Preparation process and production line of low caffeine instant tea

A low-caffeine, preparation technology, applied in tea, tea extraction, tea alkali content reduction, etc., can solve the problems of increasing the prevalence of rheumatoid arthritis, stimulating the central nervous system, increasing blood pressure, etc., to improve the adsorption effect, The effect of expanding the application area and improving the heat dissipation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] Specific embodiments of the present invention will be described below with reference to the accompanying drawings.

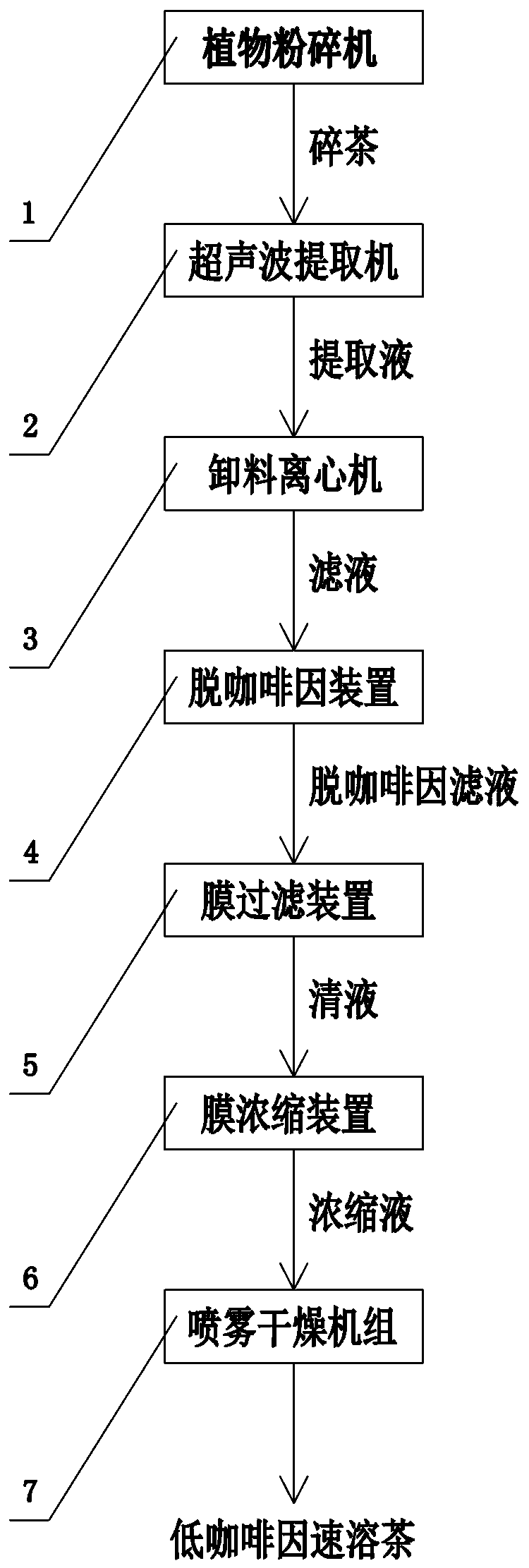

[0041] refer to figure 1 . A preparation process of low-caffeine instant tea, comprising the following steps:

[0042] 1) crushing: the tea leaves to be processed are crushed by the plant pulverizer 1 to obtain crushed tea; specifically in this embodiment, the tea leaves are Tieguanyin tea leaves;

[0043] 2) Water extraction: put the crushed tea and water into the ultrasonic extractor 2 according to the ratio of 1:20 for extraction to obtain the extract;

[0044] 3) Filtration: transport the extract to the discharge centrifuge 3 for filtration to obtain the filtrate;

