Finite control set model predictive contour control method suitable for double-axial or tri-axial feed driving system

A finite control set and feed-driven technology, applied in the general control system, digital control, program control, etc., can solve problems such as inability to achieve advance control, unpredictable cross-coupling gain, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

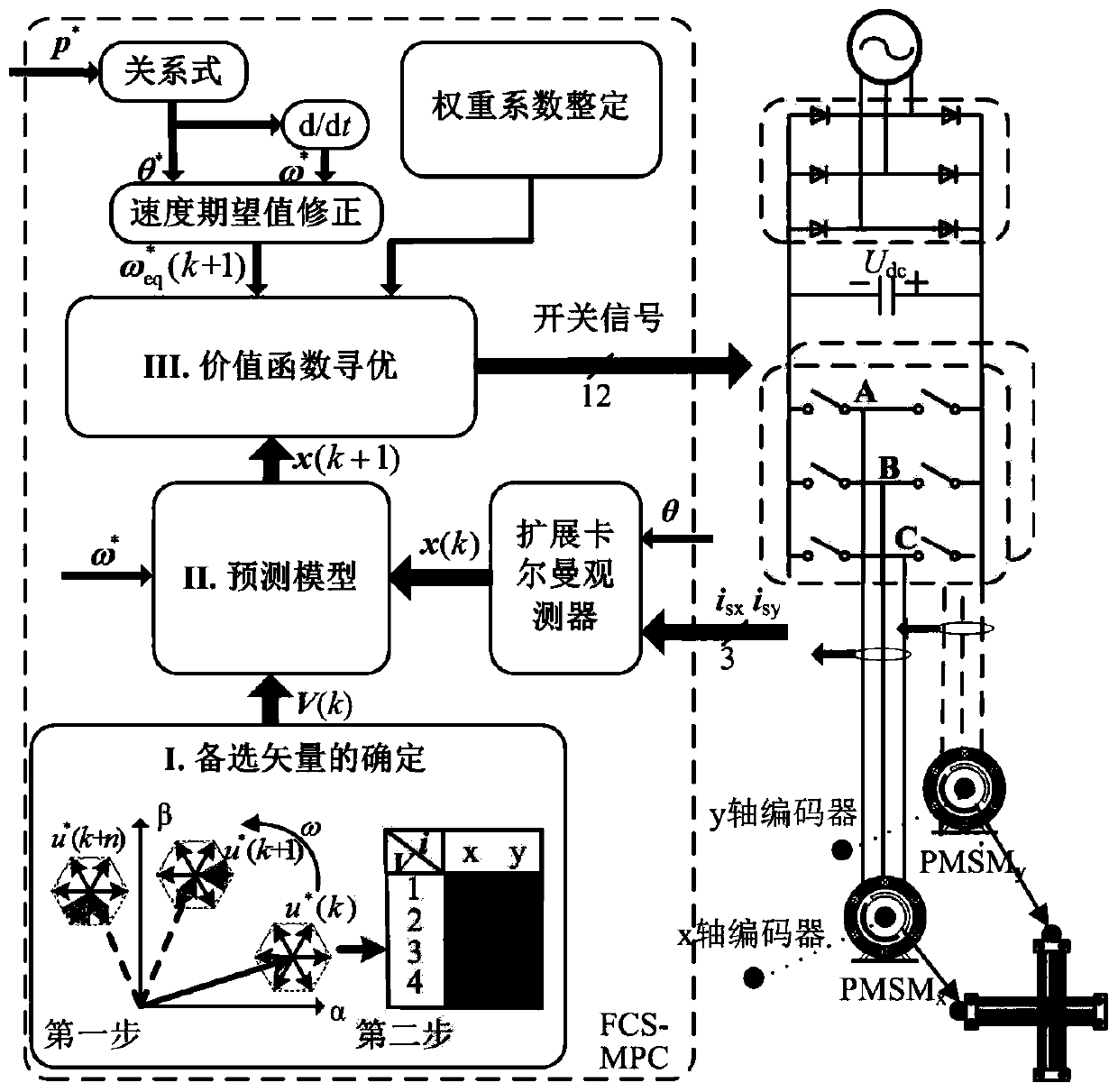

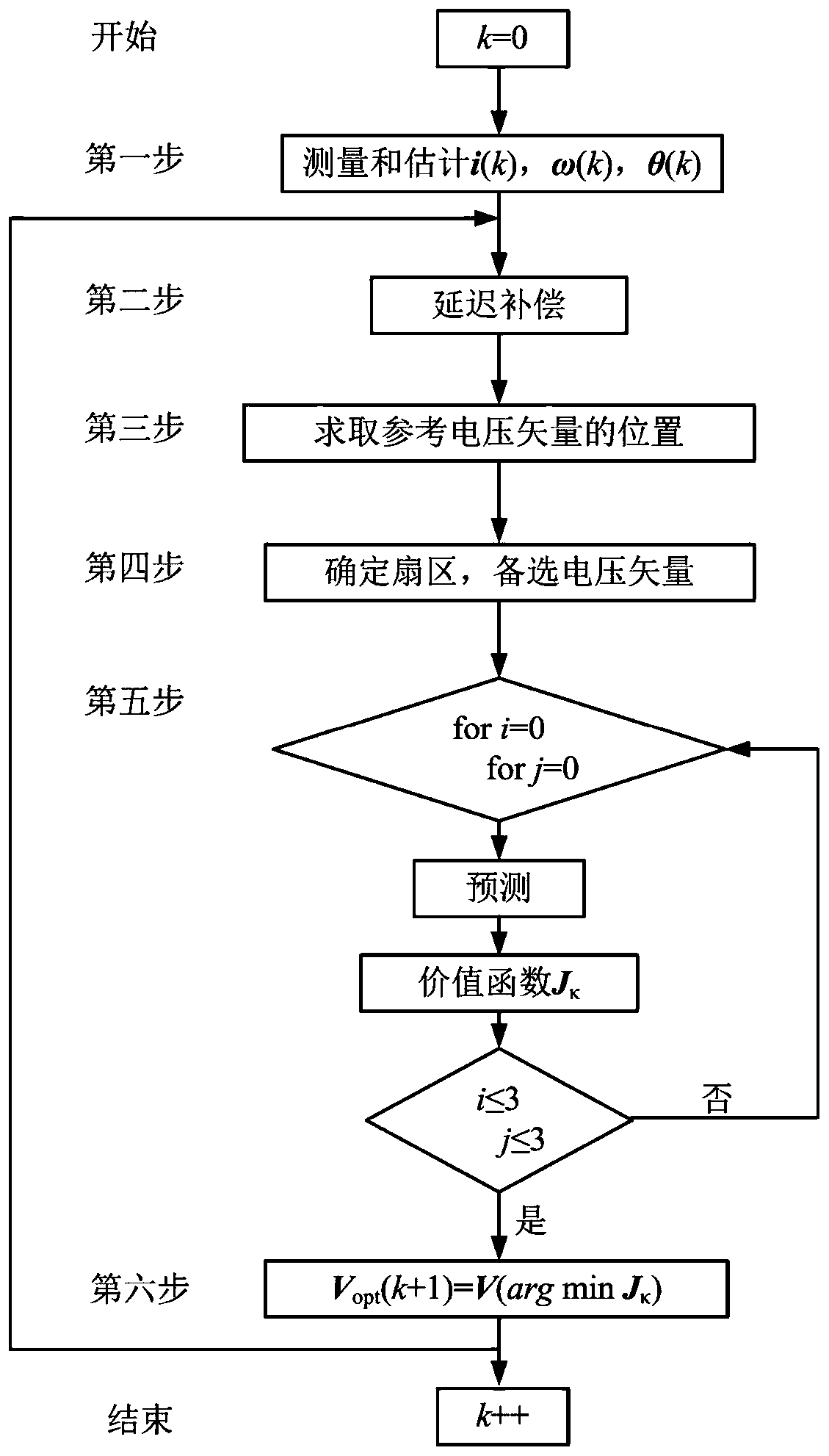

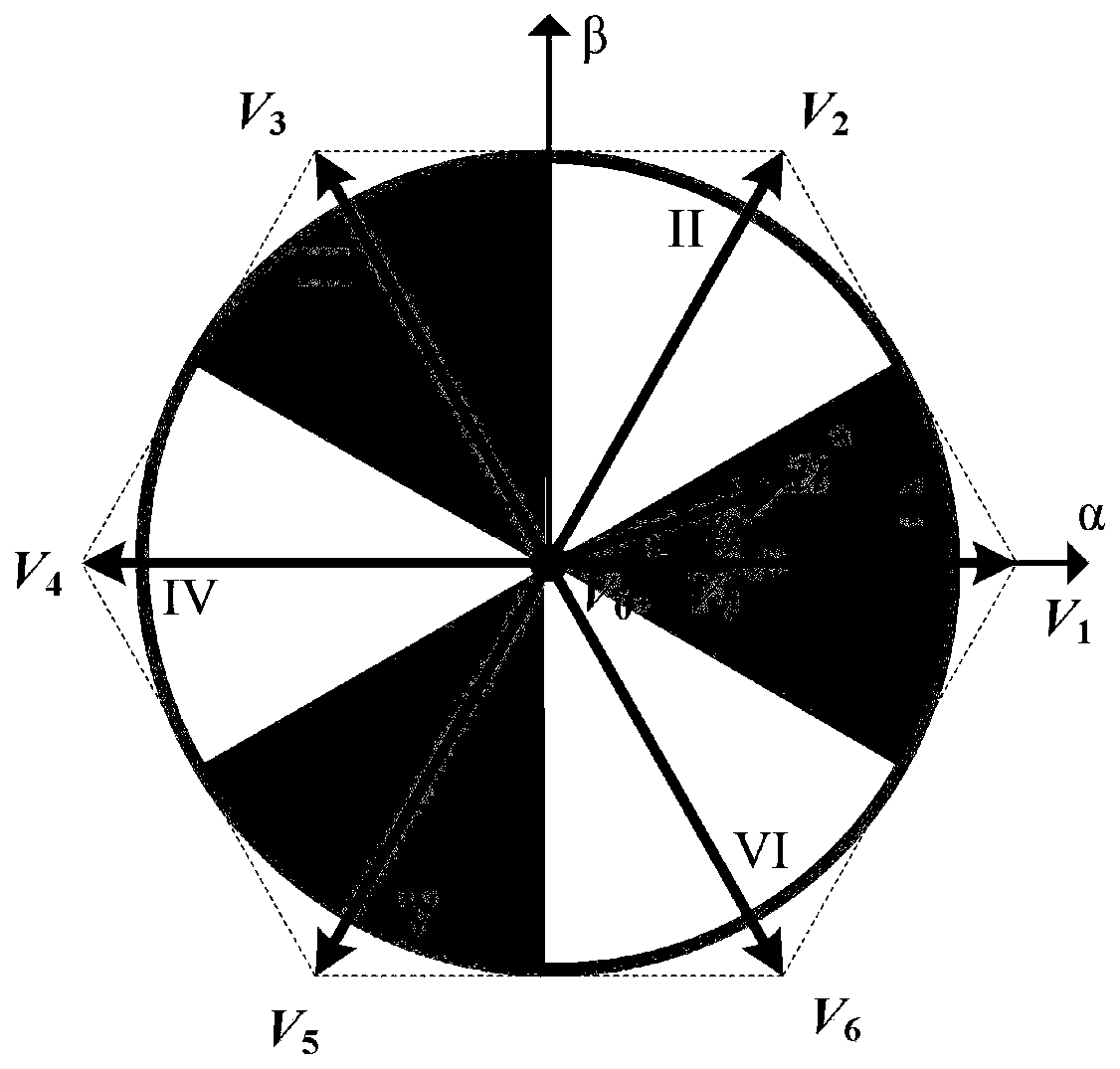

[0081] Based on the idea of unified modeling, the present invention proposes a finite control set model prediction contour control strategy suitable for a two-axis or three-axis feed drive system. First, the mechanical equation of the kinematic mechanism of the two-axis or three-axis feed drive system is combined with the motion equation of the drive motor, the electrical equation, and the change rate equation of the contour error to establish a unified model based on the discrete Taylor series; Calculate the amount of calculation, determine an appropriate number of alternative voltage vectors with tracking error as the main index; then