Fireproof steel structure for a green building

A green building and steel structure technology, applied in building components, building structures, buildings, etc., can solve problems such as general fire performance and achieve high-strength effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

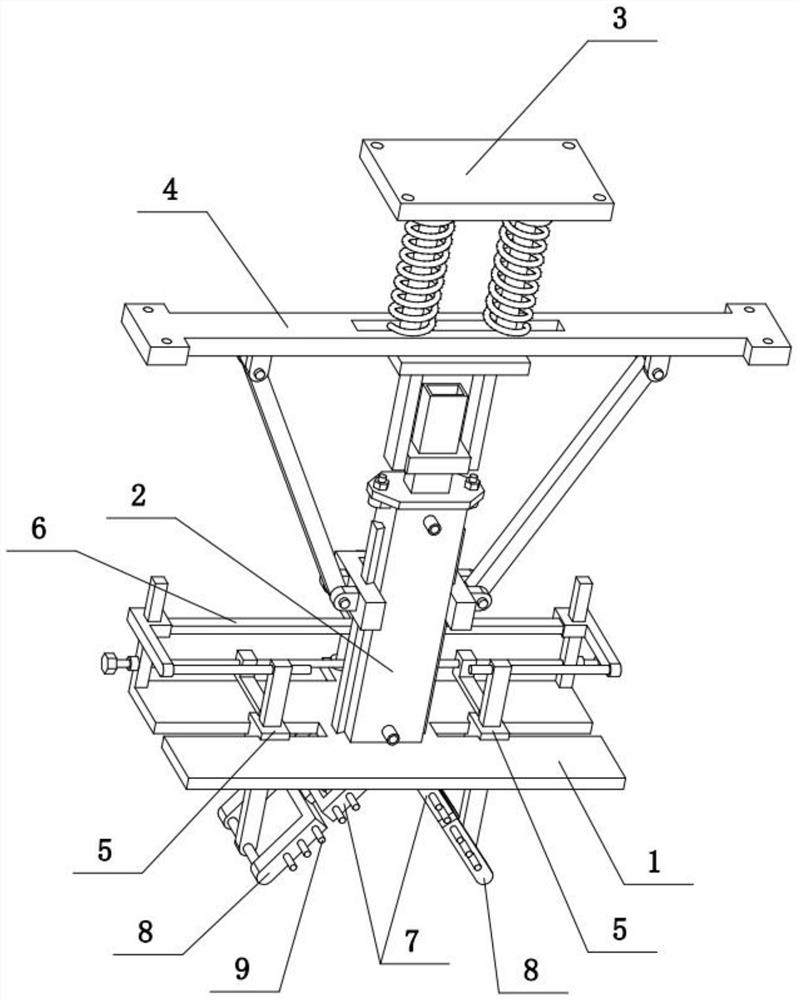

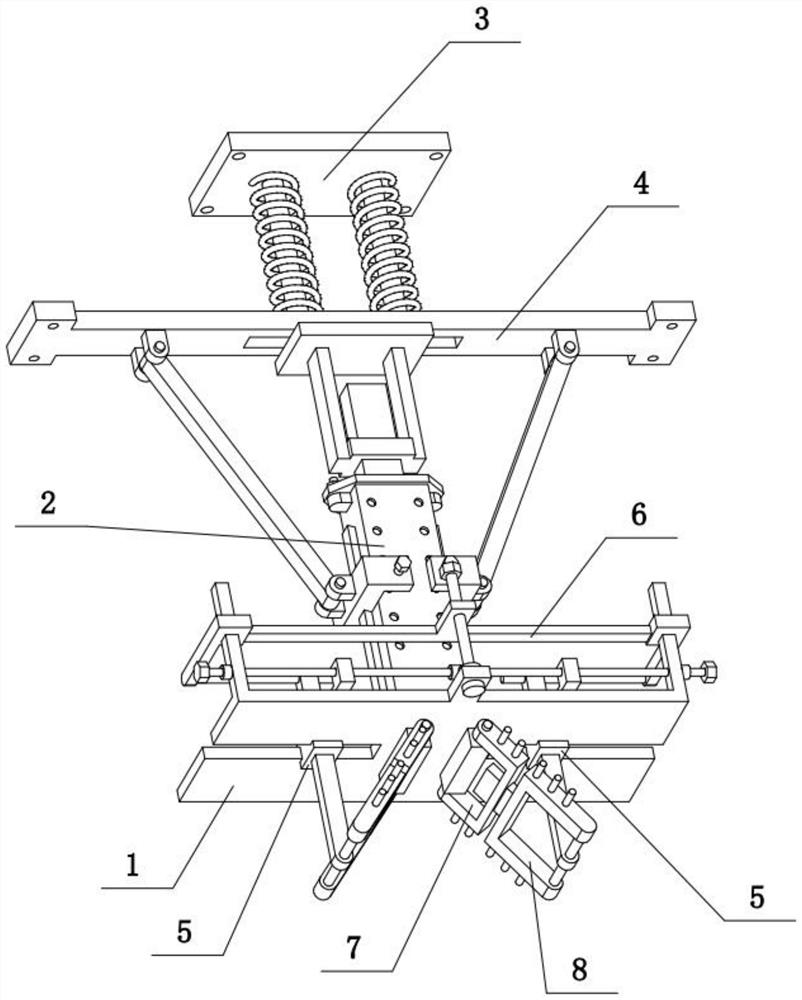

[0033] Combine below Figure 1-11 To illustrate this embodiment, the present invention relates to a steel structure, more specifically a fireproof steel structure for green buildings, including a bottom plate 1, an outer steel cylinder 2, a joint pipe 201, a top cover 203, an inner steel cylinder 204, a threaded Between the short column 205 and the groove 206 between the steel cylinders, the present invention can adjust the temperature of the steel structure, and the steel structure still has relatively high strength when a fire breaks out.

[0034]An outer steel cylinder 2 is fixedly connected to the center of the upper end of the bottom plate 1, the outer steel cylinder 2 is in the shape of a hollow rectangular cylinder, and an inner steel cylinder 204 is fixedly connected to the center of the upper end of the bottom plate 1, and the inner steel cylinder 204 is located on the outer steel cylinder 2. Inside, the steel cylinder groove 206 is formed between the inner steel cyli...

specific Embodiment approach 2

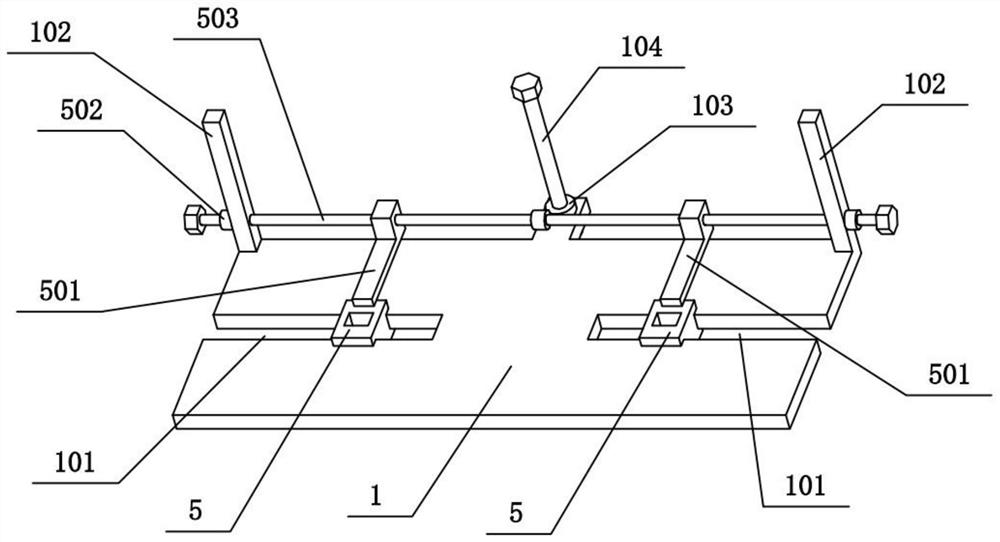

[0036] Combine below Figure 1-11 To illustrate this embodiment, the fire-resistant steel structure for green buildings also includes trapezoidal slide rails 202, round sockets 207, roof beams 4, oblique connecting rods 403, vertical shift seats 404 and inserting screws 405, and the left and right sides of