Armored fiber jumper laser armor stripping device

A laser and fiber jumper technology, applied in light guides, optics, instruments, etc., can solve the problems of irregular armor cutting, slow operation speed, and affecting production efficiency, and achieve uniform lengths, improve work efficiency, and facilitate standardization.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described below in conjunction with the accompanying drawings, but the protection scope of the present invention is not limited to the following description.

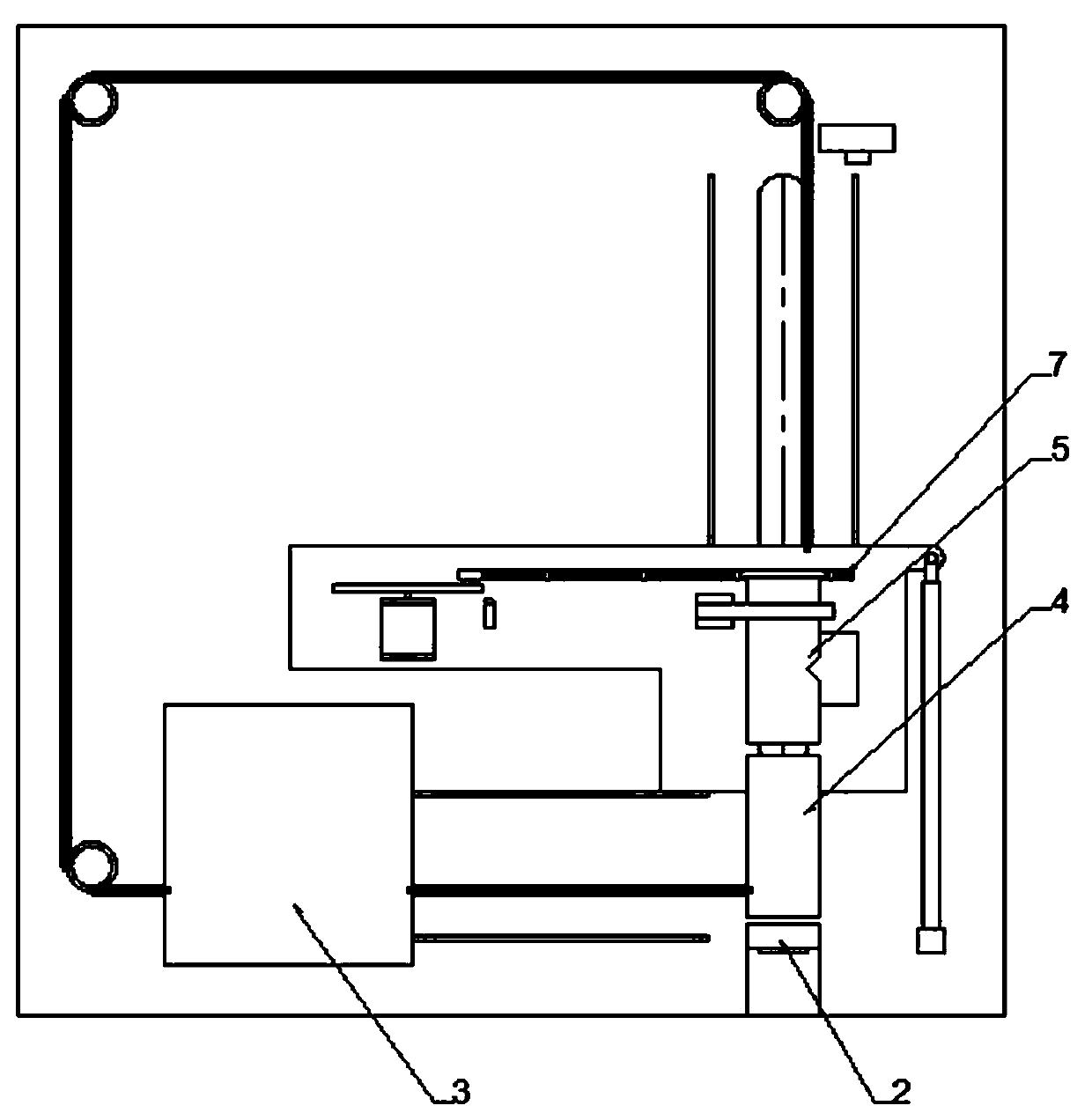

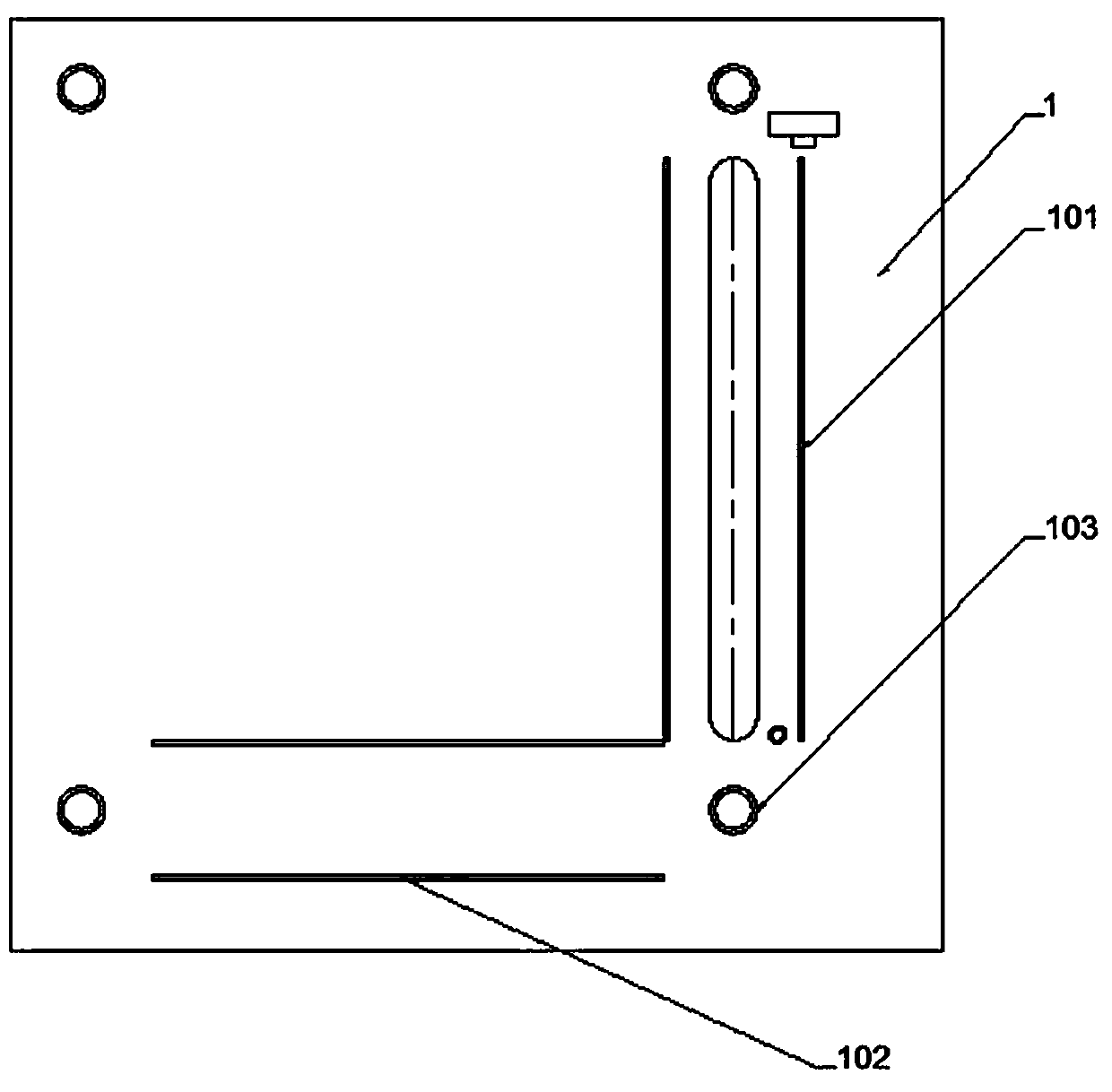

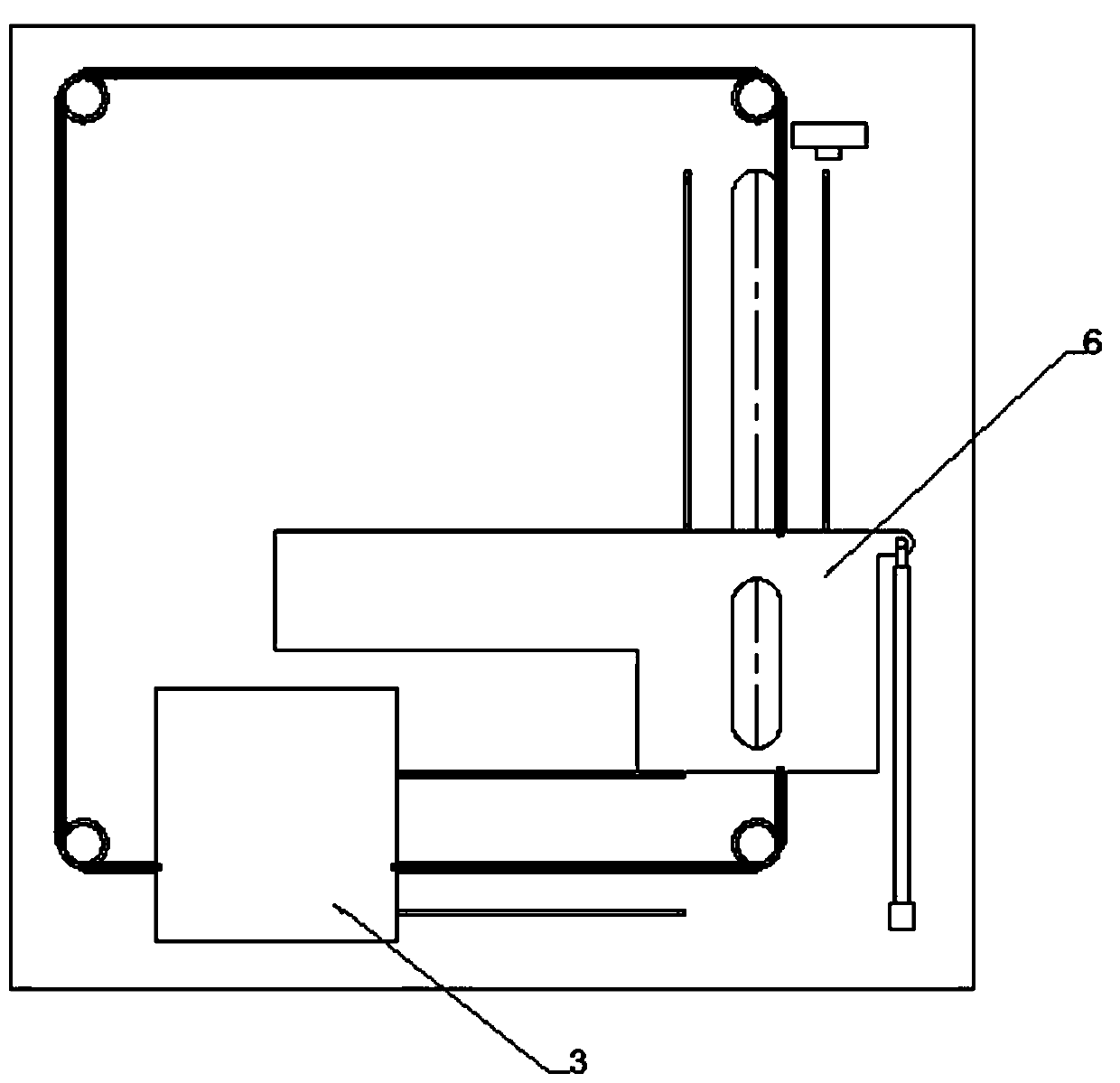

[0031] Such as figure 1 As shown, an armored fiber jumper laser armor stripper for armored fiber jumpers, including a base 1, a fixing fixture 2, a sheath cutter 4, an aramid cutter 3, a steel armor cutter 5 and a slide plate 6 ; The base 1 is provided with a longitudinal slide rail 101 and a transverse slide rail 102, and the outer skin shearer 4 and the steel armor cutter 5 are all arranged on the slide plate 6, so that the outer skin shearer 4 and the steel armor cutter 5 The distance is fixed, which can ensure that the length of the optical fiber after each peeling is consistent. The bottom of the slide plate 6 is provided with a groove that cooperates with the longitudinal slide rail 101 and is connected with the longitudinal slide rail 101. The bottom of the aramid cutt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com