High-safety material lifting device for building construction

A material and bottom plate technology, used in lifting devices, lifting equipment safety devices, lifting frames, etc., can solve problems such as poor stability and safety, and achieve the effects of increasing efficiency, preventing materials from falling, and prolonging service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

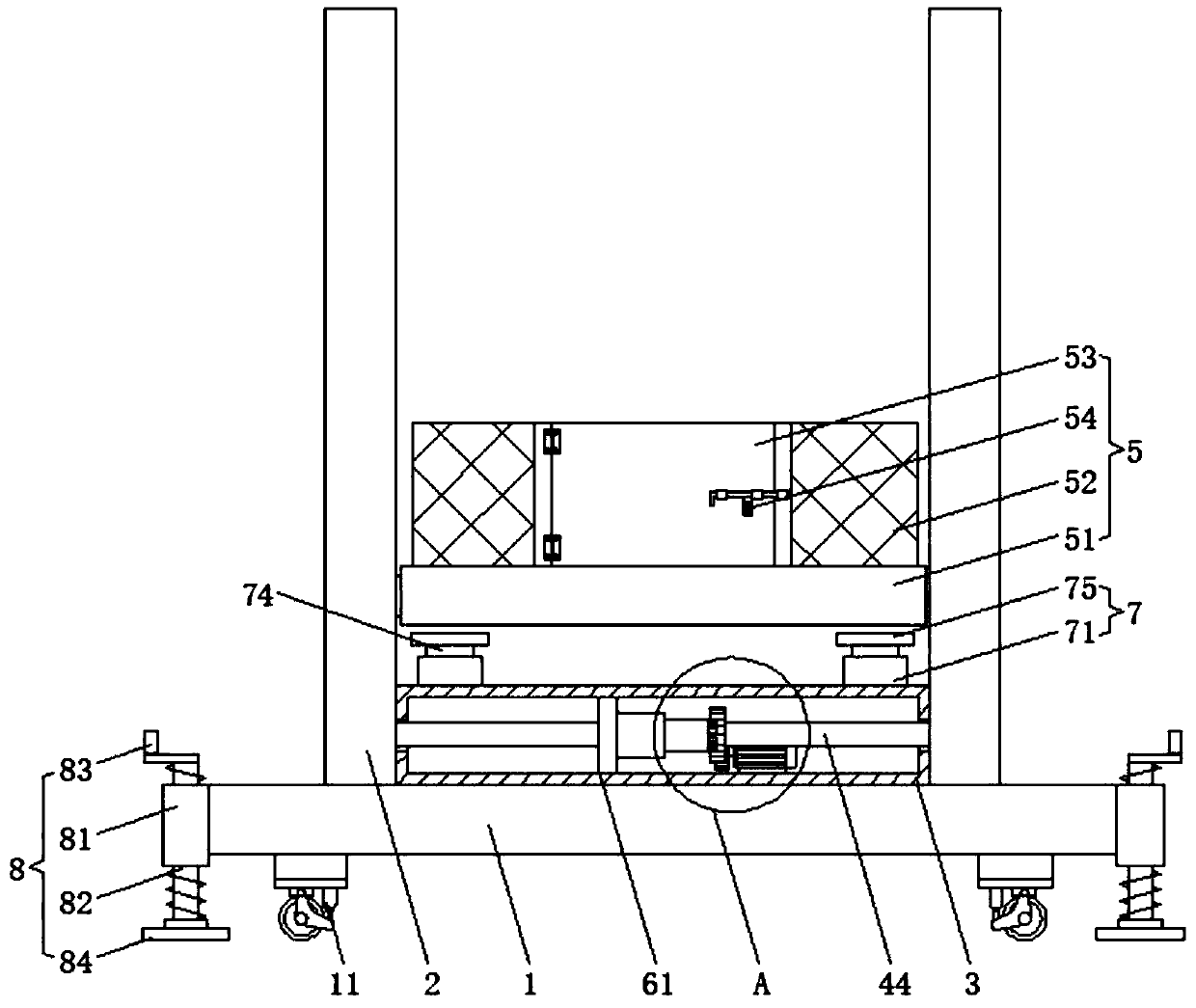

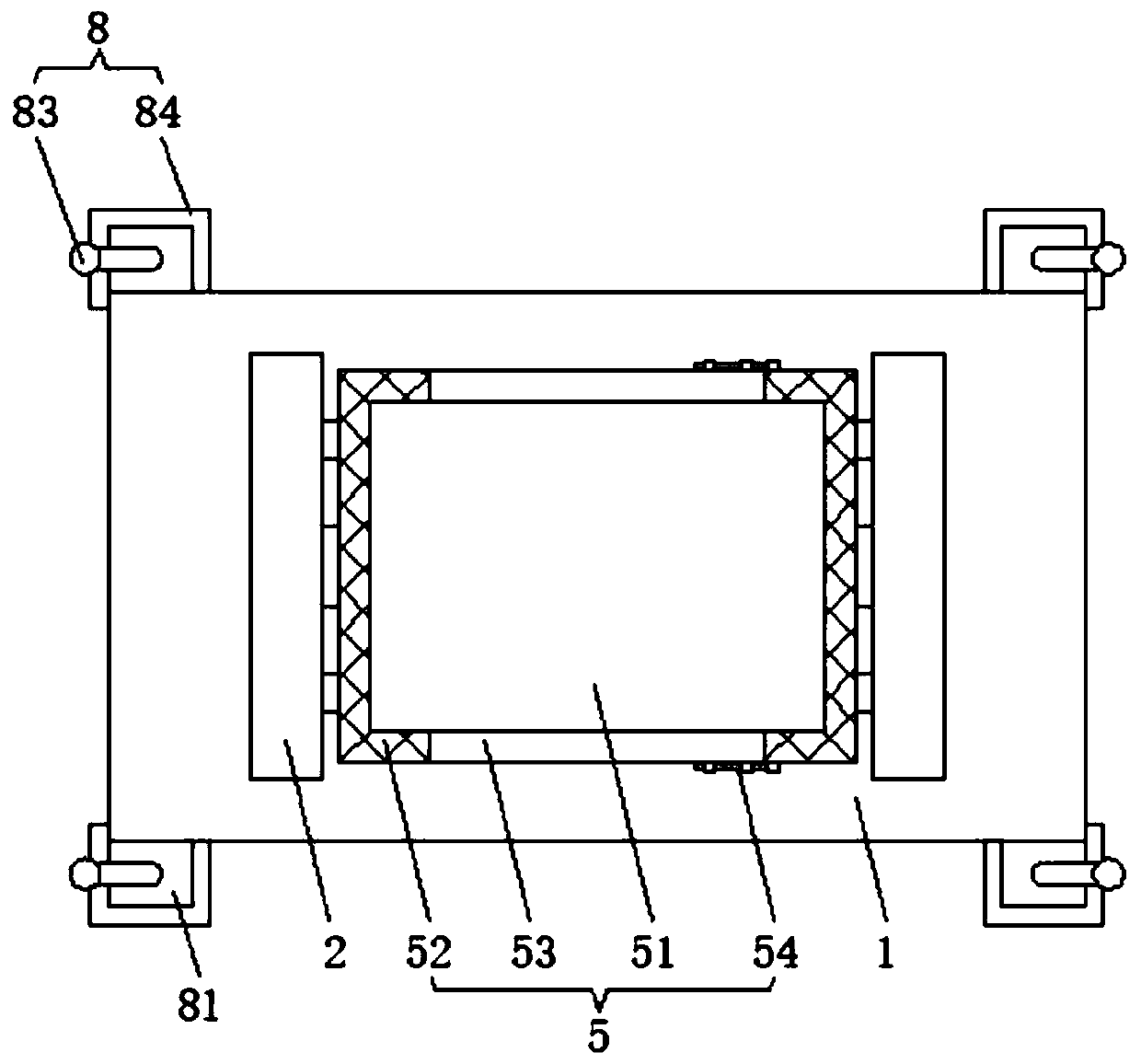

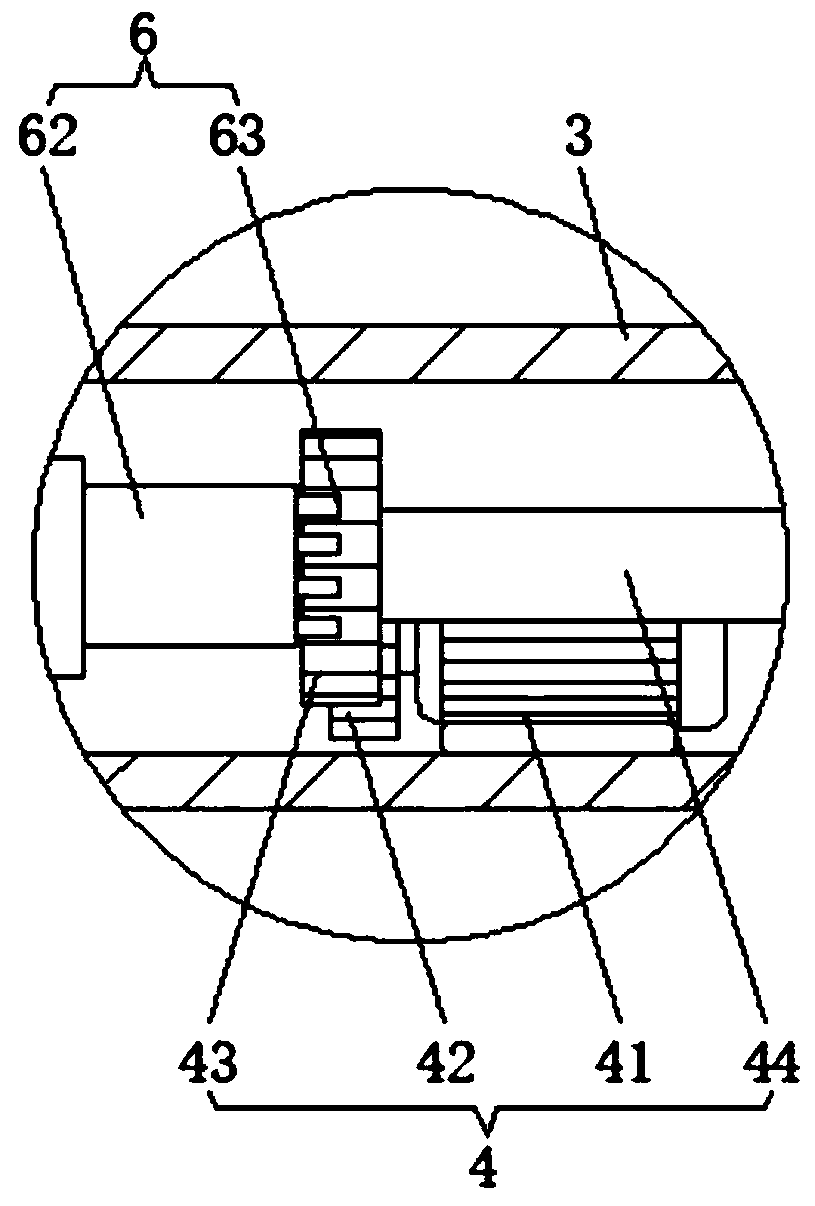

[0032] Such as figure 1 , The material lifting device for building construction includes a bottom plate 1 , and a plurality of wheels 11 and a plurality of support components 8 are arranged on the bottom of the bottom plate 1 . The support assembly 8 includes a sleeve 81 , a screw rod 82 , a rocker 83 , and a leg 84 . The leg 84 is fixedly connected to the lower end of the screw rod 82 , the upper end of the screw rod 82 is connected to the rocker 83 , the screw rod 82 is screwed to the sleeve 81 , and the sleeve 81 is fixedly connected to the bottom plate 1 . The feet 84 are movable between an extended position and a telescopic position. The rocking bar 83 is manually shaken to drive the screw mandrel 82 to rotate upwards, and the supporting leg 84 is lifted off the ground under the drive of the screw mandrel 82, so that the material lifting device is only supported on the ground by the wheels 11, so that it is convenient to move. After the material lifting device moves to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com