Light artificial board with zig-zag inner core and preparation method thereof

A wood-based panel and glyph technology, which is applied in the direction of manufacturing tools, wooden veneer joints, wood processing appliances, etc., can solve the problems of low cost, large restrictions on reprocessing, and affecting use, etc., and achieve light weight and less material consumption , the effect of large space inside the board

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] Example 1 Zigzag inner core lightweight wood-based panel

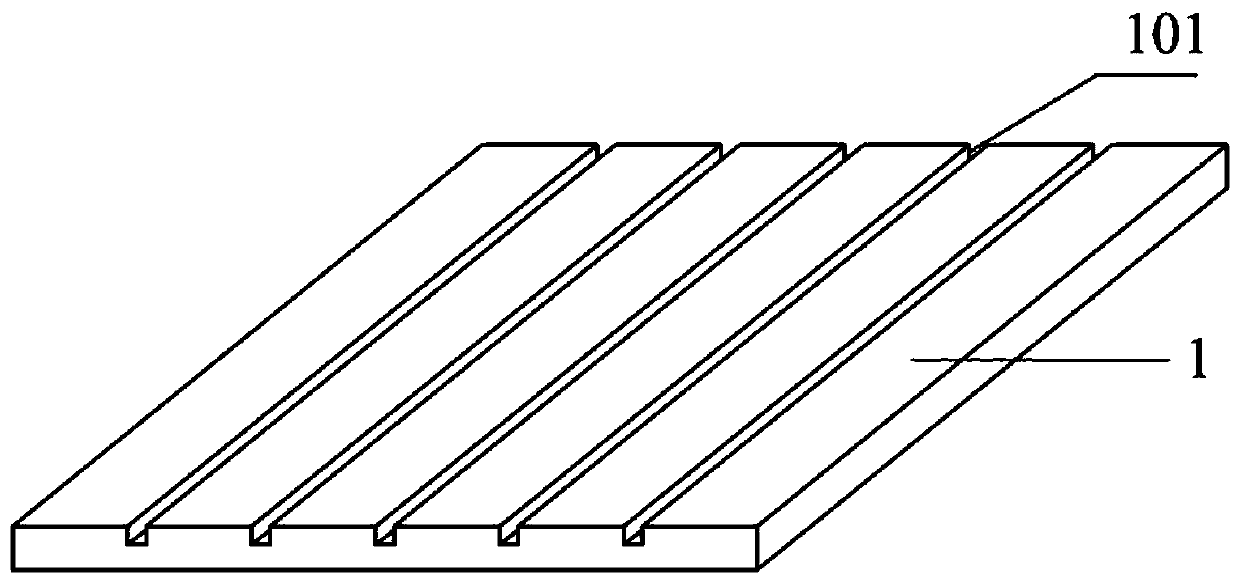

[0042] Such as figure 1 with figure 2 As shown, the zigzag inner core lightweight wood-based panel is composed of a surface panel 1, a vertical partition 2, a support piece 3 and a surrounding panel 4.

[0043] The wood-based panel has two upper and lower surface panels 1, and the distance between the upper and lower two surface panels 1 is 15-600mm. Such as image 3 with Figure 4 As shown, a plurality of parallel shallow grooves 101 are opened on the surface plate 1 , and the cross section of the shallow grooves can be square 101 , trapezoidal 102 or nearly triangular 103 . The distance between two adjacent shallow grooves is 50-600mm. Such as Figure 5 with Image 6 As shown, the two edges of the vertical partition 2 have protrusions 201 that match the shape of the shallow groove, and the protrusions on both sides of the vertical partition are inserted into the shallow groove, and are fixedly connecte...

Embodiment 2

[0047] The preparation of embodiment 2 zigzag inner core lightweight wood-based panel

[0048] Figure 11 Shown is the flow chart for the preparation of the zigzag inner core lightweight wood-based panel described in Example 1. The preparation steps are as follows:

[0049] 1. Plate processing

[0050] (1) Surface processing

[0051] Process the surface board substrate according to the set thickness, width and length. The thickness of the surface plate is 2mm-12mm.

[0052] (2) Vertical clapboard processing

[0053] Process wood / bamboo slats with the same length, width and thickness as vertical partitions, the length of the vertical partitions is the same as the width of the front panel, and the width of the vertical partition is the same as the distance between the wood-based panel and the lower panel. Such as Image 6 As shown, a convex part 201 with a trapezoidal 202 or nearly triangular 201 cross-section can be machined on the two edges of the vertical partition 2 a...

Embodiment 3

[0076] The fir hollow door panel of embodiment 3 zigzag inner core

[0077] Using fir boards and fir strips, hollow boards were prepared according to the method in Example 2.

[0078] The upper and lower panels are made of fir boards, the size is: 200cm×100cm×0.5cm, the density ρ=0.5g / cm 3 .

[0079] The fir strips are made into vertical partitions, the size is: 200cm×5cm×1cm.

[0080] The fir strips are made into supporting pieces, and the size is: 42.42cm×5cm×0.5cm.

[0081] The fir strips are made into hoardings, the lengths are 200.5cm and 100.5cm, the width is 6cm, and the thickness is 0.5cm.

[0082] The fir board is made into a vertical support board, and the size is: 200cm×5cm×7cm.

[0083] Such as Figure 12 As shown, three vertical clapboards 2 are set between the upper and lower table plates, and the distance between the vertical clapboards is 30cm. The support pieces 3 are arranged in a zigzag shape between the vertical partitions 2, and the most end support ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com