the outer steel cylinder 2 Both sides are provided with trapezoidal slide rails 202, and the two trapezoidal slide rails 202 are slidably connected with a vertical shift seat 404, and the rear ends of the two vertical shift seats 404 are connected with inserting screws 405 by threads. The left and right ends of the side are evenly distributed with a plurality of circular sockets 207 from top to bottom, and two inserting screws 405 are respectively inserted on two of the circular sockets 207, and the left and right ends of the lower side of the roof beam 4 are hingedly connected. There are oblique connecting rods 403, and the lower ends of the two oblique connecting rods 403 ...

specific Embodiment approach 3

[0038] Combine below Figure 1-11 Illustrate this embodiment mode, described green building fireproof steel structure also comprises rainproof roof mounting plate 3, spring cover bar 301, rectangular seat 302, connecting vertical post 303, sliding sleeve 304 and long hole 401, sliding sleeve 304 is connected in sliding The upper end of the inner steel cylinder 204 and the left and right sides of the sliding sleeve 304 are fixedly connected with connecting vertical columns 303, the upper ends of the two connecting vertical columns 303 are fixedly connected with a rectangular seat 302, and the upper ends of the rectangular seat 302 are fixedly connected with two Spring sleeve rod 301, two spring sleeve rods 301 are sleeved with compression springs, the upper ends of the two spring sleeve rods 301 are fixedly connected with a rainproof roof installation plate 3, and the middle position of the roof beam 4 is provided with a long hole 401 , the two spring sleeve rods 301 pass throu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com