Method for determining safe remaining service life of elevator without maintenance

An elevator and maintenance technology, applied in the field of establishment and algorithm innovation, can solve problems such as increasing the risk of elevator safety accidents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0177] Method for determining the safe remaining service life of elevators without maintenance:

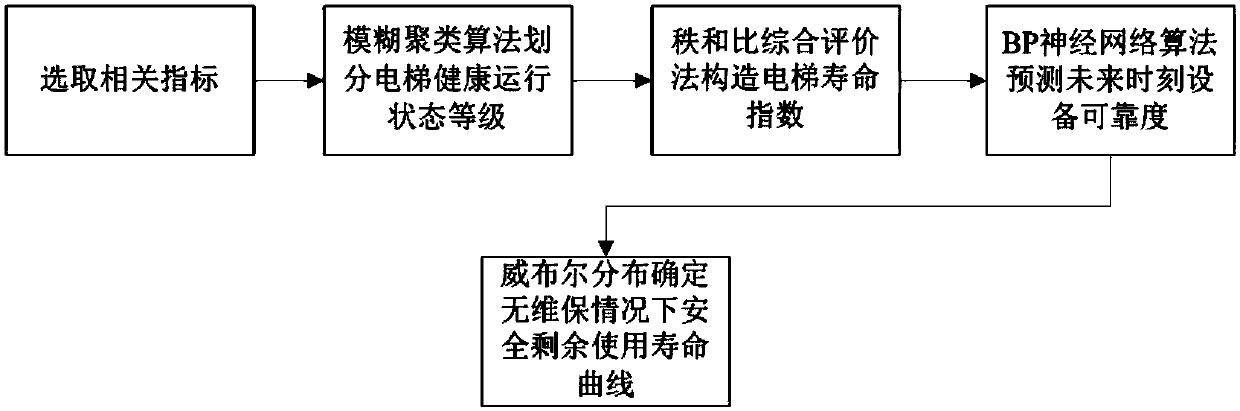

[0178] The performance of each component in the initial operation stage of the elevator equipment is relatively good, and the operating state is relatively stable. Generally speaking, no maintenance is required. However, once the elevator equipment enters the wear-and-tear period, the reliability of the equipment operation will continue to decline with the accumulation of time. When it falls to a specified threshold, it will exceed the safe remaining service life of the elevator, and the first preventive maintenance of the equipment is required. Before the first preventive maintenance, the safe remaining service life model of the elevator without maintenance can be established, and the time interval from the current moment to the first preventive maintenance can be determined. The model creation process is as follows figure 1 As shown: (1) Monitor the elevator operation indicator...

Embodiment 2

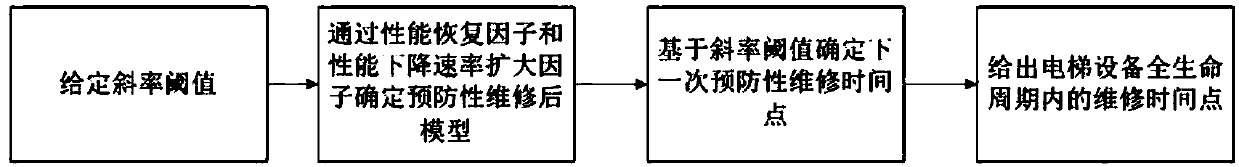

[0245] Method for determining the safe remaining service life of elevators under maintenance conditions:

[0246] The elevator safety remaining service life model in the case of maintenance is to complete the determination of the time interval between two consecutive maintenances on the basis of the established elevator safety remaining service life model in the case of no maintenance The prediction of the elevator performance curve after permanent maintenance, and the determination of the elevator scrapping time and other work. From a theoretical point of view, the influence of maintenance cost and maintenance times on the elevator maintenance time interval and the remaining service life of the elevator is given. In the specific establishment process of the model, the next maintenance time of the elevator is determined by considering the slope of the function, and whether the elevator should be stopped is judged by introducing technical and economic indicators. Flowchart of ...

Embodiment 4

[0290] Model application:

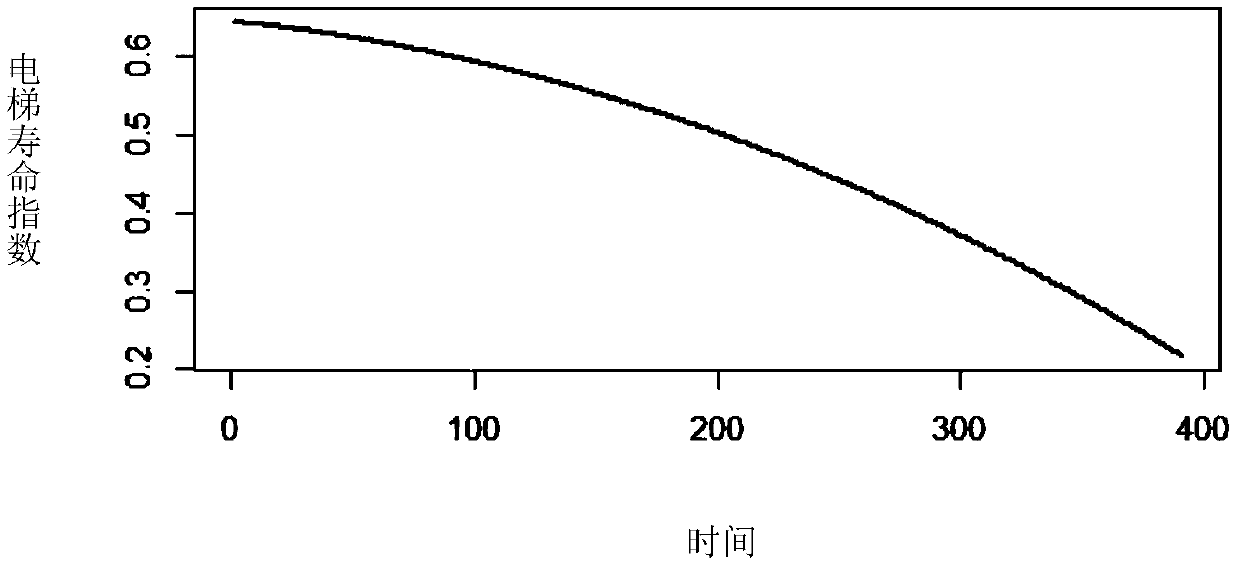

[0291] In order to verify the feasibility of the model, 1000 sample data can be randomly generated based on the normal value range of 17 specific indicators. And assume that the first set of sample data is collected at time 0, and the time interval between two consecutive sets of sample data is 2 hours.

[0292] (1) Data preprocessing and index selection

[0293] In order to avoid the impact of dimensionality on the validity of the model, the original data needs to be preprocessed, that is, each index is dimensionless, and the value of each index is between [0,1]. The degradation function can be introduced here. After converting each index with the degradation function, not only can the data be transformed into [0,1], but they are all positive indicators, that is, the larger the index value, the better the state of the elevator. excellent. The 17 original indicators were transformed into the degree of deterioration according to the type of indica...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com