Large-span bulk material conveying system

A conveying system and large-span technology, applied in the field of conveyors, can solve the problems of waste of resources and efficiency, large consumables, and inability to realize multi-level variable counterweights, and achieve cost-saving effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0057] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

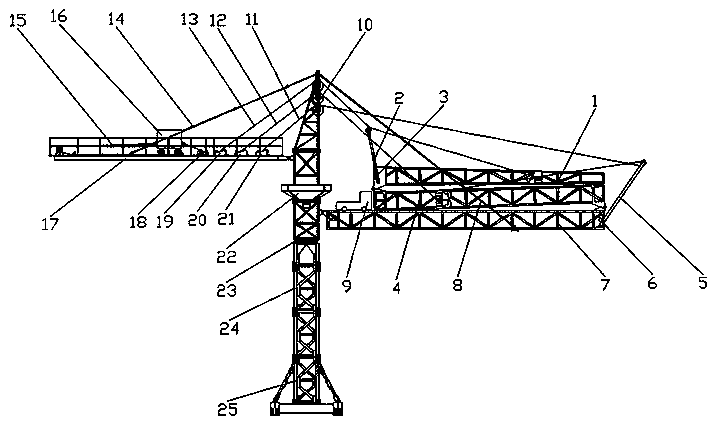

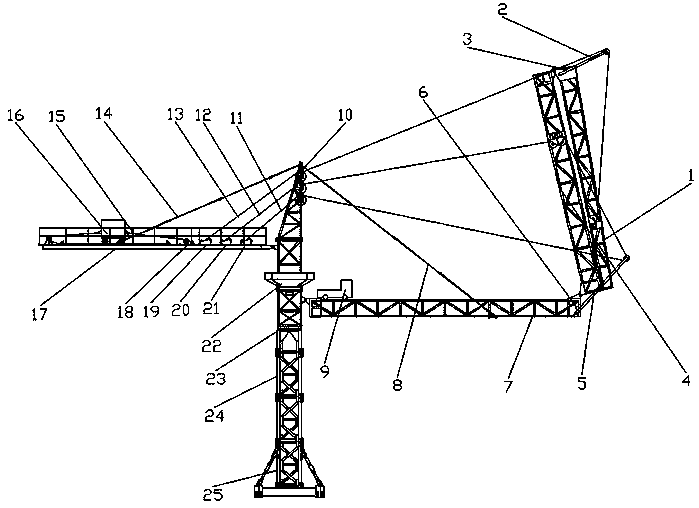

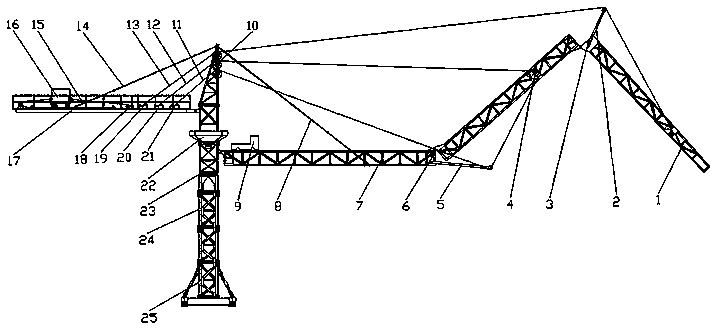

[0058] As shown in the figure: a large-span bulk material conveying system, including folding arm conveyor and cross-dyke lifting feeding conveying equipment. The folding arm conveyor includes a three-section conveying arm, a tower top 10 , a balance arm 17 , a tower body 24 , and an underframe 25 . It also includes a winch, a steel wire rope, a gantry, and a limit device; the underframe 25 is fixedly installed in the stockyard through anchor bolts, and the tower body 24 is also connected with the underframe 25 through bolts; the three-section conveying arms are respectively The first conveying arm 7, the second conveying arm 4, and the third conveying arm 1, wherein the first conveying arm 7 is installed on the tower body 24 through a pin shaft, and the second conveying arm 4 is connected to the first conveying arm 7 through a pin shaft , the third co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com