Method for reducing clearance of roller thrust bearing

A thrust bearing and roll technology, applied to the rigid brackets, bearing components, shafts and bearings of bearing components, etc., can solve the damage to the steel plate scraping frame and equipment, the instability of the rolling mill roll system, and the large amount of movement of the roll in the bearing seat. and other problems, to save the cost of spare parts, reduce the bad shape, and improve the performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

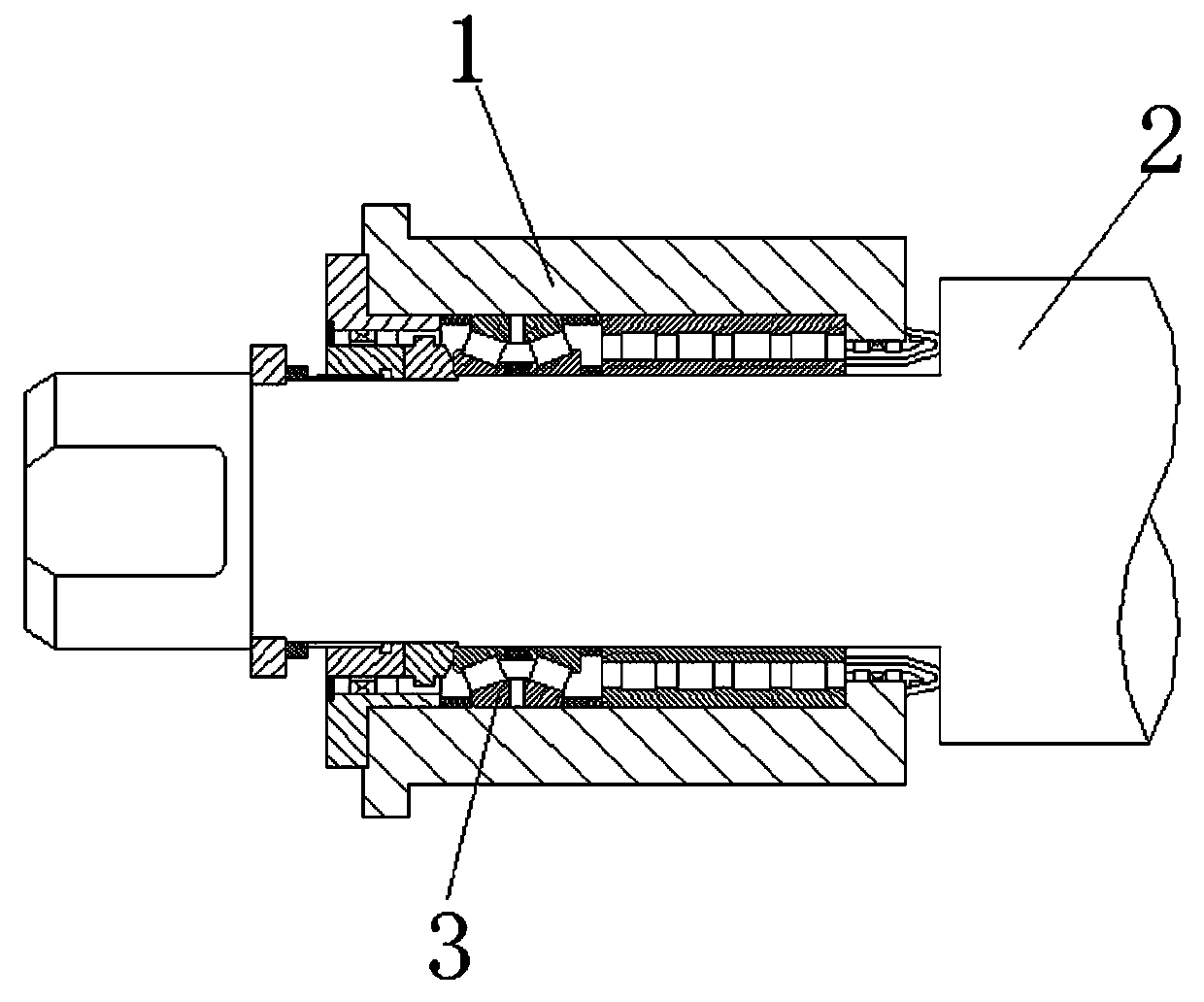

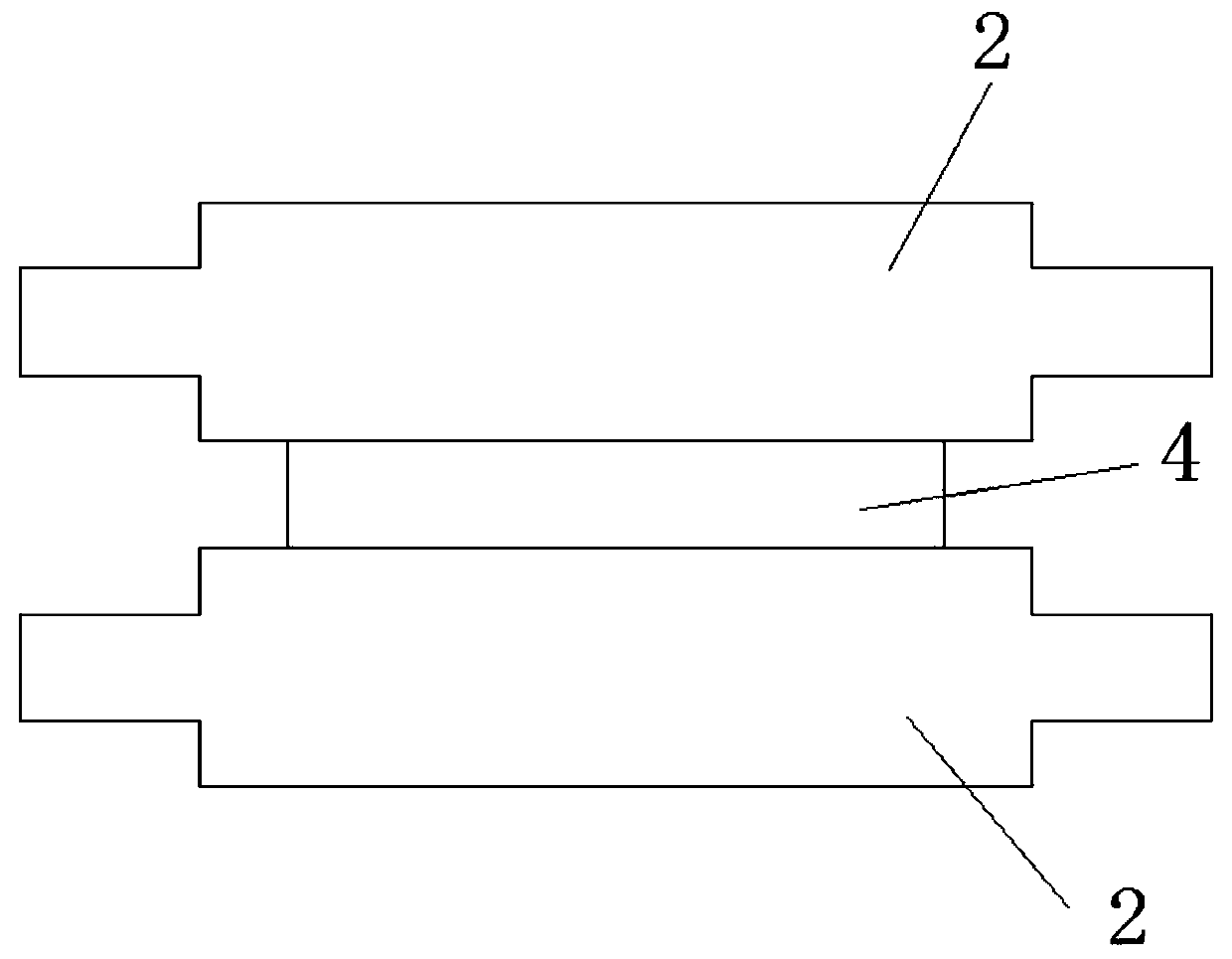

[0023] Such as Figure 1 to Figure 5 As shown, a method for reducing the clearance of the roll thrust bearing is characterized in that it includes:

