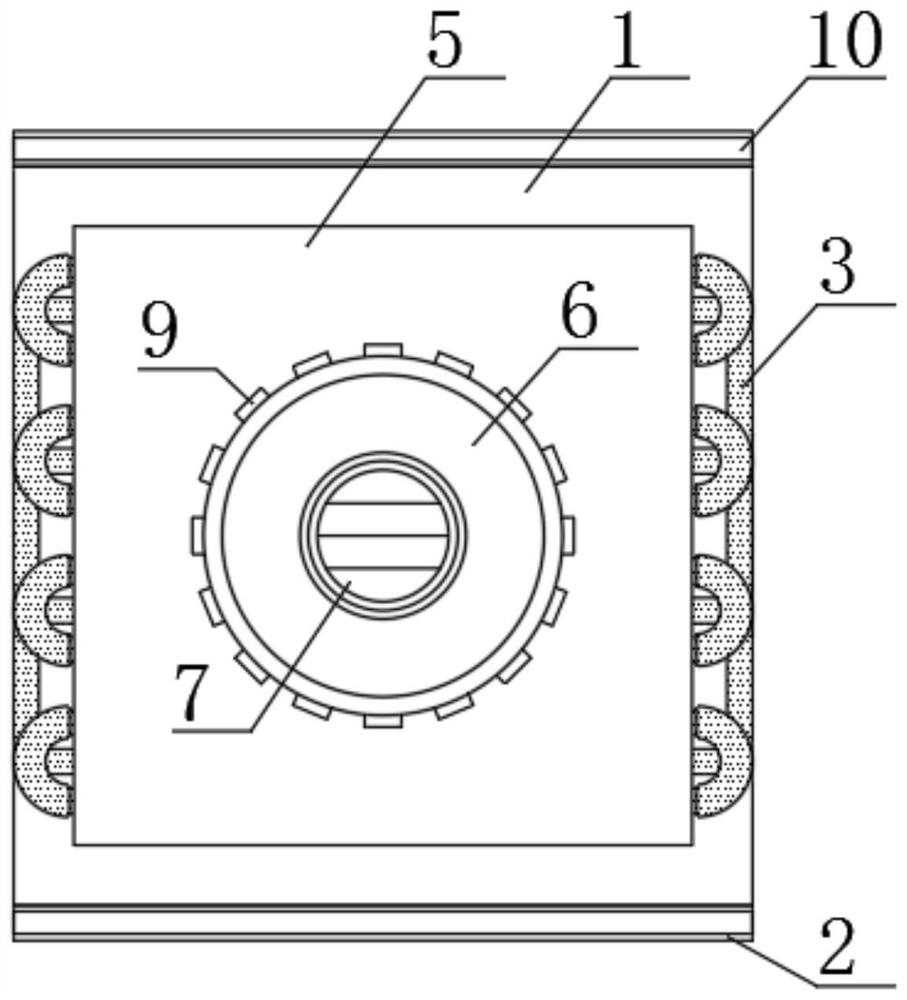

[0022] see Figure 1-Figure 6 , the present invention provides the following technical solutions: a connected pulsating heat pipe heat dissipation device for electronic components, including a heat dissipation base 1, a movable splint 2, a connected pulsating heat pipe 3, heat dissipation fins 4, a wind gathering cover 5, and an air supply box 6 With the electric motor 7, the inner two sides of the cooling base 1 are provided with movable grooves 11, the inner side of the movable groove 11 is provided with movable splints 2, and the inner other side of the movable groove 11 is provided with springs 12, and the top of the cooling base 1 A connected pulsating heat pipe 3 composed of several connected straight pipes and elbows arranged in an equal or staggered manner is provided. The upper end of the connected pulsating heat pipe 3 is provided with a number of uniformly arranged cooling fins 4. Above the connected pulsating heat pipe 3 The upper end of the heat dissipation fin 4 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com