Brick stack feeding device and unstacker using brick stack feeding device

A technology for destackers and brick stacks, which is applied in the field of depalletizers and brick stack feeding devices, and can solve the problems that it is difficult to ensure good and reliable clamping of multiple groups of fired bricks, and it is easy to affect the smooth clamping of fired bricks.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

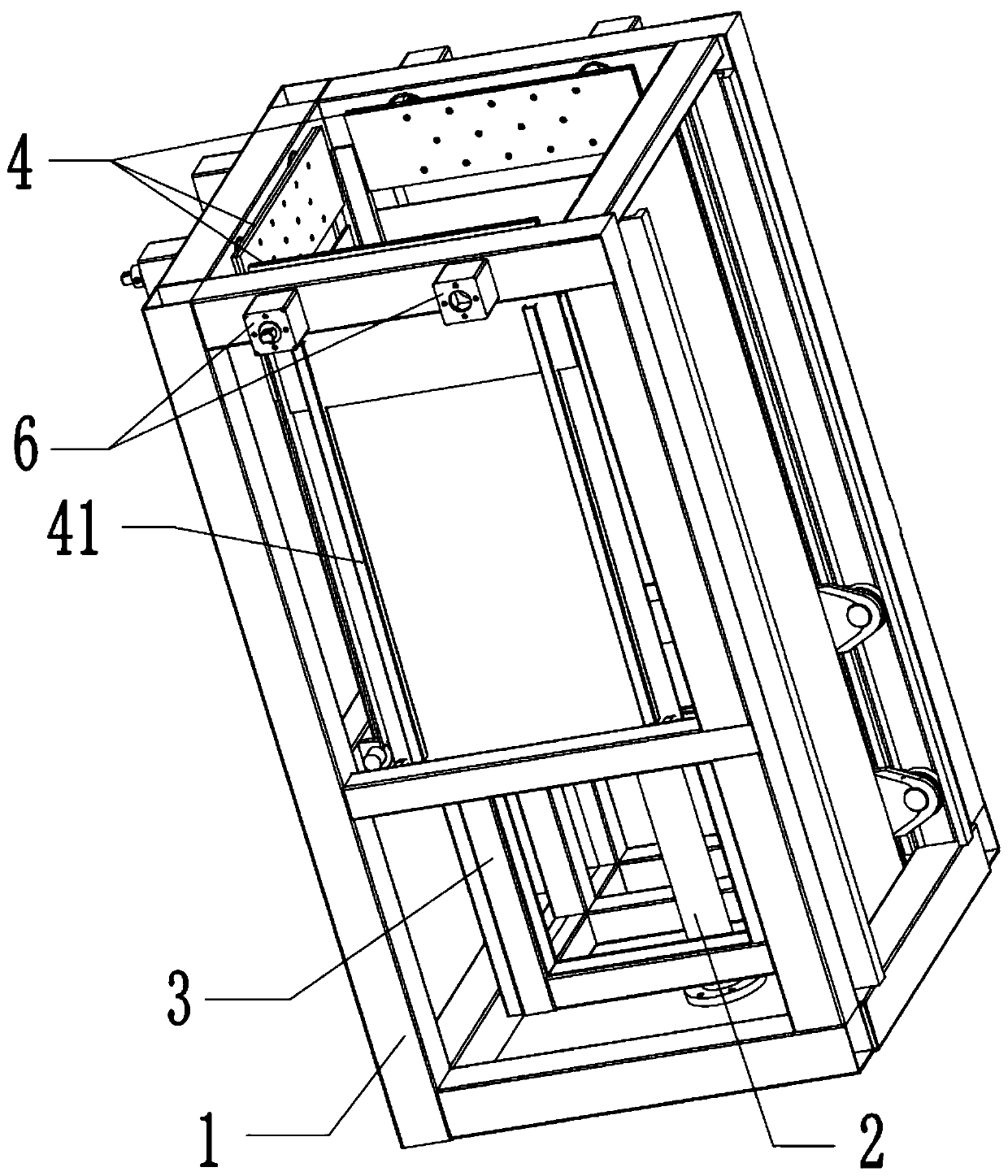

[0042] Such as figure 1 with figure 2Shown, a kind of brick pile feeding device comprises main frame 1, oil cylinder one 2, lifting frame 3 and guide plate group 4, and oil cylinder one 2 is set in main frame 1, and the output end of oil cylinder one 2 is connected lifting frame 3, guides The plate set 4 includes multiple sets of guide plates, which are all obliquely arranged in the main frame 1, and the multiple sets of guide plates form a prism-shaped accommodation cavity with a small top and a large bottom, and the brick stacks are accommodated in the cavity. , the lifting frame 3 is driven up by the oil cylinder 1 on the main frame 1, so that the stack of sintered bricks placed on the lifting frame 3 rises layer by layer to the top of multiple groups of guide plates. Shaped housing cavity structure, which can be used to arrange the piles of fired bricks to be clamped, so as to ensure that the top layer of fired bricks is kept neat when passing through the housing cavity,...

Embodiment 2

[0048] Such as figure 1 with figure 2 As shown, the difference from Embodiment 1 is that, further, the lower ends of multiple groups of guide plates are rotatably connected to the main frame 1, and the guide plates connected to the main frame 1 through the lower ends can be rotated in the uneven brick stack. When placed on the lifting platform, ample space can be opened between multiple sets of guide plates, so that the whole stack of sintered bricks can be completely lowered to the bottom with the lifting frame 3, and then each set of guide plates is rotated, so that the multiple sets of guide plates form an upper small Lower the large housing cavity to ensure that the top layer of sintered bricks remains neat when passing through the housing cavity, so as to be ready for destacking.

[0049] Specifically, a connecting rod is fixed at the lower end of the guide plate, and the mounting seat can be welded and fixed on the main frame 1 .

[0050] Further, stop strips 41 are a...

Embodiment 3

[0053] Such as figure 1 with figure 2 As shown, the difference from Embodiment 1 and Embodiment 2 is that, further, the brick stack feeding device is set to also include a distance adjustment mechanism 6, one end of the distance adjustment mechanism 6 is fixed on the main frame 1, and the distance adjustment The other end of mechanism 6 is fixed on the guide plate.

[0054] Further, the distance adjusting mechanism 6 can be configured as a telescopic cylinder, the telescopic cylinder is fixed on the main frame 1, and the output end of the cylinder rod of the telescopic cylinder is connected to the guide plate, so as to push multiple groups of guide plates to gather or separate from each other.

[0055] Further, the telescopic cylinder can be set as an air cylinder, a hydraulic cylinder or an oil cylinder, and through the cooperation of the telescopic cylinder, multiple sets of guide plates and the structure whose lower end is rotatably connected to the main frame 1, it can m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com