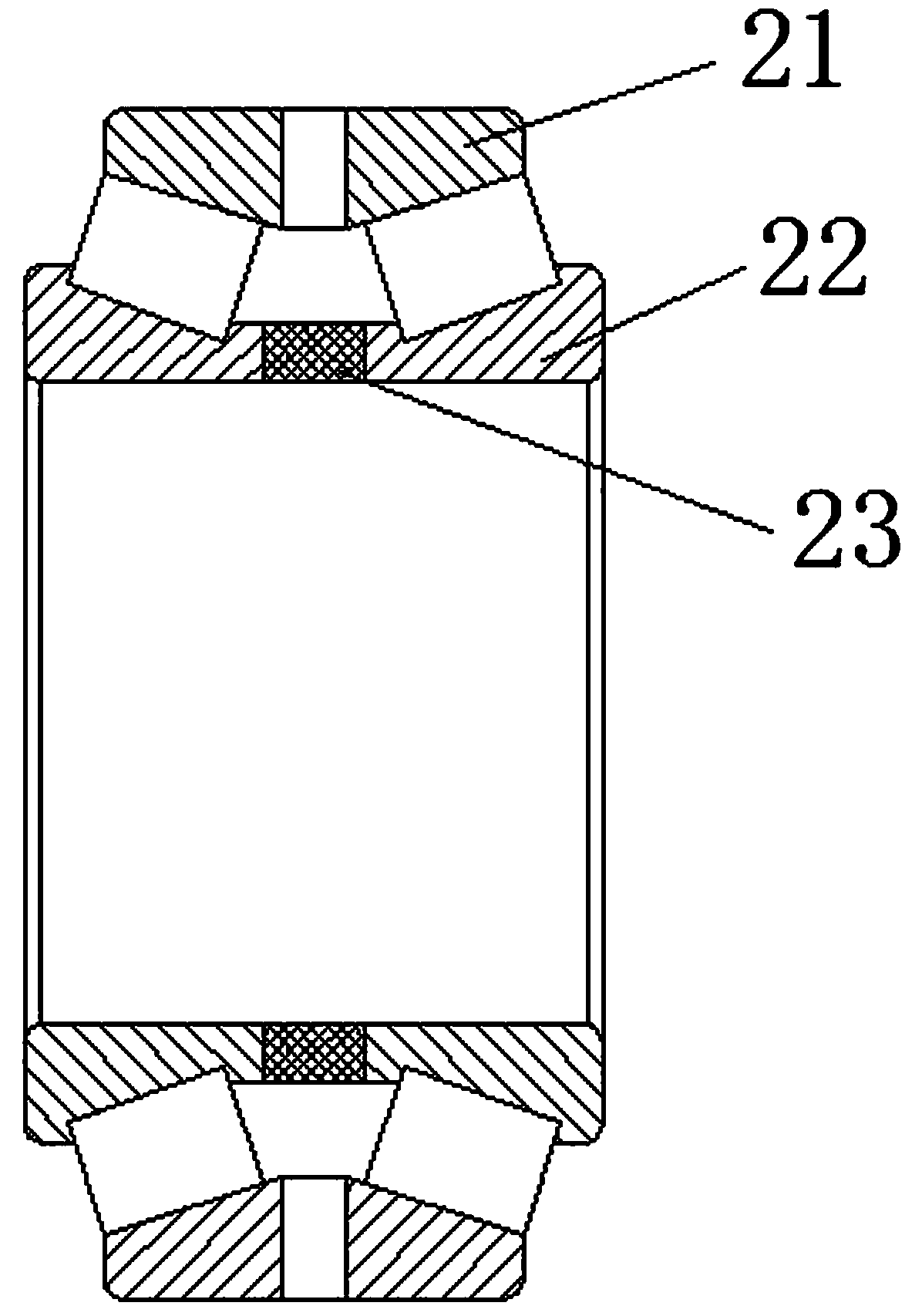

[0024] According to the movement requirement of the roll 2, disassemble the bearing housing 1 that does not meet the movement requirement to take out the thrust bearing 3, take out the two rows of inner rings 22 and spacer rings 23 of the thrust bearing 3 from the outer ring 21, record the interval the width of circle 23 and denoted as A;

[0025] Put the two rows of inner rings 22 back into the outer ring 21, record the gap between the two rows of inner rings 22 and mark it as B;

[0026] According to the instruction manual of the thrust bearing 3, determine the required clearance range of the thrust bearing 3 and denote it as C;

[0027] Grind the spacer ring 23 from width A to width B+C, and put th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com