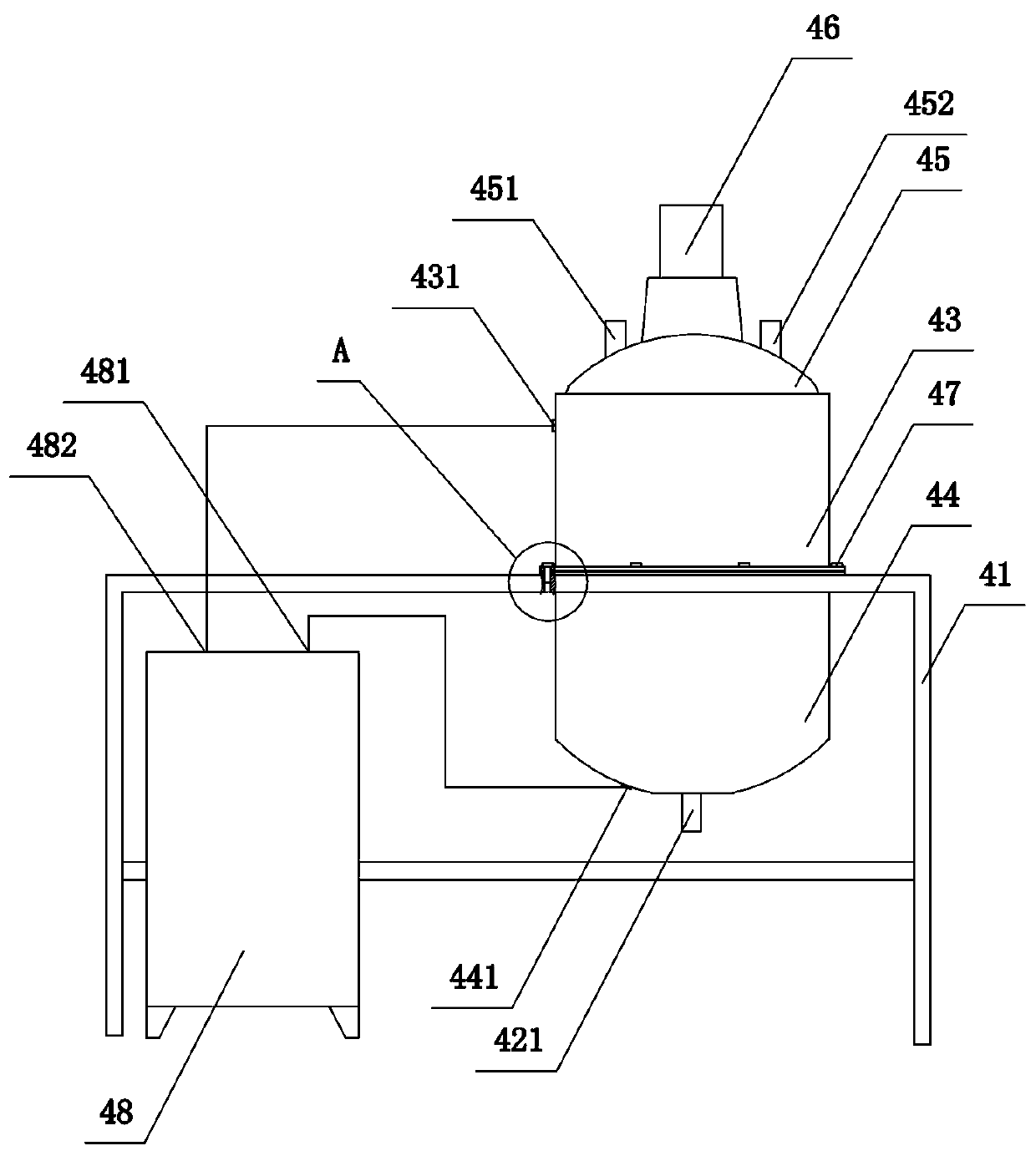

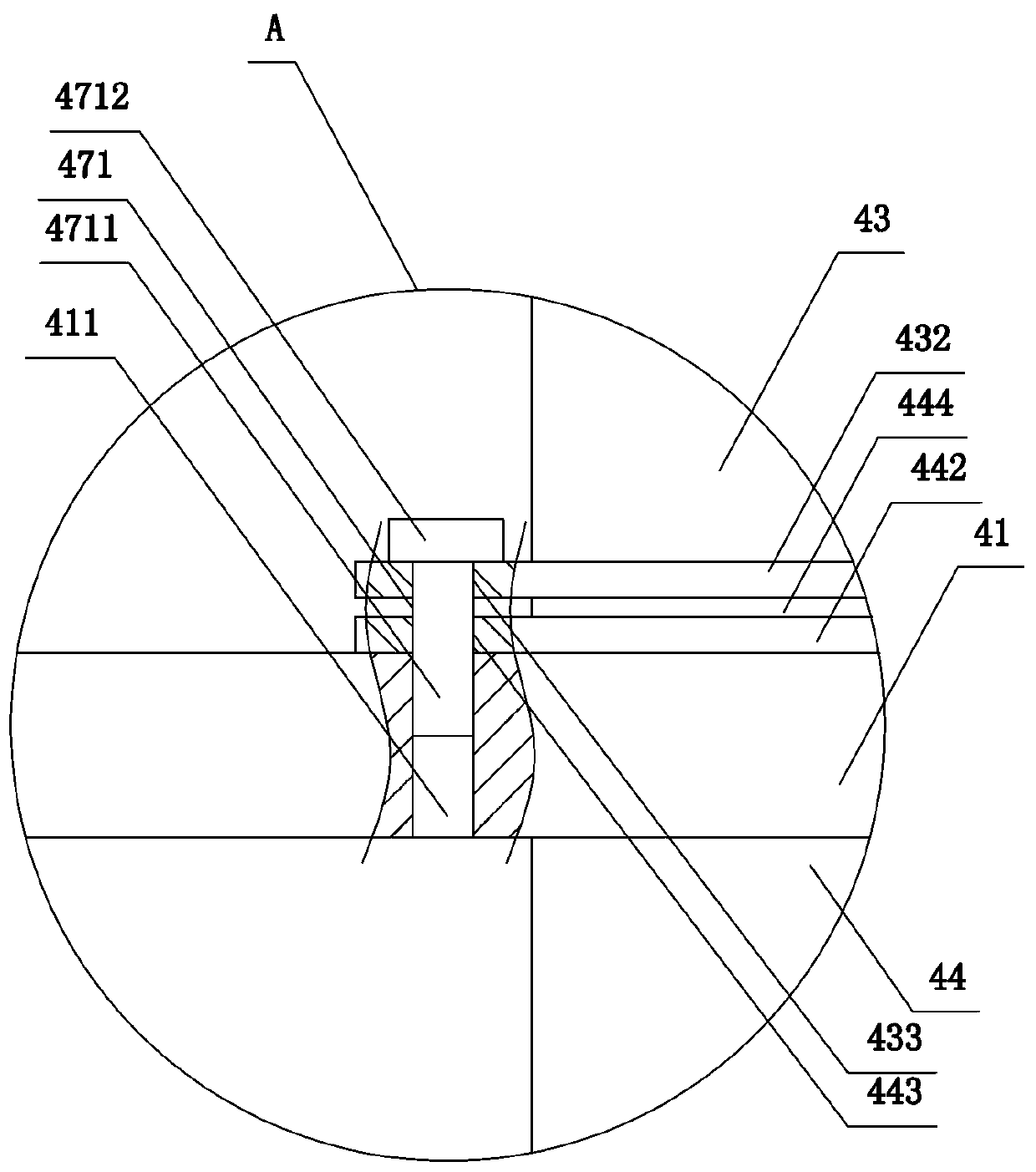

[0045] 4) Decaffeination: The filtrate and the caffeine adsorbent are transported to the decaffeination device 4 for decaffeination to obtain the decaffeinated filtrate; wherein the caffeine adsorbent is a macroporous resin, and the macroporous resin has an The adsorption of caffeine i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com