Thermal efficiency correcting method adopted when gas-fired condensing boiler water inlet temperature deviates from designed value

A technology for condensing boilers and inlet water temperature, applied in fluid heaters, lighting and heating equipment, etc., can solve problems such as the impact of energy efficiency testing of new products of condensing boilers, improve test methods, promote energy saving potential, and reduce measurement uncertainty degree of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

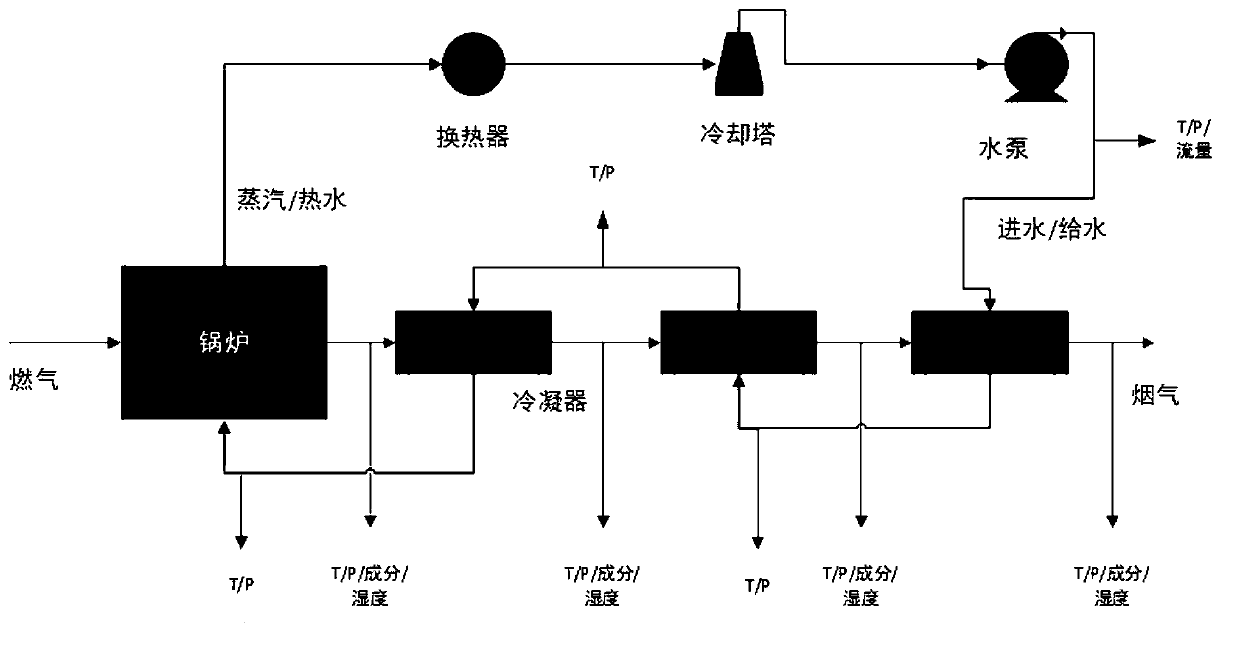

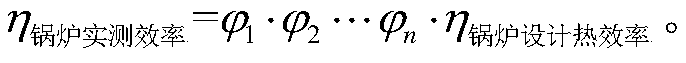

[0022] Specific implementation mode one: see figure 1 This embodiment will be described. A method for correcting thermal efficiency of a gas-fired condensing boiler in which the inlet water temperature deviates from the design value described in this embodiment, the specific steps are as follows:

[0023] Step 1: Obtain different water supply temperature conditions of 10°C, 20°C, 30°C, 40°C, 50°C, 60°C, 70°C, 80°C, 90°C, 100°C, 104°C (20°C, 60°C, 104°C ℃ is the typical design feed water temperature), not limited to the above temperature, other feed water temperatures are also possible, the measured thermal efficiency of the boiler (excluding the condenser), the measured thermal efficiency is under different load conditions (30% ~ 110%, at least 5 load conditions);

[0024] Step 2: Calculate the boiler thermal efficiency ratio under different feedwater temperatures, different load boiler efficiency and design conditions Draw a table of ratios;

[0025] Step 3: Obtain diffe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com