construct a unified value function for a two-axis or three-axis feed drive system with contour error, motor operating performance, and current amplitude limit as evaluation indicators. Realize multi-variable collaborative optimization control; then use the principle of value function minimization to select the optimal voltage vector from the a...

Embodiment 2

[0092] For the finite control set model predictive contour control method of the dual-axis feed drive system, the unified model of the dual-axis feed drive system and the finite control set model predictive contour controller are as follows:

[0093] 1. Construct a unified model of dual-axis feed drive system based on discrete Taylor series:

[0094] Based on the idea of unified modeling, the two permanent magnet synchronous motors driving the x and y axes are considered as a whole, and a unified model of the dual-axis feed drive system is established. Firstly, the moving parts and the motion equations of the two drive motors in the experimental platform of the dual-axis feed drive system are modeled, which can be expressed as:

[0095]

[0096]

[0097] In the formula, p i is the expected position of the trajectory; M i is the equivalent mass of the motion mechanism; C i is the viscous friction coefficient of the motion mechanism; f i is the driving force to drive t...

Embodiment 3

[0136] The finite control set model prediction contour control method of the three-axis feed drive system is the same as that of Embodiment 2, and the unified model and value function of the three-axis feed drive system are as follows:

[0137] The unified model of the three-axis feed drive system is:

[0138]

[0139] In formula (15), x=[i dx i qx ω x θ x i dy i qy ω y θ y i dz i qz ω z θ z ε] T ;u=[u dx u qx u dy u qy u dz u qz ] T ; η = L x no x / 2π·(ω x * -ω x )+L y no y / 2π·(ω y * -ω y )+L z no z / 2π·(ω z * -ω z ); i di is the d-axis current of the motor; i qi is the q-axis current of the motor; ω i is the mechanical angular velocity of the rotor; θ i is the mechanical angle of the rotor; ε is the contour error; u di is the d-axis component of the stator voltage, u qi is the q-axis component of the stator voltage; L i is the contour error coefficient, n i is the displacement of the slider movement corre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com