Composite yarn

A yarn and yarn weaving technology, applied in the direction of yarn, textiles and papermaking, etc., can solve the problems of complex preparation, incapable of small-scale production, long production time, etc., and achieve the effect of simple preparation method, convenient operation and improved antibacterial property

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be specifically introduced below in conjunction with the accompanying drawings and specific embodiments.

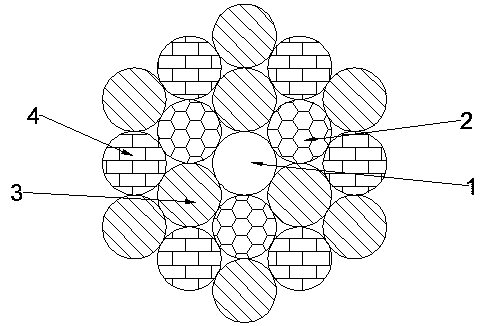

[0016] A composite yarn, comprising a body, characterized in that the body includes silk, and the outer ring of the silk is provided with a weaving layer, and the weaving layer includes three polyester yarns and three viscose yarns, the polyester yarn and The viscose yarns are arranged alternately, the outer ring of the weaving layer is provided with an antibacterial layer, the antibacterial layer includes six antibacterial fibers and six viscose yarns, the antibacterial fiber is bamboo charcoal fiber, and the bamboo charcoal fiber has a good antibacterial effect. Viscose yarn and antibacterial fiber are arranged alternately, and the diameter ratio of silk, polyester yarn, viscose yarn and antibacterial fiber is 1:1:1:1.

[0017] A processing technology for composite yarn, characterized in that it includes the following steps: Step (1), p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com