An electromagnetic energy harvester

An energy harvester and electromagnetic technology, applied in the direction of electric components, electromechanical devices, electrical components, etc., can solve the problems of large energy loss, reduced output power, and limited application range, so as to increase output power, reduce friction loss, and apply wide range of effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

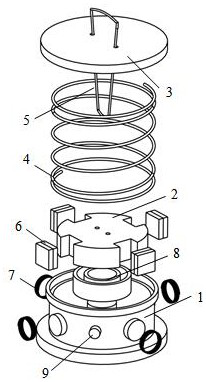

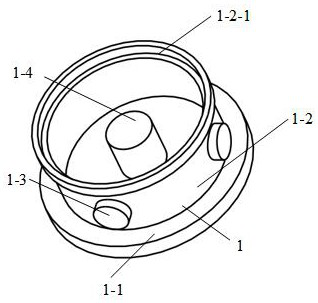

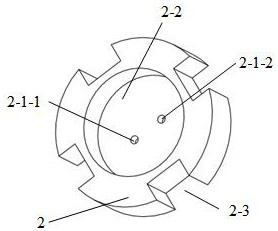

[0031] Such as figure 1 , Figure 5 As shown, an electromagnetic energy harvester at least includes a base 1, a rotor 2, a top cover 3, a spring 4, a cord 5, four magnets 6, four coils 7, a radial bearing 8, and a ferromagnetic patch 9 ; The base 1 includes a cylinder bottom 1-1, a cylinder 1-2, several cylindrical protrusions 1-3, a cylinder shaft 1-4, and a first blind hole 1-2-1; the cylinder 1- 2. perpendicular to the cylinder bottom 1-1 and coaxial with the cylinder bottom 1-1; the cylinder shaft 1-4 is cylindrical, and the cylinder shaft 1-4 is vertically and fixedly connected to the center of the base 1; The cylindrical protrusion 1-3 is fixed on the outer cylindrical surface of the cylinder 1-2, and the cylindrical protrusion 1-3 is evenly distributed on the surface of the cylinder 1-2; the first blind hole 1 -2-1 is on the surface of the cylinder 1-2 and is coaxial with the cylinder 1-2; the lower end of the spring 4 is embedded in the base 1; the upper end of the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com