Workpiece detection auxiliary device

An auxiliary device, workpiece detection technology, applied in optical components, optics, instruments, etc., can solve problems such as inconvenience and poor versatility, and achieve the effect of adjusting the degree of convergence or divergence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The following are specific embodiments of the present invention, and in conjunction with the accompanying drawings, further describe the technical solution of the present invention, but the present invention is not limited to these embodiments.

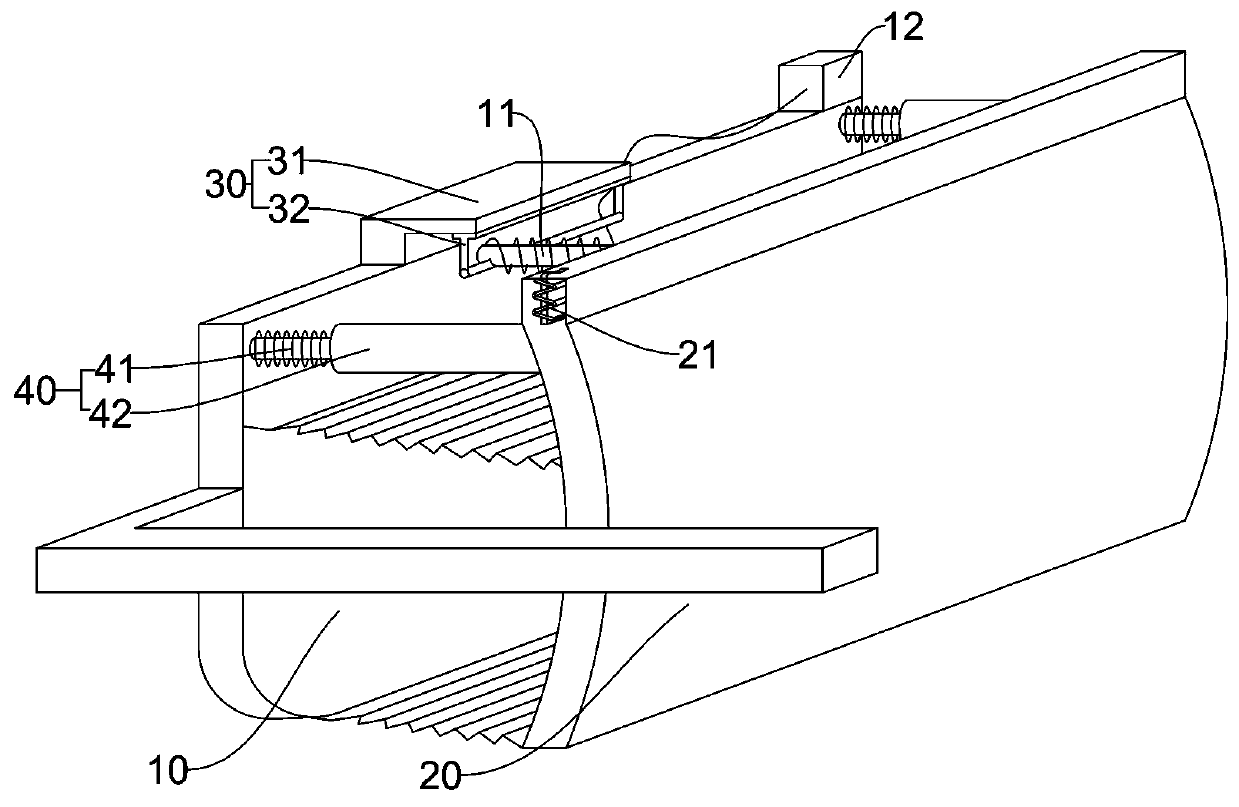

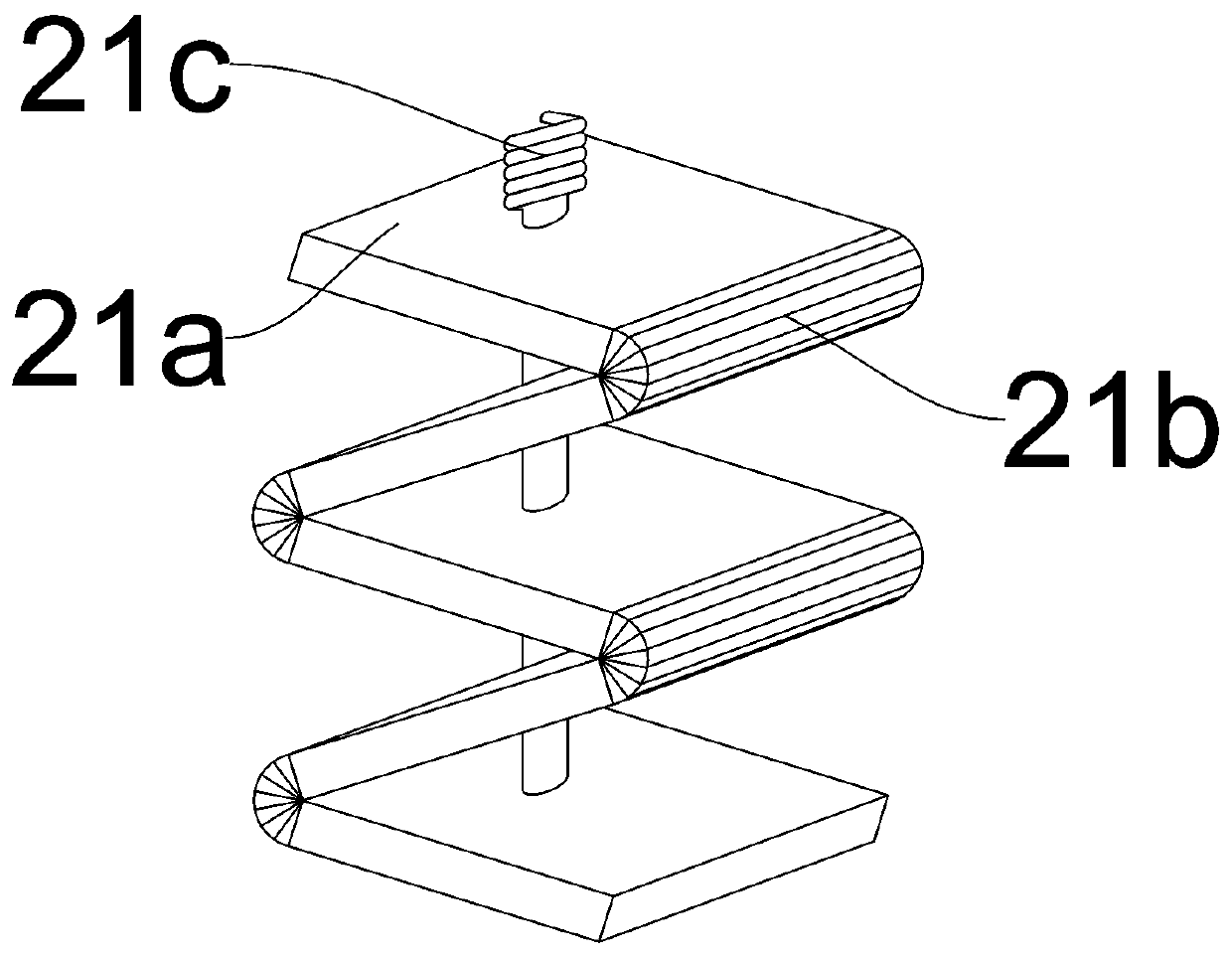

[0020] A workpiece detection auxiliary device, such as figure 1 As shown, it includes a mounting frame arranged at the light-emitting end of the laser generator and a lens 10 arranged on the mounting frame, and also includes a deformable adjusting piece 20 arranged between the lens 10 and the laser generator, and between the lens 10 and the adjusting piece 20 An adjustment cavity filled with adjustment fluid is formed between them, the adjustment piece 20 is provided with a magnetic piece 21 with magnetism, and the lens 10 is provided with an electromagnet 11 . The laser light emitted by the laser generator passes through the adjusting plate 20, the adjusting cavity, and the lens 10 in sequence before being emitted.

[0021] a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com