Yarn adjusting head

A technology for thread adjustment and thread head, which is applied in the field of thread head adjustment, which can solve the problems of energy loss, inability of thread adjustment head to work stably, and inability to overcome the tension of the reset spring, etc., and achieve the effect of reasonable structural design and high stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention is described in detail below in conjunction with accompanying drawing description:

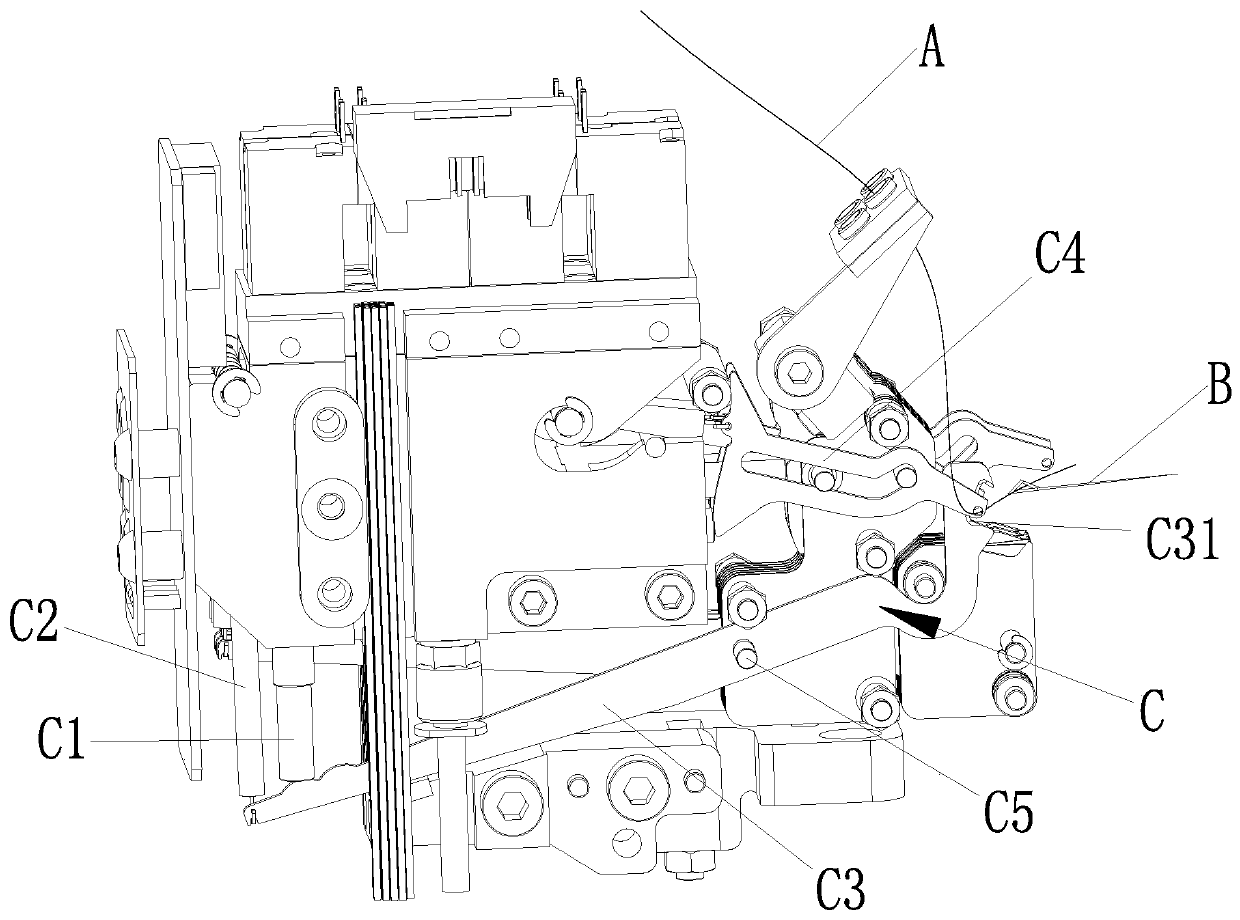

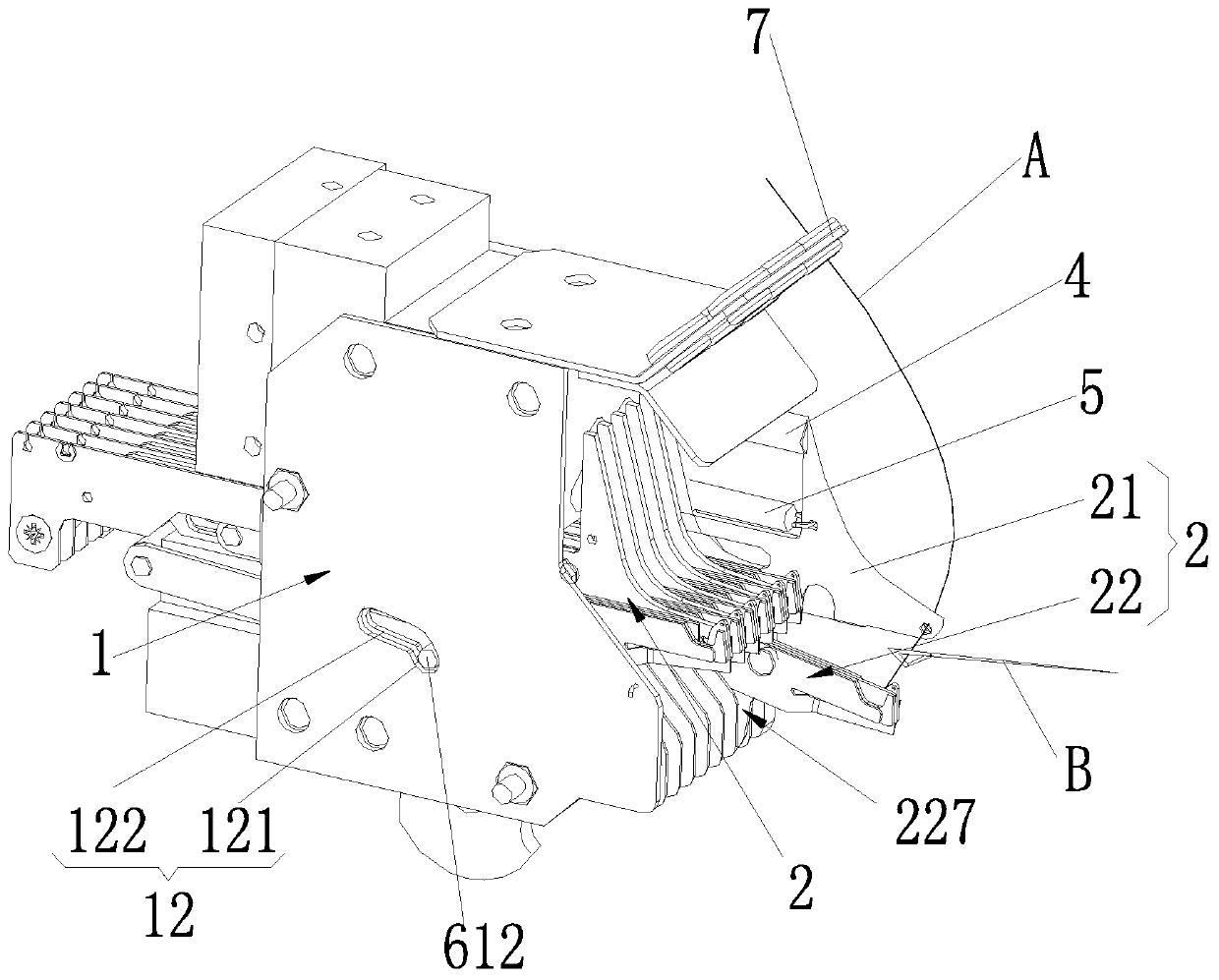

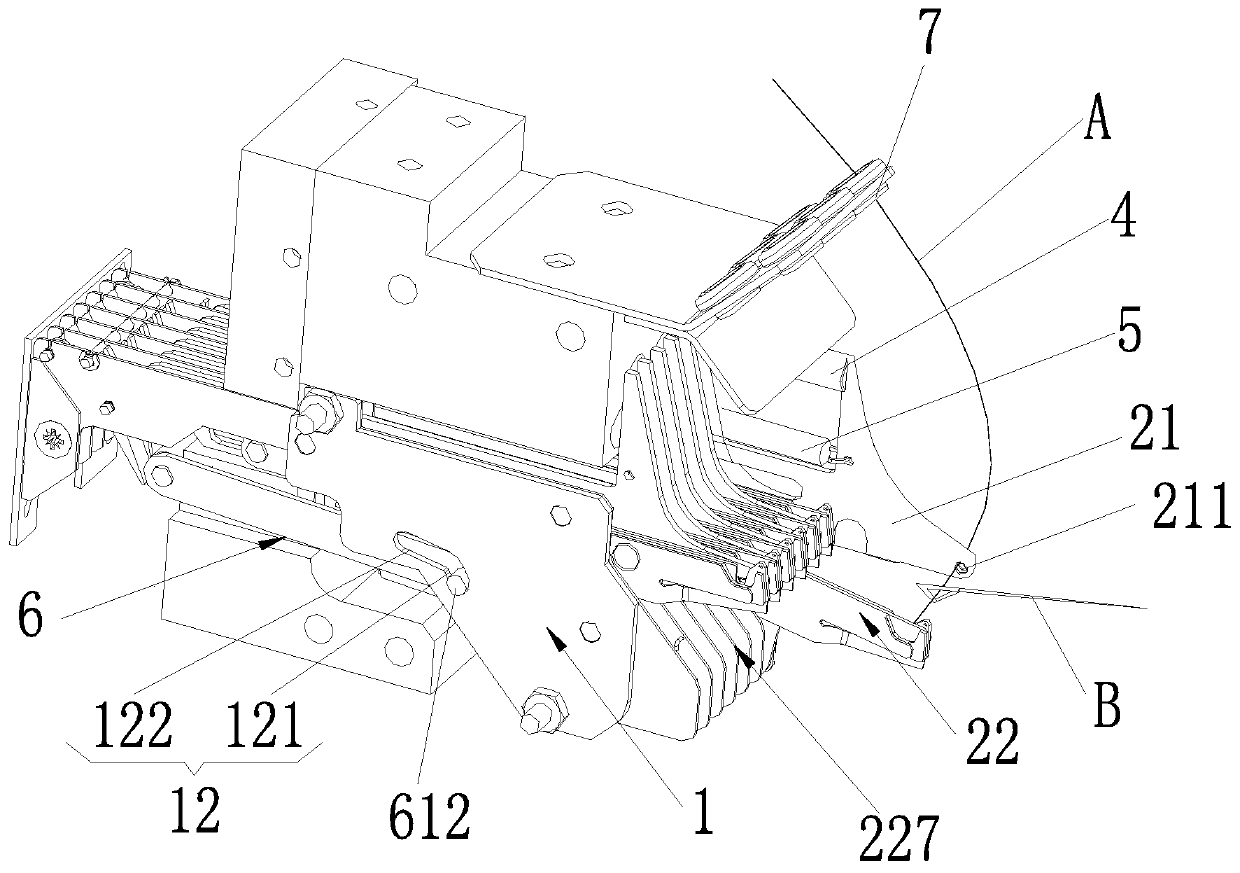

[0037] Such as Figure 2-10 As shown, a thread adjusting head of the present invention is characterized in that it includes a base 1 and more than one set of thread adjusting mechanisms 2 arranged on the base 1, and each set of thread adjusting mechanisms 2 includes a yarn feeder plate 21 and a yarn feeder Plate 21 cooperates with the scissors assembly 22 that is set, the front end of the yarn feeder plate 21 is provided with a threading hole 211, the free end of the yarn A passes through the threading hole 211 and is clamped and fixed on the scissors assembly 22. The yarn feeder plate 21 is slidably connected to the base 1 and can slide back and forth relative to the base 1, and the rear end of the yarn feeder plate 21 is provided with a first slot 212 extending in the front and rear direction, and the rear end of the scissors assembly 22 A first pin shaft 221 ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com